1000 MW reactor coolant pump lifting hook conversion device

A coolant pump and conversion device technology, applied in the directions of transportation and packaging, load hoisting components, etc., can solve the problems of 1000MW reactor coolant pump lifting limitation, complicated and complicated operation process of crane replacement hook, affecting work efficiency, etc. The effect of shortening lifting time, shortening working time and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

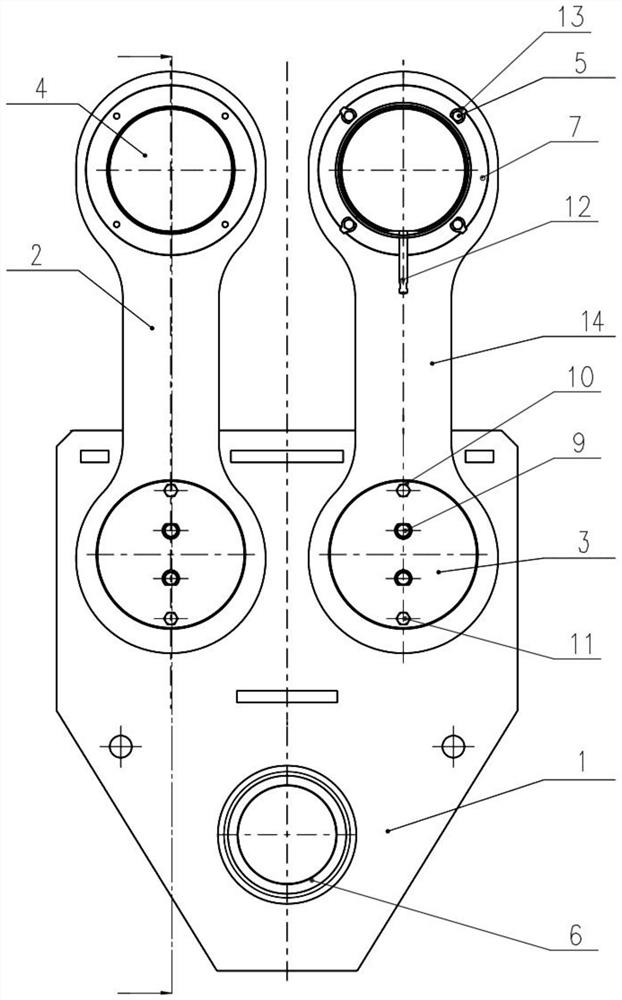

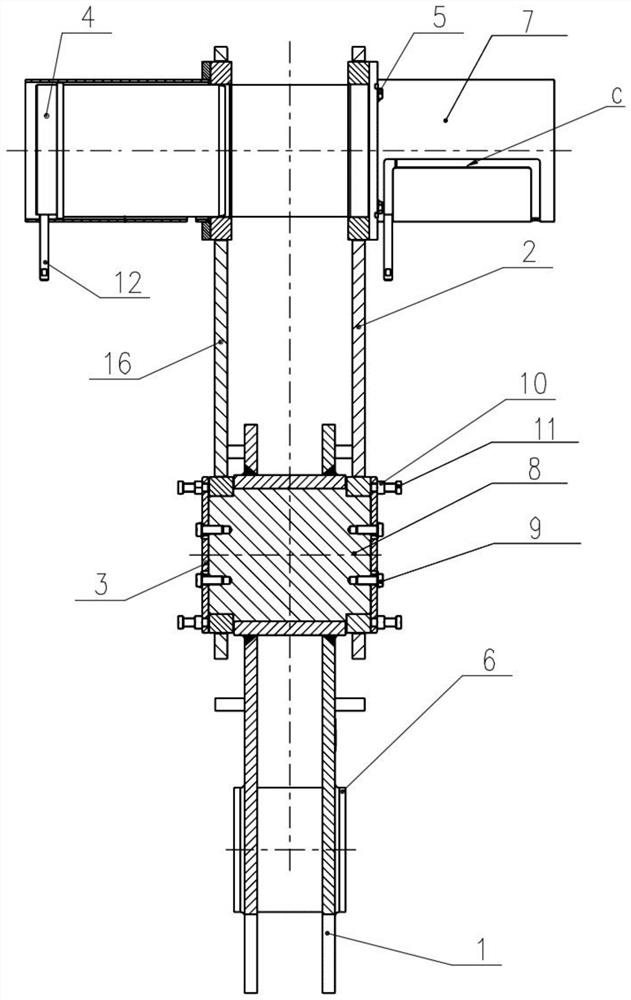

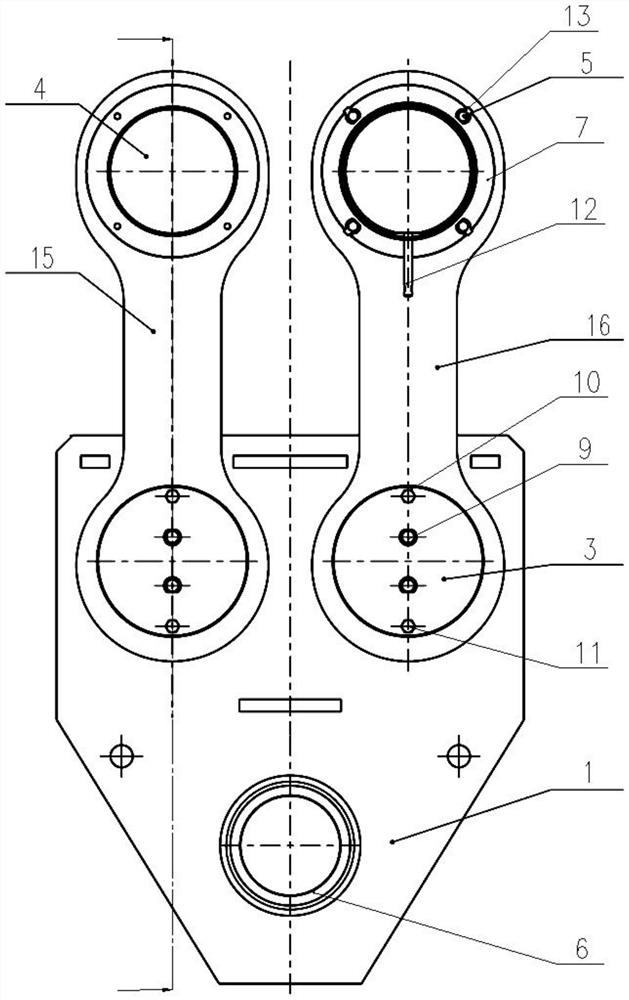

[0016] Such as figure 1 Shown is a 1000MW reactor coolant pump hook conversion device, the device is a vertical structure, the connecting sleeve 6 penetrates into the hole in the lower part of the conversion seat 1, and is welded with the conversion seat 1 as a whole; the left pin 8 and the right Side pin 17 passes in the double hole of conversion seat 1 top, as figure 2 The shown first boom 2 and the second boom 16 are installed on the left latch 8, as Figure 4 The third boom 14 and the fourth boom 15 shown are installed on the right bolt 17, and the second hex head screw 9 passes through the threaded hole on the lock plate 3 to connect with the left bolt 8 and the right bolt 17 respectively. Fixedly connected, the third hexagonal head screw 11 cooperates with the hexagonal head nut 10 to pass through the threaded hole on the lock plate 3 to connect with the first boom 2, the second boom 16, the third boom 14, and the fourth boom respectively. Arm 15 is fixedly connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com