Rotary cultivation device

A cultivation device and rotary technology, which is applied in the field of rotary cultivation devices, can solve the problems of uneven light receiving, limited space for cultivation, and uneven light receiving for cultivated plants, so as to protect young crops, increase space utilization, and improve water quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

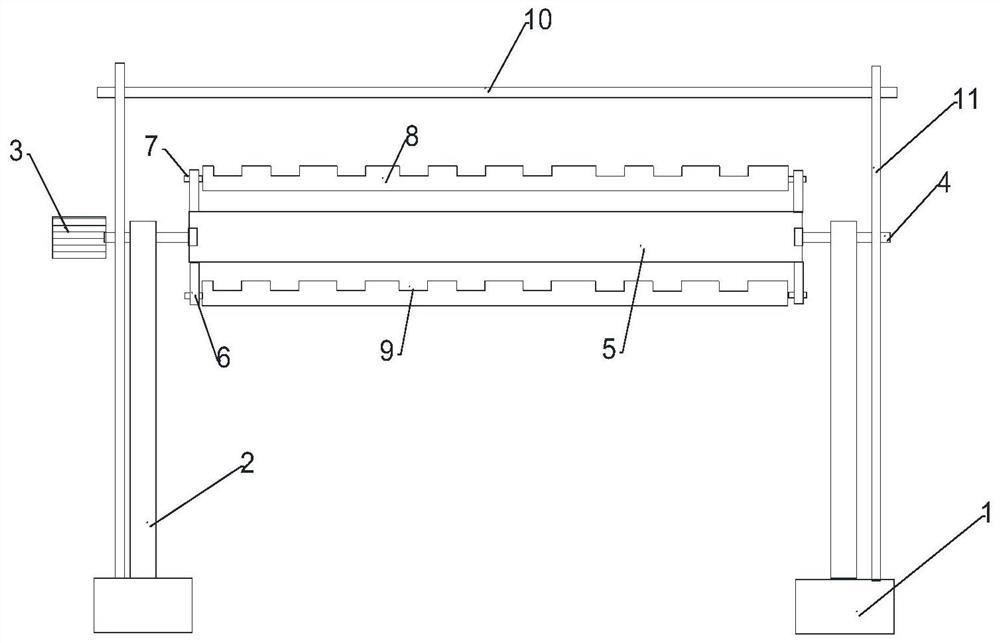

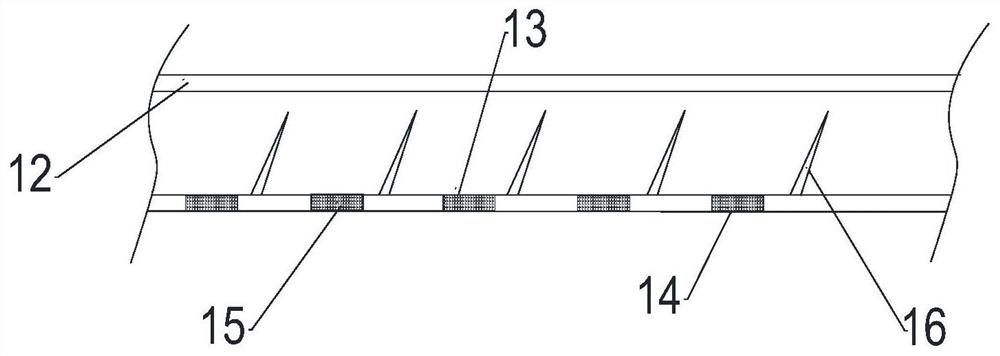

[0024] The rotary cultivation device includes a cultivation base 1, a cultivation support 2, a cultivation turntable and a cultivation pipe groove,

[0025] The cultivation support 2 is integrally arranged on the cultivation base 1, and a placement groove is provided on the top of the cultivation support 2. The cultivation turntable includes a driving motor 3, a turntable shaft 4, a turntable 5 and a turntable arm 6, and the turntables are respectively fixed at both ends of the turntable 5. The shaft 4 and the turntable shaft 4 are placed in the placement groove, and the drive motor 3 is arranged outside the turntable shaft 4. The output shaft of the drive motor 3 is connected with the turntable shaft 4, and the turntable arm 6 is arranged symmetrically at both ends of the turntable 5. The arm 6 is provided with a mounting hole, and the cultivation pipe groove is installed on the turntable arm 6 through the mounting hole, and the driving motor 3 adopts a model of GB37-520 minia...

Embodiment 2

[0030] The rotary cultivation device includes a cultivation base 1, a cultivation support 2, a cultivation turntable and a cultivation pipe groove,

[0031] The cultivation support 2 is integrally arranged on the cultivation base 1, and a placement groove is provided on the top of the cultivation support 2. The cultivation turntable includes a driving motor 3, a turntable shaft 4, a turntable 5 and a turntable arm 6, and the turntables are respectively fixed at both ends of the turntable 5. The shaft 4 and the turntable shaft 4 are placed in the placement groove, and the drive motor 3 is arranged outside the turntable shaft 4. The output shaft of the drive motor 3 is connected with the turntable shaft 4, and the turntable arm 6 is arranged symmetrically at both ends of the turntable 5. The arm 6 is provided with a mounting hole, and the cultivation pipe groove is installed on the turntable arm 6 through the mounting hole, and the driving motor 3 adopts a model of GB37-520 minia...

Embodiment 3

[0041] The rotary cultivation device includes a cultivation base 1, a cultivation support 2, a cultivation turntable and a cultivation pipe groove,

[0042] The cultivation support 2 is integrally arranged on the cultivation base 1, and a placement groove is provided on the top of the cultivation support 2. The cultivation turntable includes a driving motor 3, a turntable shaft 4, a turntable 5 and a turntable arm 6, and the turntables are respectively fixed at both ends of the turntable 5. The shaft 4 and the turntable shaft 4 are placed in the placement groove, and the drive motor 3 is arranged outside the turntable shaft 4. The output shaft of the drive motor 3 is connected with the turntable shaft 4, and the turntable arm 6 is arranged symmetrically at both ends of the turntable 5. The arm 6 is provided with a mounting hole, and the cultivation pipe groove is installed on the turntable arm 6 through the mounting hole, and the driving motor 3 adopts a model of GB37-520 minia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com