A connection component of bridge wet joint construction formwork

A technology for connecting components and wet joints, which is applied in the field of formwork docking, can solve the problems of time-consuming and laborious formwork fixing, inconvenient concrete pouring, difficulty in formwork disassembly, etc., and achieve the effect of improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

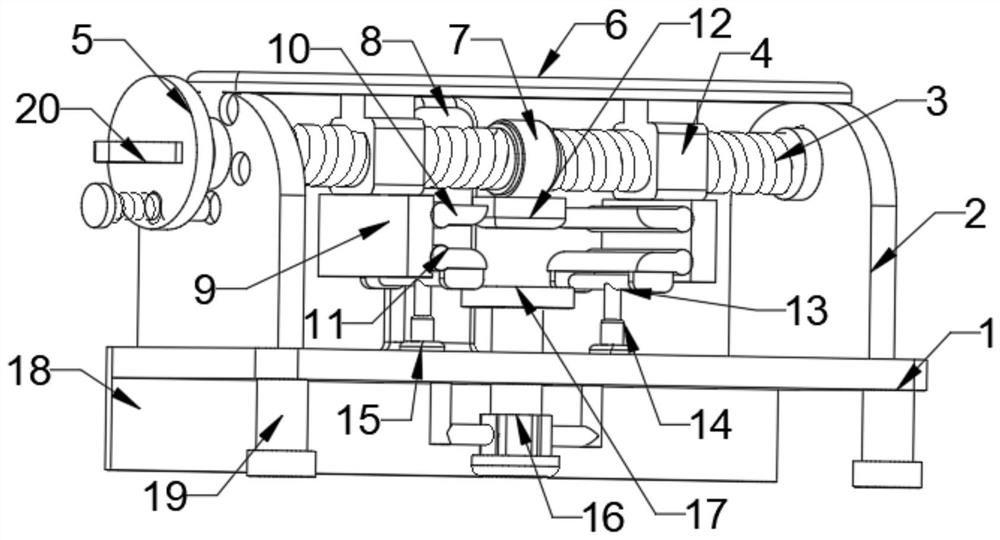

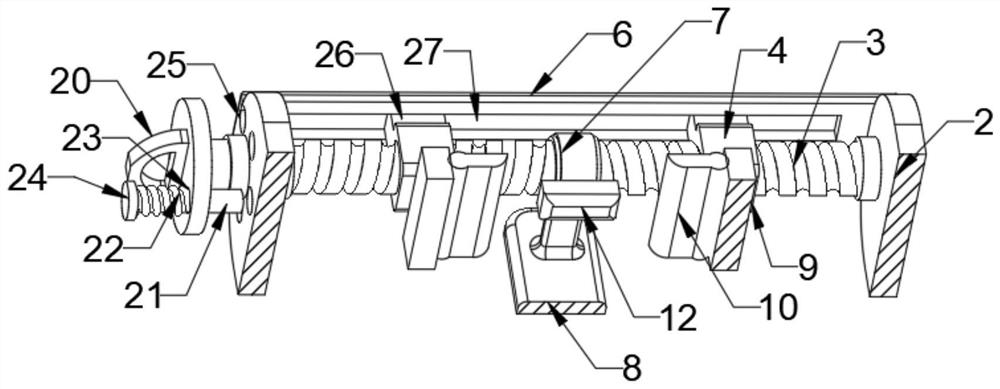

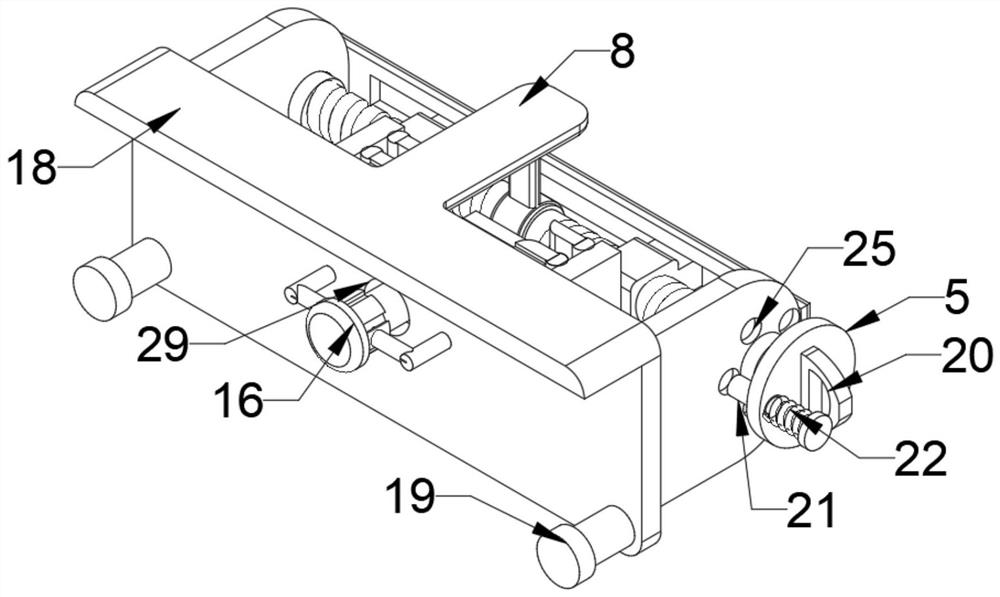

[0026] refer to Figure 1 to Figure 4 , a connection assembly of a bridge wet joint construction formwork, comprising a base 1, a bearing plate 2 is fixedly connected to both sides of the top of the base 1, and a screw 3 is arranged between the two bearing plates 2, and one end of the screw 3 passes through a rotating shaft It is rotationally connected with one of the two bearing plates 2, and the other end of the screw rod 3 passes through the side wall of the other bearing plate 2 through a bearing sleeve, and the extension end of the screw rod 3 is fixedly connected with a rotating plate 5, and ...

Embodiment 2

[0035] The inventors have found in practice that more and more bridge buildings use prestressed concrete beam block structures, and then assemble them into large-span continuous beams through wet joints, because the prestressed concrete beam block structures are under load. It can improve the tensile capacity of concrete under load, that is, to make up for the lack of tensile strength by means of the high compressive strength of concrete, prevent or delay the appearance of concrete cracks, and increase the strength of the structure. rigidity, save steel and cement, and the prestressed stress is usually realized by stretching the steel bars, so the prestressed concrete beam block structure has a certain bending arc when used, and the wet bridge provided in the first embodiment The connection components of the joint construction formwork cannot clamp the construction formwork according to the bending radian of the prestressed concrete beam block structure during use. In view of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com