Industrial circulating water pH automatic control device and control method

An automatic control device and industrial circulating water technology, applied in water treatment parameter control, chemical instruments and methods, neutralized water/sewage treatment, etc., can solve problems such as extensive management, difficult equipment maintenance, corrosion, etc., and achieve control accuracy Improvement, simple and practical device, high control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

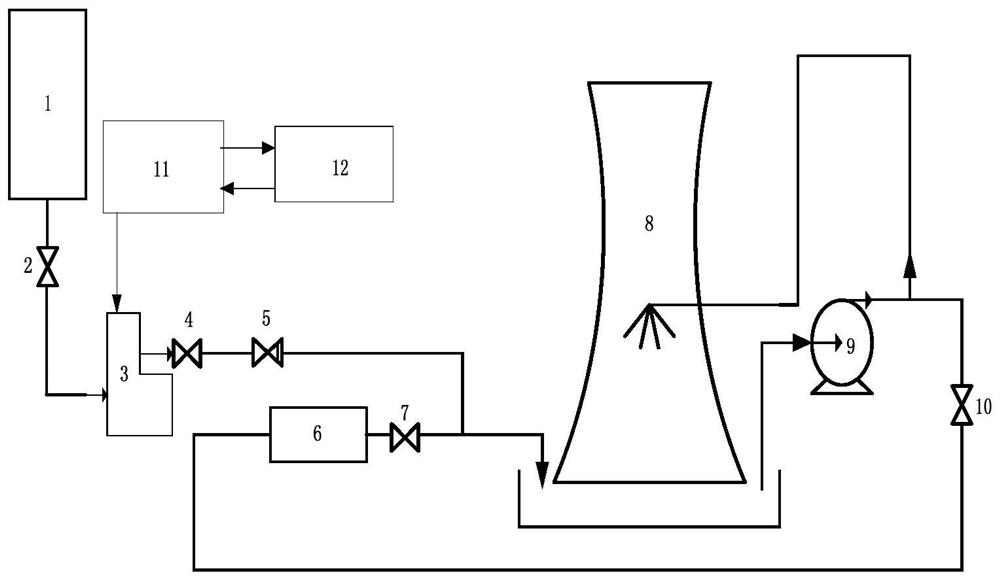

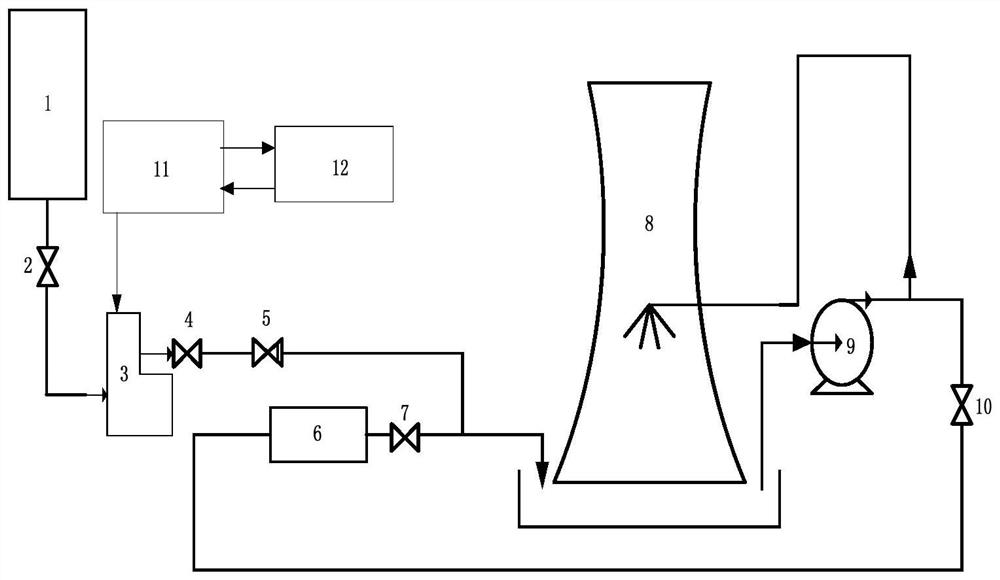

[0041] as attached figure 1 As shown, when putting into operation the automatic control device for industrial circulating water, open the sampling inlet valve 10 and the sampling outlet valve 7, confirm on the touch screen 12 whether the pH sampling value is consistent with the display of the pH online measuring instrument 6, and after confirming that the pH value is consistent, turn on the sampling valve. The acid pump inlet shut-off valve 2 and the acid pump outlet shut-off valve 4 can put the industrial circulating water automatic control device into automatic operation.

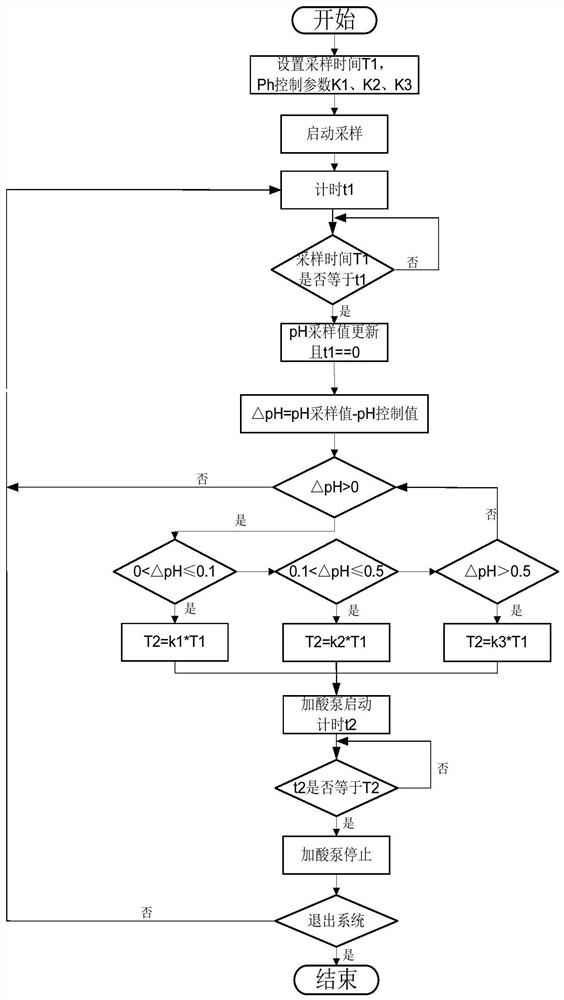

[0042] as attached figure 2 As shown, every sampling period T1, update the pH sampling value, calculate the difference ΔpH between the pH sampling value and the set value, select the control parameters K1, K2, K3 set in the PLC controller according to the value of ΔpH, and calculate If the time T2 required for the acid pump to run in this sampling period is calculated, the acid addition control in this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com