A processing device for growing gallium nitride epitaxial layer on patterned sapphire substrate

A patterned sapphire and processing device technology, applied to semiconductor devices, electrical components, circuits, etc., can solve the problems of high cost, complex structure, and inability to quickly adjust the temperature conditions for growing gallium nitride epitaxial layers on sapphire substrates. Achieve the effect of low cost, simple structure, convenient and quick adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

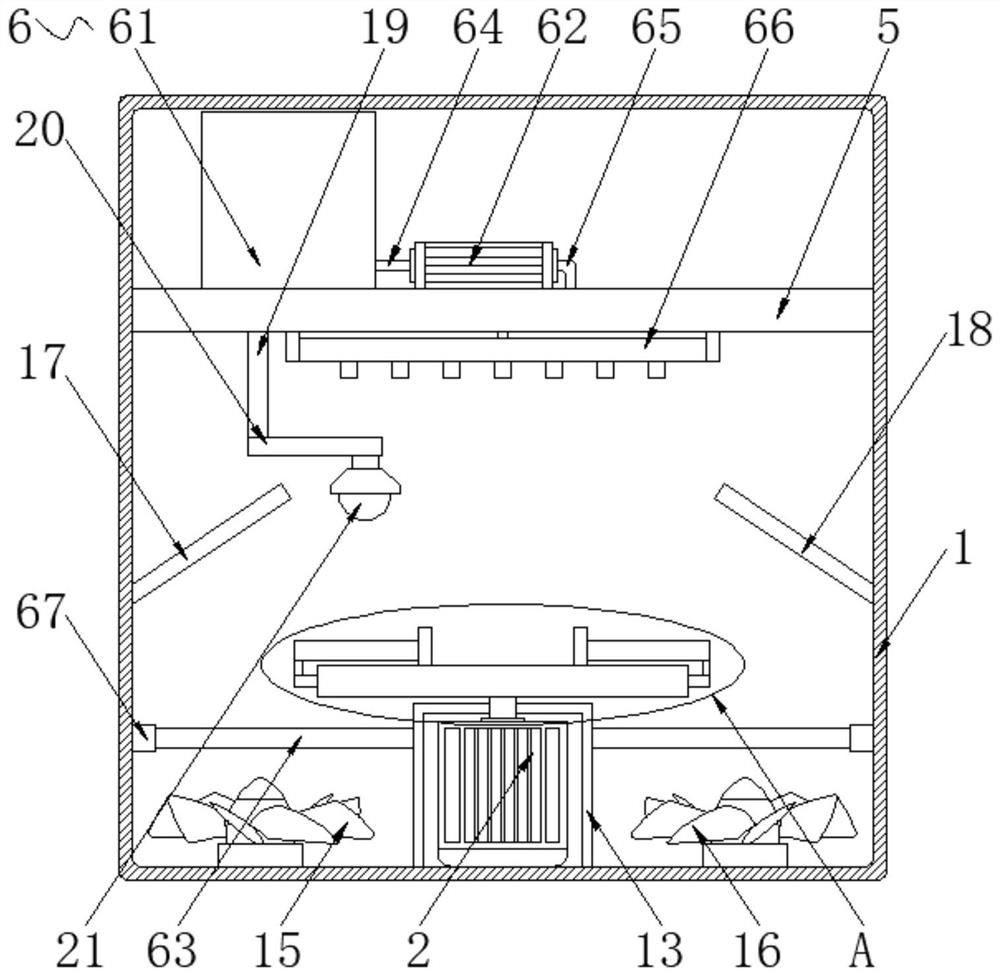

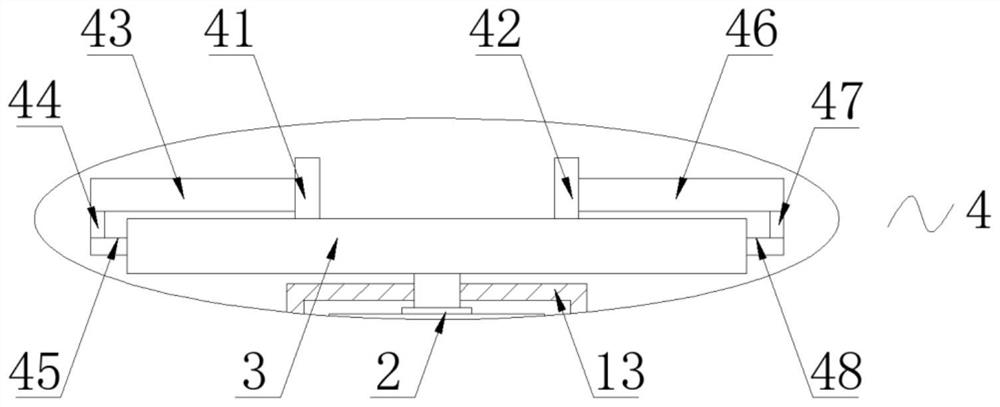

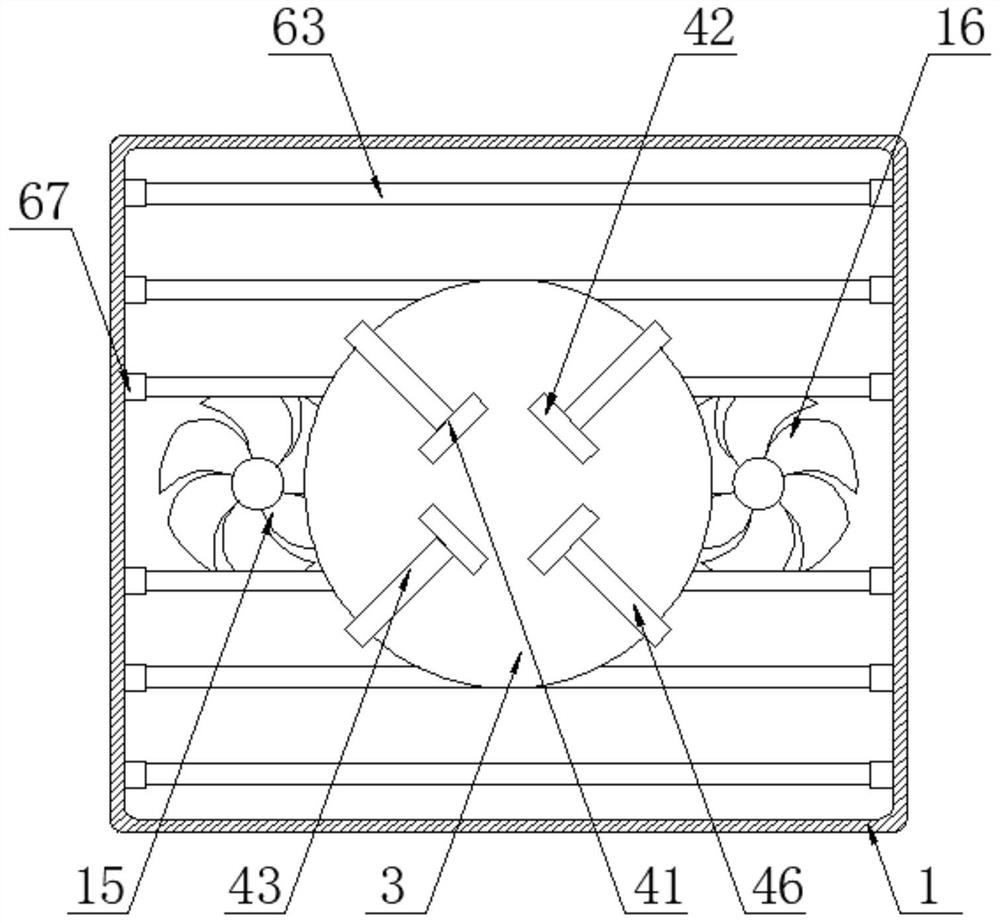

[0032]A processing device for growing a gallium nitride epitaxial layer on a patterned sapphire substrate, comprising a processing box 1, a rotary motor 2 is fixedly connected to the bottom of the inner wall of the processing box 1, and a processing table is fixedly connected to an output end of the rotary motor 2 3. A clamping mechanism 4 is arranged on the processing table 3, a fixing plate 5 is fixedly connected above the inner walls of the processing box 1, and an adjustment mechanism 6 is arranged inside the processing box 1; the adjustment mechanism 6 includes a coolant storage tank 61 , liquid pump 62 and heating pipe 63, the input end of the liquid pump 62 is fixedly connected with an input pipe 64, one end of the input pipe 64 is fixedly connected with one side of the cooling liquid storage tank 61, and the output end of the liquid pump 62 is fixedly connected with an output pipe 65. One end of the output pipe 65 is fixedly connected with a spray head 66, and both ends...

Embodiment 2

[0034] A processing device for growing a gallium nitride epitaxial layer on a patterned sapphire substrate, comprising a processing box 1, a rotary motor 2 is fixedly connected to the bottom of the inner wall of the processing box 1, and a processing table is fixedly connected to an output end of the rotary motor 2 3. A clamping mechanism 4 is arranged on the processing table 3, a fixing plate 5 is fixedly connected above the inner walls of the processing box 1, and an adjustment mechanism 6 is arranged inside the processing box 1; the adjustment mechanism 6 includes a coolant storage tank 61 , liquid pump 62 and heating pipe 63, the input end of the liquid pump 62 is fixedly connected with an input pipe 64, one end of the input pipe 64 is fixedly connected with one side of the cooling liquid storage tank 61, and the output end of the liquid pump 62 is fixedly connected with an output pipe 65. One end of the output pipe 65 is fixedly connected with a spray head 66, and both end...

Embodiment 3

[0036] A processing device for growing a gallium nitride epitaxial layer on a patterned sapphire substrate, comprising a processing box 1, a rotary motor 2 is fixedly connected to the bottom of the inner wall of the processing box 1, and a processing table is fixedly connected to an output end of the rotary motor 2 3. A clamping mechanism 4 is arranged on the processing table 3, a fixing plate 5 is fixedly connected above the inner walls of the processing box 1, and an adjustment mechanism 6 is arranged inside the processing box 1; the adjustment mechanism 6 includes a coolant storage tank 61 , liquid pump 62 and heating pipe 63, the input end of the liquid pump 62 is fixedly connected with an input pipe 64, one end of the input pipe 64 is fixedly connected with one side of the cooling liquid storage tank 61, and the output end of the liquid pump 62 is fixedly connected with an output pipe 65. One end of the output pipe 65 is fixedly connected with a spray head 66, and both end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com