Environment-friendly sewage floating oil separation treatment equipment

A separation treatment and environmental protection technology, applied in water/sludge/sewage treatment, water treatment parameter control, liquid separation, etc., can solve the problems of complex treatment methods, slow treatment speed, troublesome, etc., to improve treatment efficiency and facilitate the The effect of refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

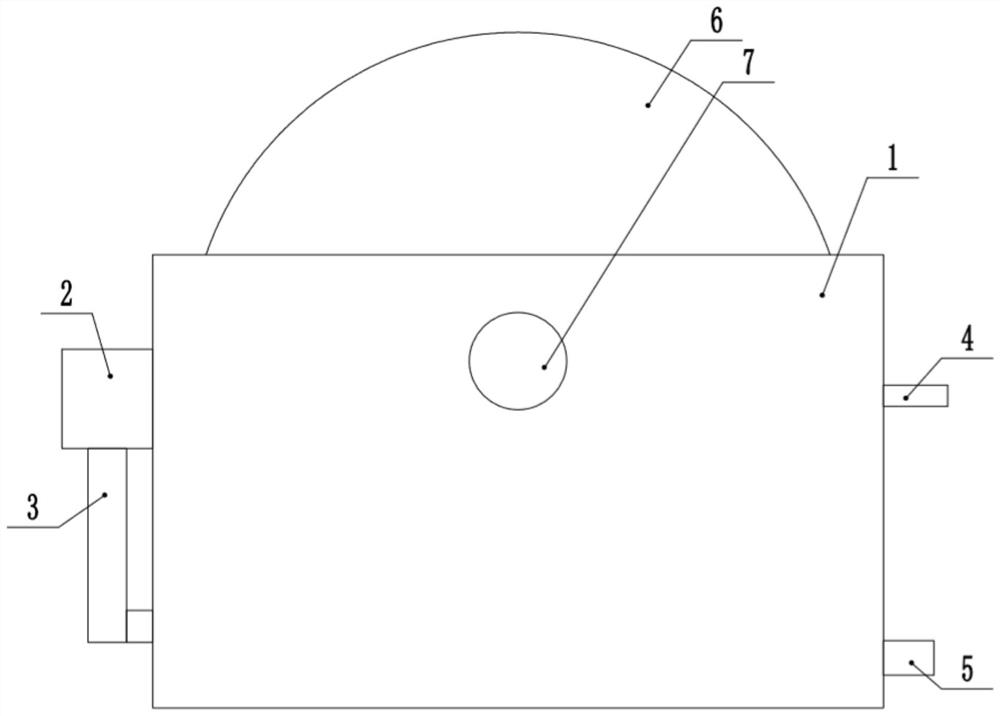

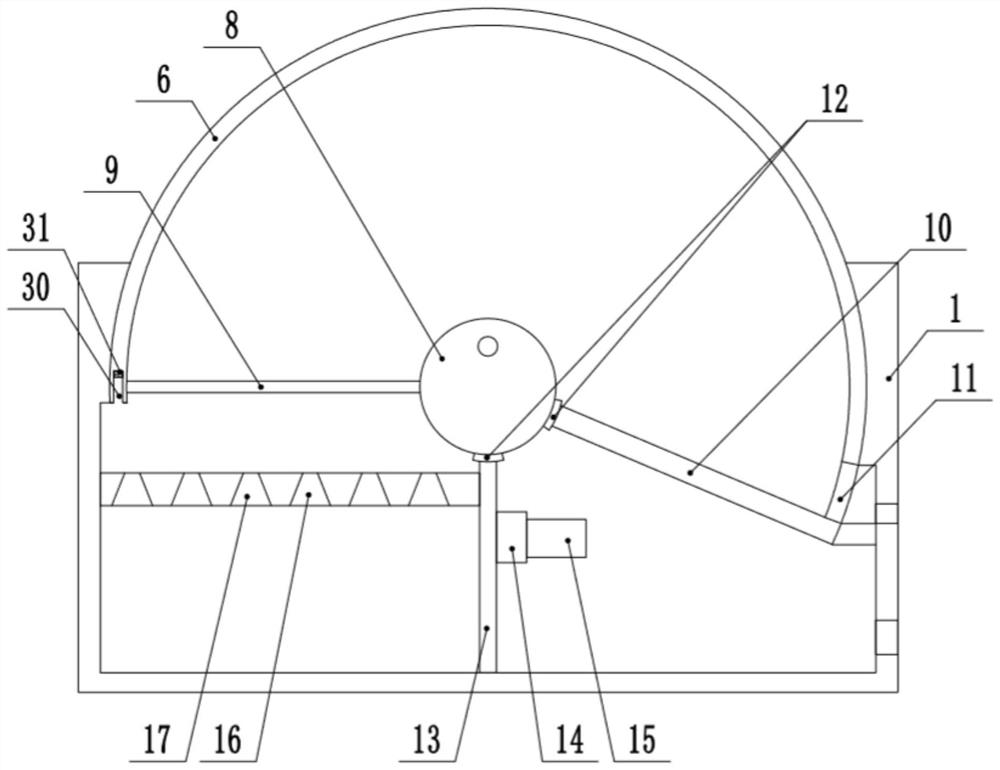

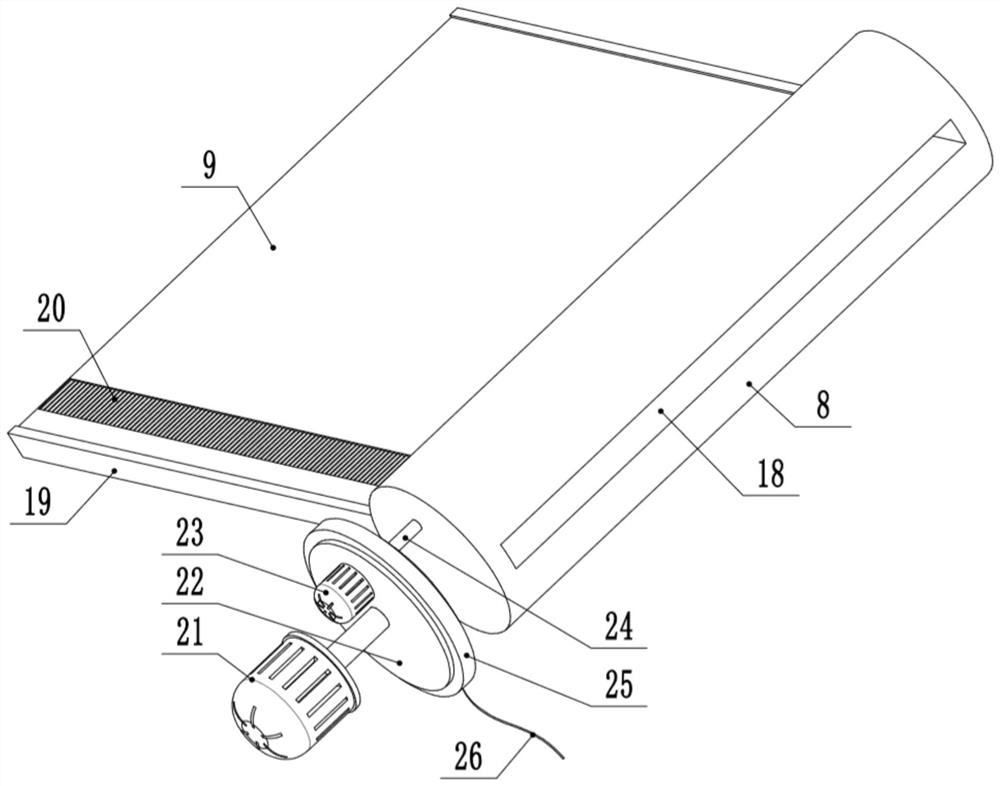

[0025] see Figure 1-4 , an environment-friendly sewage floating oil separation treatment equipment, comprising a treatment box 1, one side of the treatment box 1 is fixedly connected to the water inlet pump 2, the output end of the water inlet pump 2 is fixedly connected to the water inlet pipe 3 between the treatment box 1, and the treatment box 1 The top of the top cover 6 is fixedly connected to the top cover 6, and the top cover 6 is provided with an oil-removing mechanism, the outside of the processing box 1 is fixedly connected to the driving device 7, and the bottom end in the processing box 1 is fixedly connected to the partition plate 13, and the partition plate 13 will process the box 1 The interior is divided into a degreasing area and a drainage area arranged from left to right. A baffle plate 16 is arranged in the degreasing area. The oil hole 17, the dividing plate 13 is provided with a drain hole, the draining hole is provided with an electric valve 14, the ele...

Embodiment 2

[0031] see Figure 1-4 , the other content of this embodiment is the same as that of Embodiment 1, the difference is:

[0032] An environment-friendly sewage floating oil separation treatment equipment, comprising a treatment box 1, one side of the treatment box 1 is fixedly connected to the water inlet pump 2, the output end of the water inlet pump 2 is fixedly connected to the water inlet pipe 3 between the treatment box 1, and the side of the treatment box 1 The top is fixedly connected to the top cover 6, and the top cover 6 is provided with an oil-removing mechanism, the outside of the processing box 1 is fixedly connected to the driving device 7, and the bottom of the processing box 1 is fixedly connected to the partition plate 13, and the partition plate 13 will process the inside of the processing box 1. Divided into oil removal area and drainage area set from left to right, the oil removal area is provided with a baffle plate 16, the baffle plate 16 is fixedly connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com