Front auxiliary frame mounting bracket assembly structure of fuel cell hydrogen energy automobile

A technology for mounting brackets and front subframes, applied in the substructure, vehicle components, transportation and packaging, etc., can solve the problems of difficulty in reduction, high mold cost, heavy weight, etc., to reduce the weight of parts, reduce the length of the cantilever, The effect of low production line cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

[0022] An embodiment of the present invention provides a mounting bracket assembly structure for a front sub-frame of a fuel cell hydrogen energy vehicle.

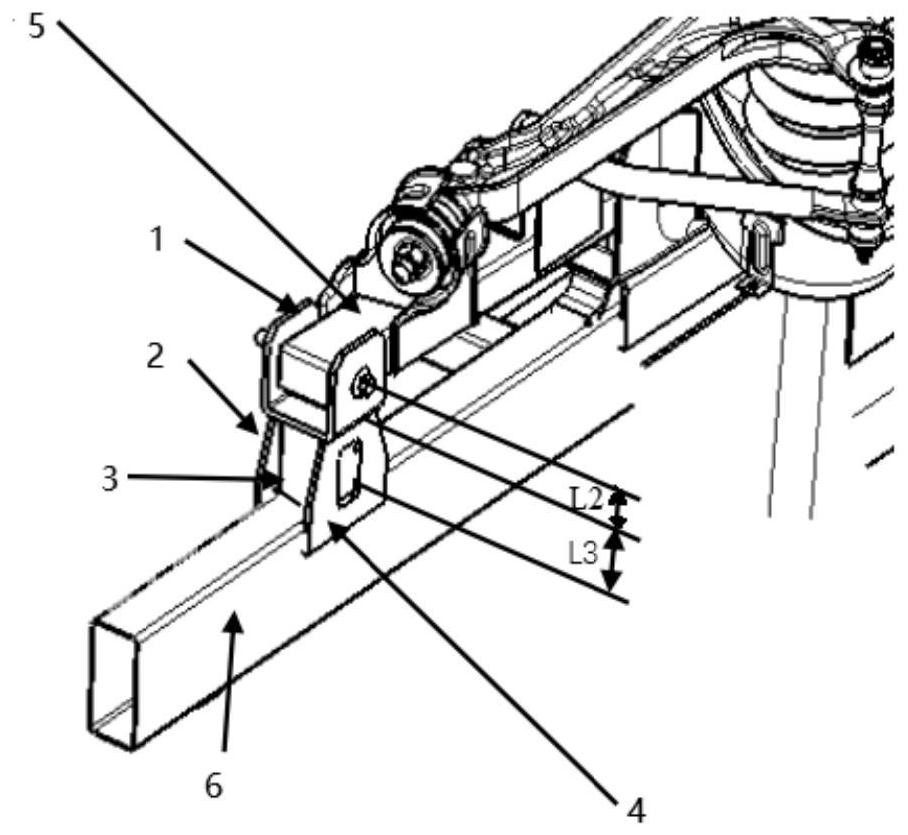

[0023] Please refer to figure 1 , figure 1 It is a schematic diagram of a fuel cell hydrogen energy vehicle front subframe mounting bracket assembly structure in an embodiment of the present invention, a fuel cell hydrogen energy vehicle front subframe mounting bracket assembly structure, the front subframe mounting bracket The assembly is connected with the front longitudinal beam 6 through carbon dioxide shielded welding. The front sub-frame mounting bracket assembly includes: front sub-frame mounting bracket 1, mounting bracket right reinforcement plate 2, mount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com