Wafer chuck for lithography machine

A lithography machine and wafer technology, applied in the field of lithography machines, can solve the problems of complicated operation, difficulty in processing square wafers, inconsistent pattern positions, etc., and achieve the effect of accurate wafer position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

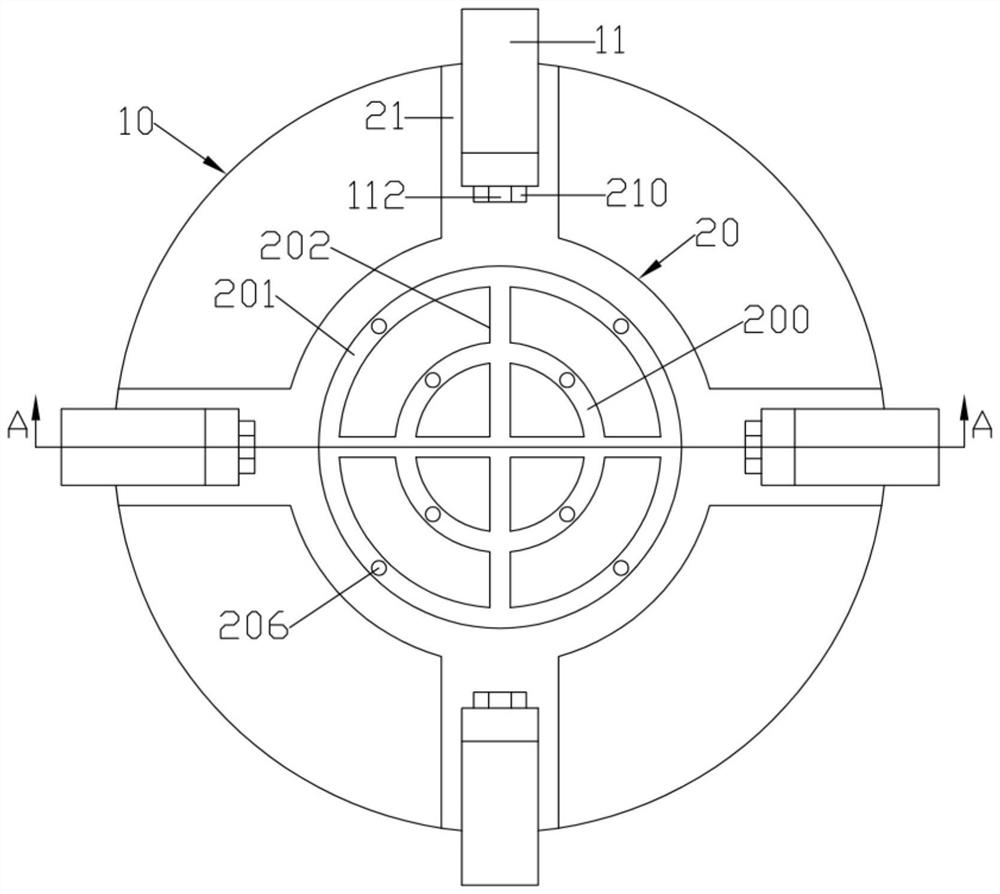

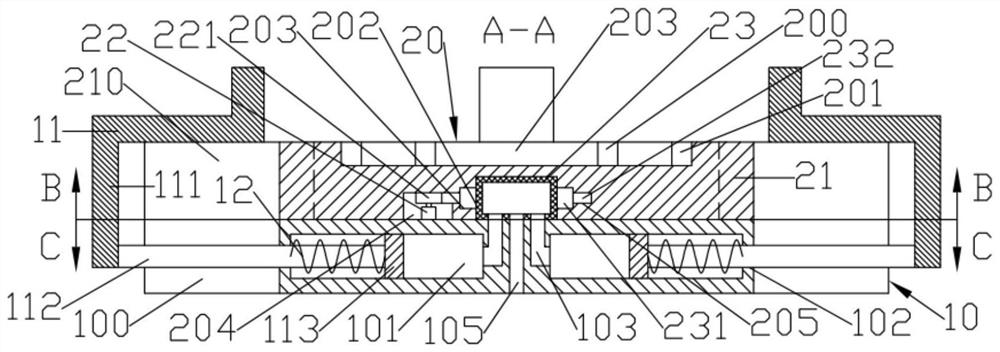

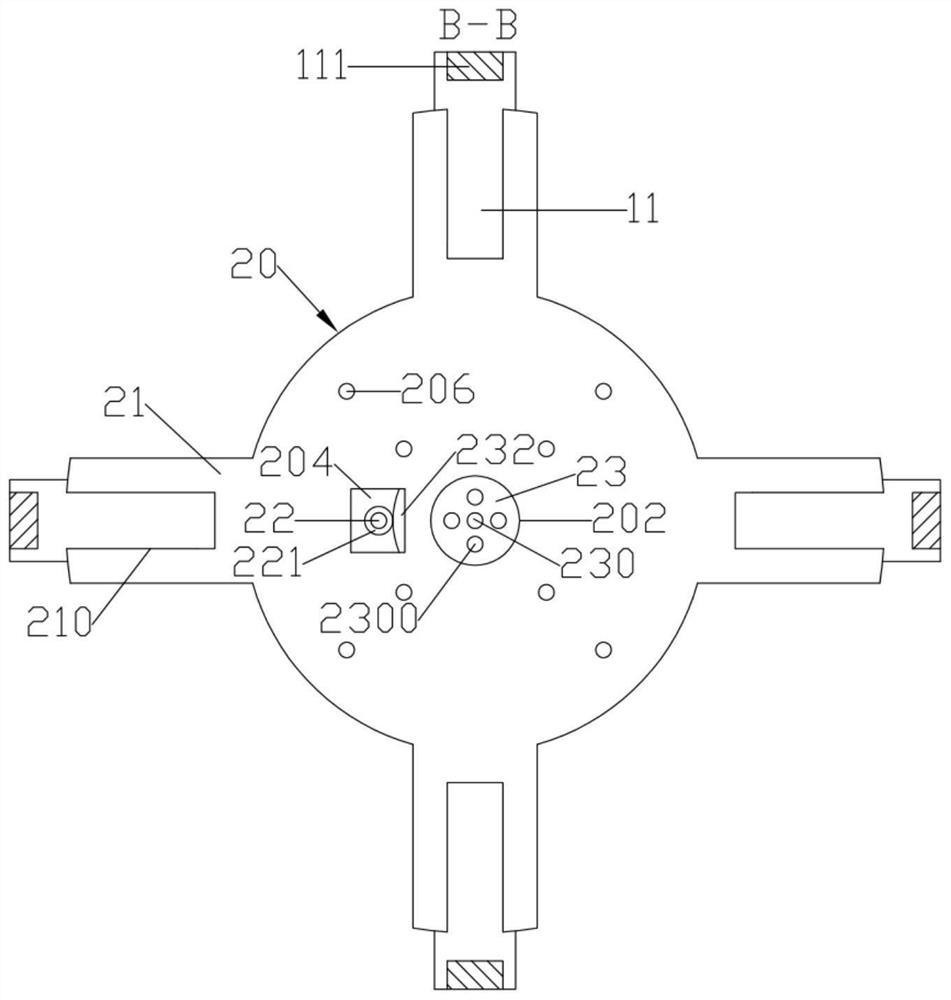

[0019] Such as Figure 1 to Figure 5 Shown, a kind of wafer sucker that is used for lithography machine comprises circular plate-shaped base 10; The upper end surface of base 10 is detachably fixed with circular plate-shaped support platform 20; Both support platform 20 and base 10 The central axis of rotation is set in line; the upper end surface of the support table 20 is formed with a number of coaxial cylindrical groove-shaped adsorption grooves with different diameters; the bottom surface of the adsorption groove is formed with four upper air guide holes 206 that are evenly distributed around the circumference and penetrate up and down; The cylindrical surface of the base 10 is formed with four lower radial moving grooves 100 evenly distributed around the circumference; the center of the lower end surface of the base 10 is formed with an air guide main pipe 105 penetrating up and down; the air guide main pipe 105 is connected to the external suction device; The inside of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com