Laser hole partition tipping paper

A tipping paper and laser hole technology, applied in the field of cigarette materials, can solve the problems of inability to filter harmful substances, affect human health and taste, and achieve the effect of increasing taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

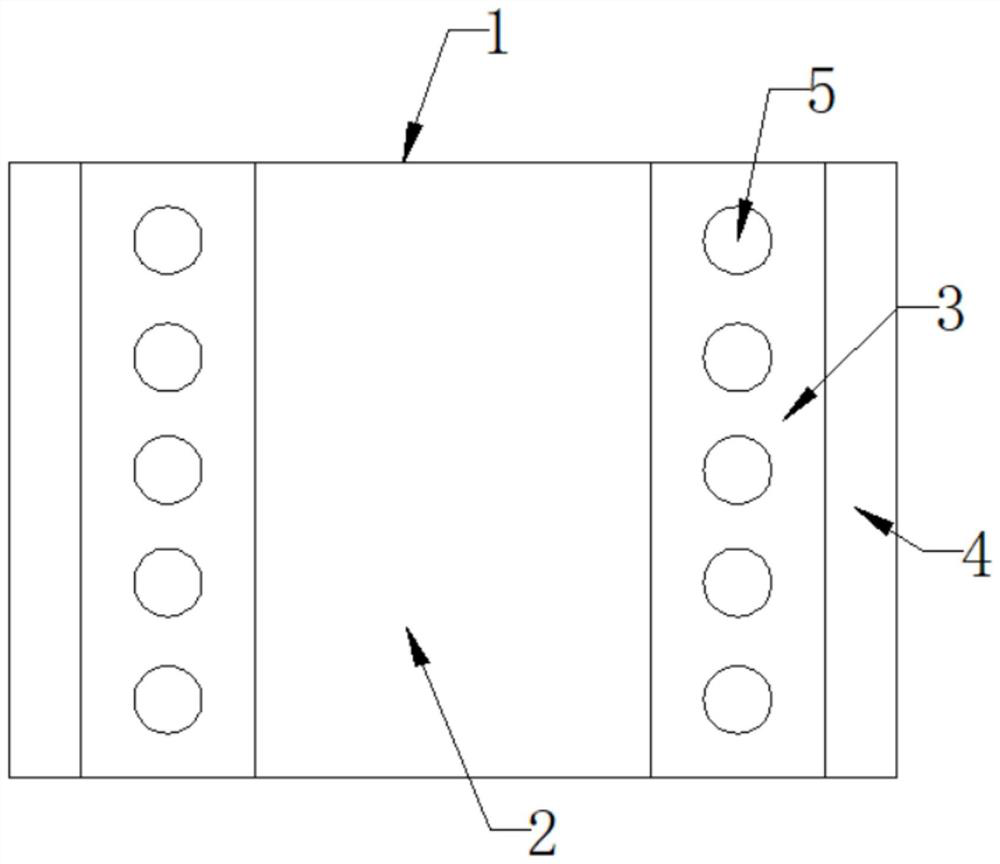

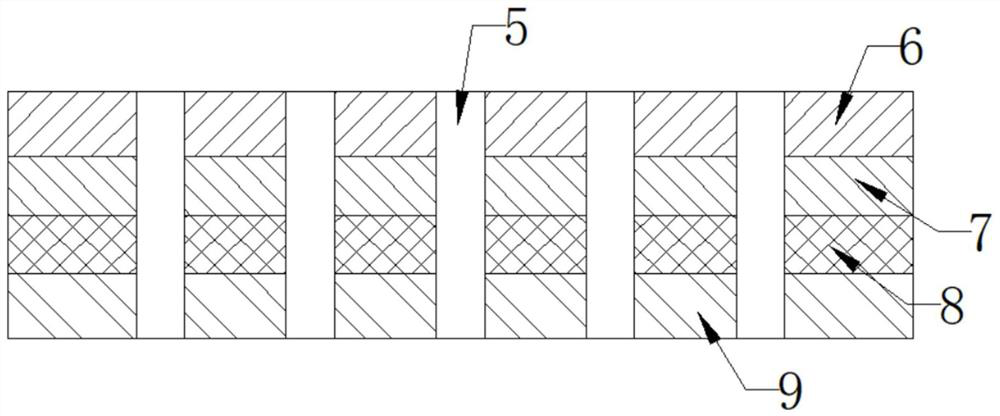

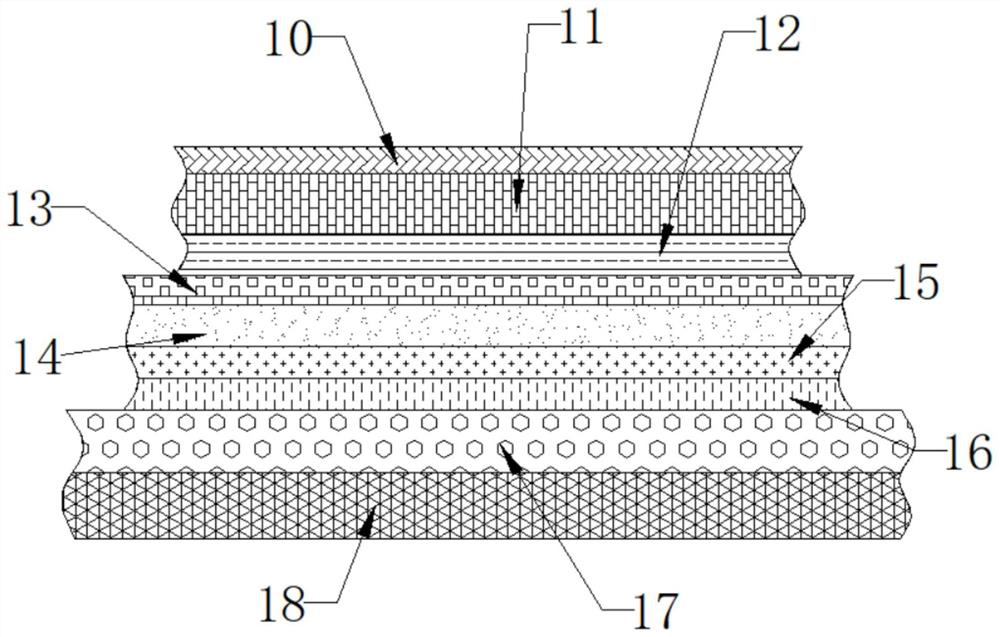

[0021] see Figure 1-4 , the present invention provides a technical solution: a laser hole partition tipping paper, including a tipping paper body 1, the tipping paper body 1 includes a tipping paper layer 2, a release paper layer 3 and an adhesive strip 4, the release paper The paper layer 3 is longitudinally arranged at the two ends of the tipping paper layer 2, and the adjacent ends of the two release paper layers 3 are fixedly connected with the two ends of the tipping paper layer 2, and the two adhesive strips 4 are longitudinally arranged on the two ends of the tipping paper layer. Both ends of the release paper layer 3 and the adjacent ends of the two adhesive strips 4 are fixedly connected to the side walls of the release paper layer 3, and the side walls of the two release paper layers 3 are provided with evenly arranged laser holes 5. The release paper layer 3 includes a release paper 6, a stabilizing film 7, a composite adhesive 8 and an adhesive 9, the stabilizing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com