Heat-preservation comfortable double-layer heated brick bed structure capable of achieving uniform heating

A uniform, double-layer technology, applied in heating methods, household heating, heating systems, etc., can solve the problems of uneven temperature distribution, poor heat preservation performance of the heated kang, and increase the use of fuel, so as to reduce heat loss, Improve thermal insulation performance and save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

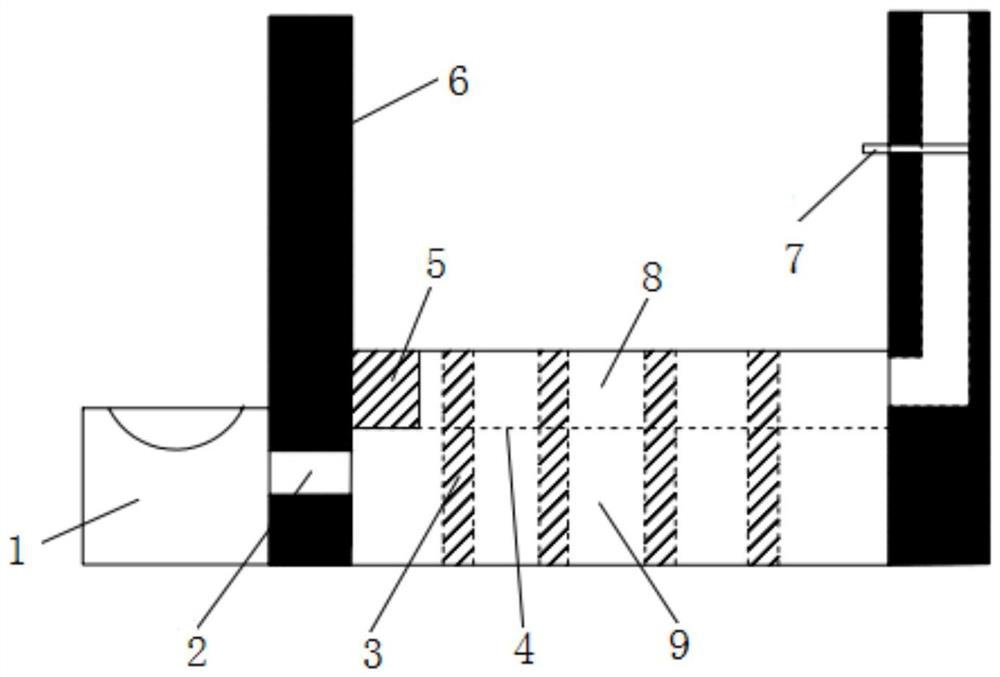

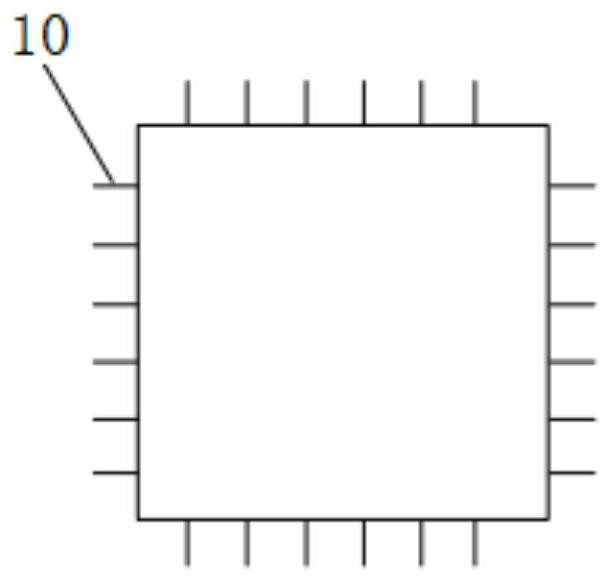

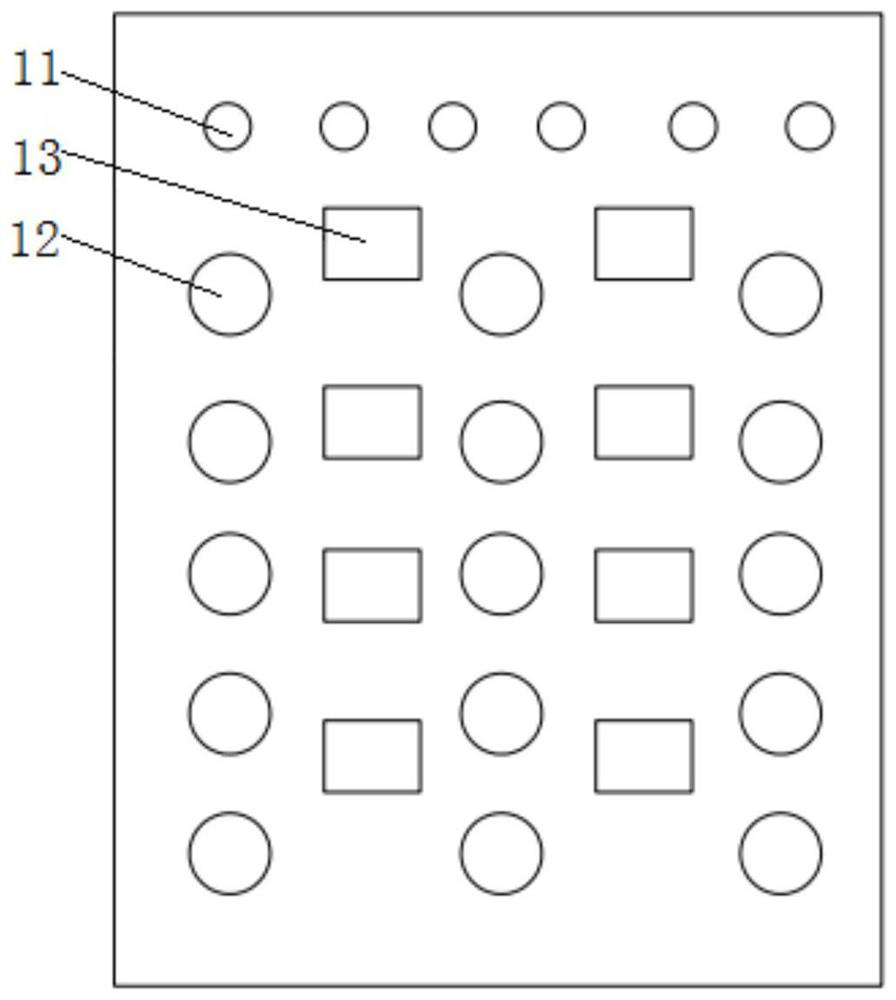

[0020] Such as Figure 1 to Figure 3 Shown, a kind of thermal insulation comfortable double-layer heated kang structure that realizes thermal uniformity comprises a kang board, building body of wall 6 and column 3, and the space surrounded by described building wall 6, ground and kang board is a kang hole, and described A fixed baffle 4 is arranged between the kang board and the ground, and the fixed baffle 4 divides the kang hole into the upper kang hole 8 and the lower kang hole 9 to form double-layer kang holes, so that the smoke does not directly contact the kang board, causing The problem of local overheating. At the same time, the smoke inlet holes on the baffle disperse the smoke to different positions to achieve uniform heat. The upper surface of the fixed baffle 4 is provided with a water storage tank 5, and the water storage tank 5 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com