Carbon fiber reinforced composite cable for intelligent industrial robot and production process thereof

A technology for industrial robots and composite cables, which is applied in the direction of cable/conductor manufacturing, insulated cables, and bendable cables, etc., which can solve the performance requirements of industrial robot cables for wear resistance, tearing, high flexibility and torsion resistance Higher problems, to achieve the effect of increasing softness, simple and novel structure, and increasing toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

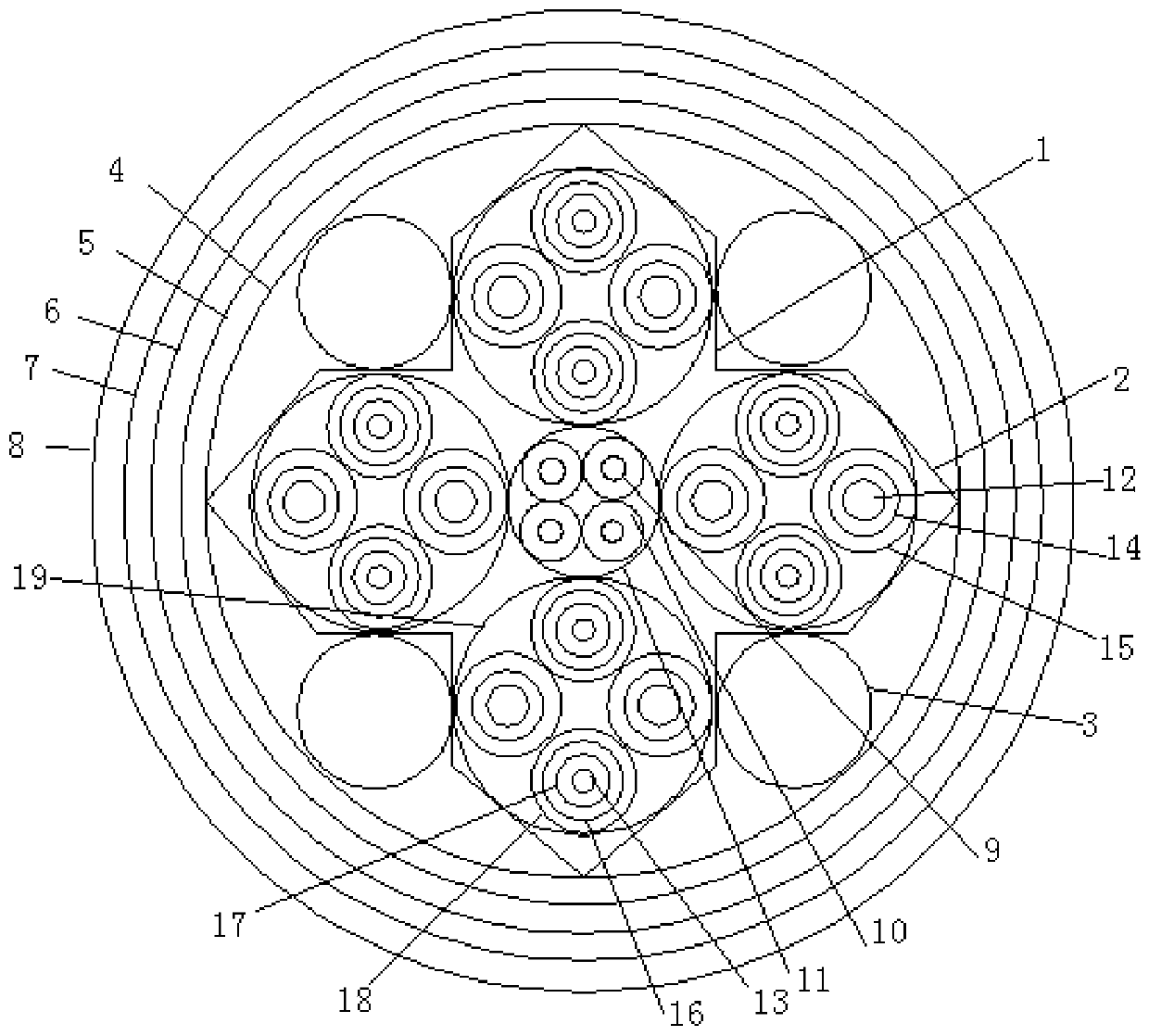

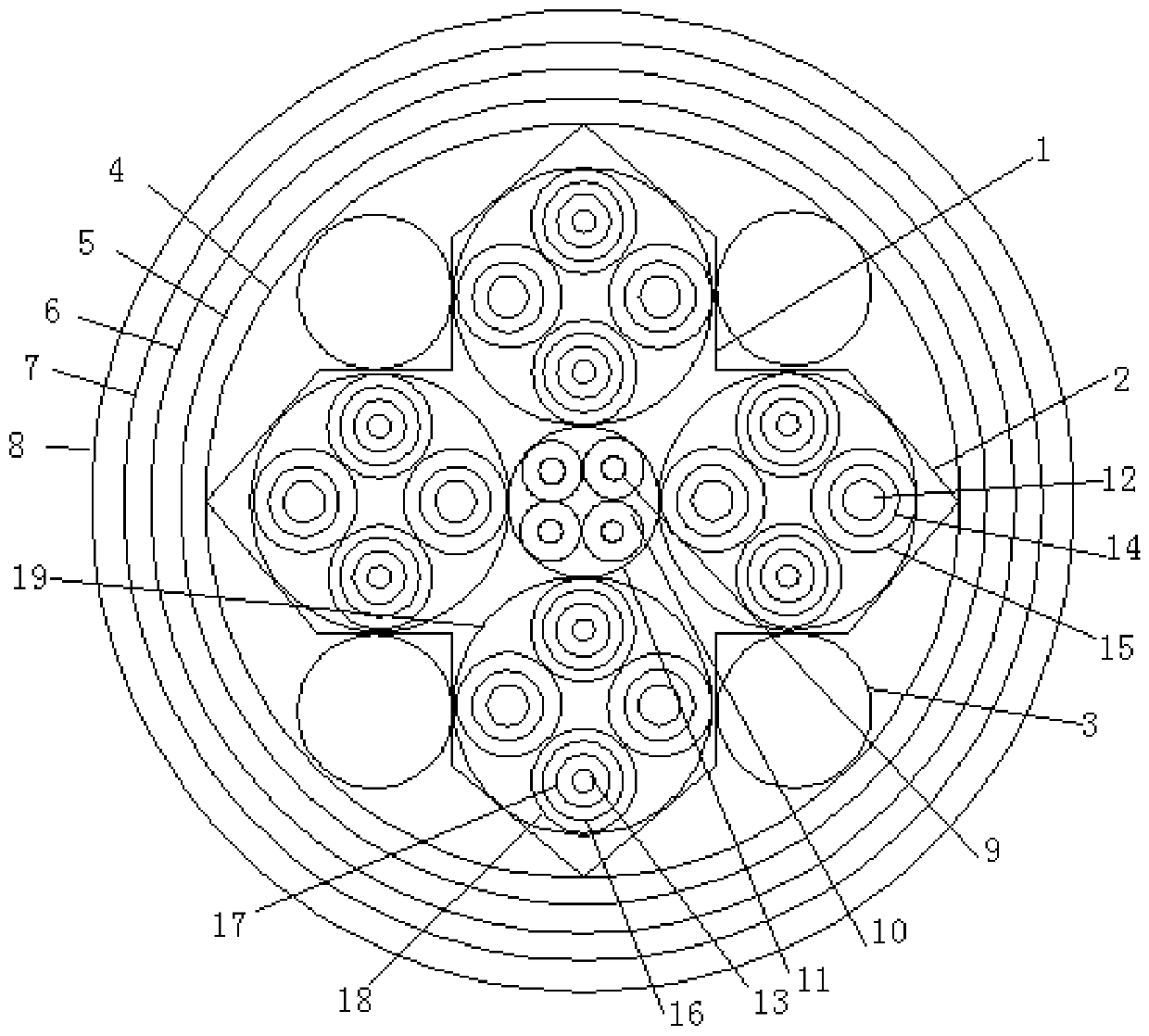

[0015] Such as figure 1 As shown, a carbon fiber-reinforced composite cable for intelligent industrial robots includes a rubber skeleton 1, the rubber skeleton 1 is a hollow cross, and a core 1 is provided at the inner center of the rubber skeleton 1, and around the core 1 Wire cores 2 are evenly distributed, and tapered sealing plates 2 are respectively provided on the four sides of the rubber skeleton 1, and polyurethane elastic rods 3 are respectively arranged at the four outer corners of the rubber skeleton 1, and the outer sides of the rubber skeleton 1 are covered sequentially. There are cross-linked ethylene tetrafluoroethylene copolymer insulation layer 4, carbon fiber wire and tinned steel wire mixed braided sheath 5, nano silicon waterproof glue filling layer 6, aluminum alloy belt interlocking armor layer 7 and chlorosulfonated polyethylene outer sheath 8. The core one includes a conductor one 9, and the outside of the conductor one 9 is coated with a halogen-free e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com