Drilling equipment for PCB production

A technology of PCB board and drilling equipment, applied in metal processing and other directions, can solve the problems of operator's personal safety threat, affecting processing efficiency, poor processing continuity, etc., to save waiting time, shorten processing cycle, and ensure the effect of yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The content of the present invention will be described below in conjunction with specific embodiments.

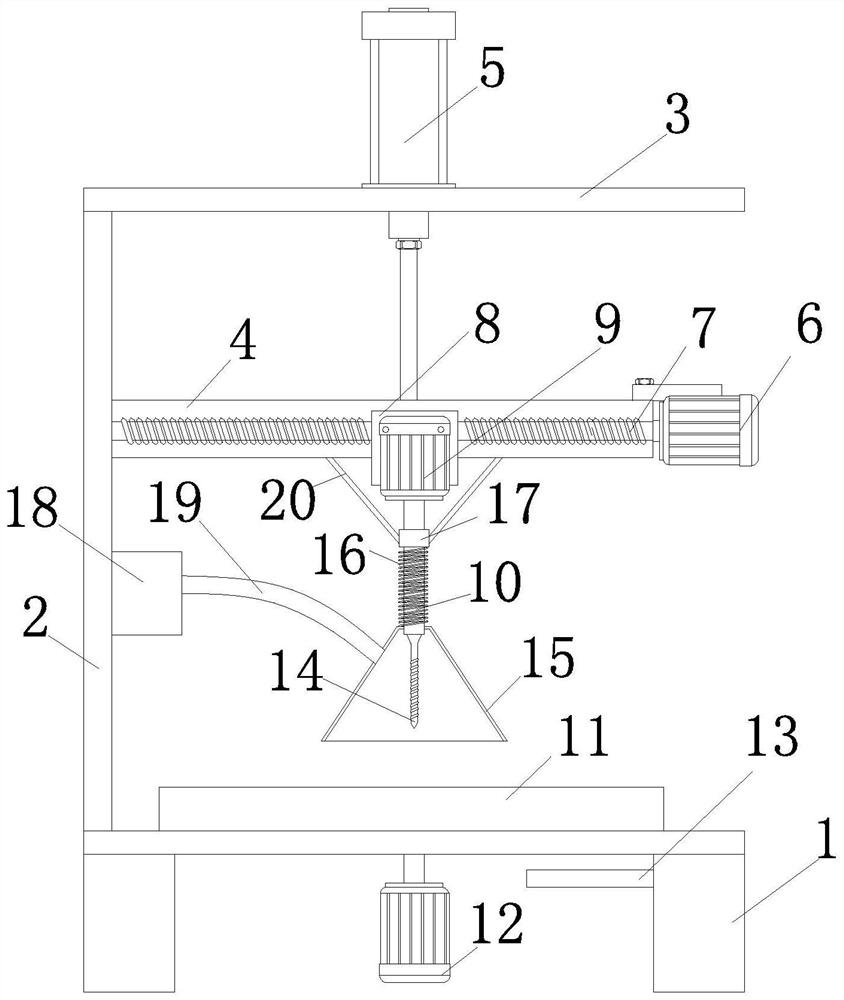

[0020] refer to figure 1 , a PCB board drilling device proposed by the present invention includes a base 1 and a bracket connected to the base 1, a rotary feeding unit is installed on the base 1, and a drilling unit is installed on the bracket. The drilling unit includes a drill bit 10 , and the rotary feeding unit is used to transport the PCB board directly under the drill bit 10 .

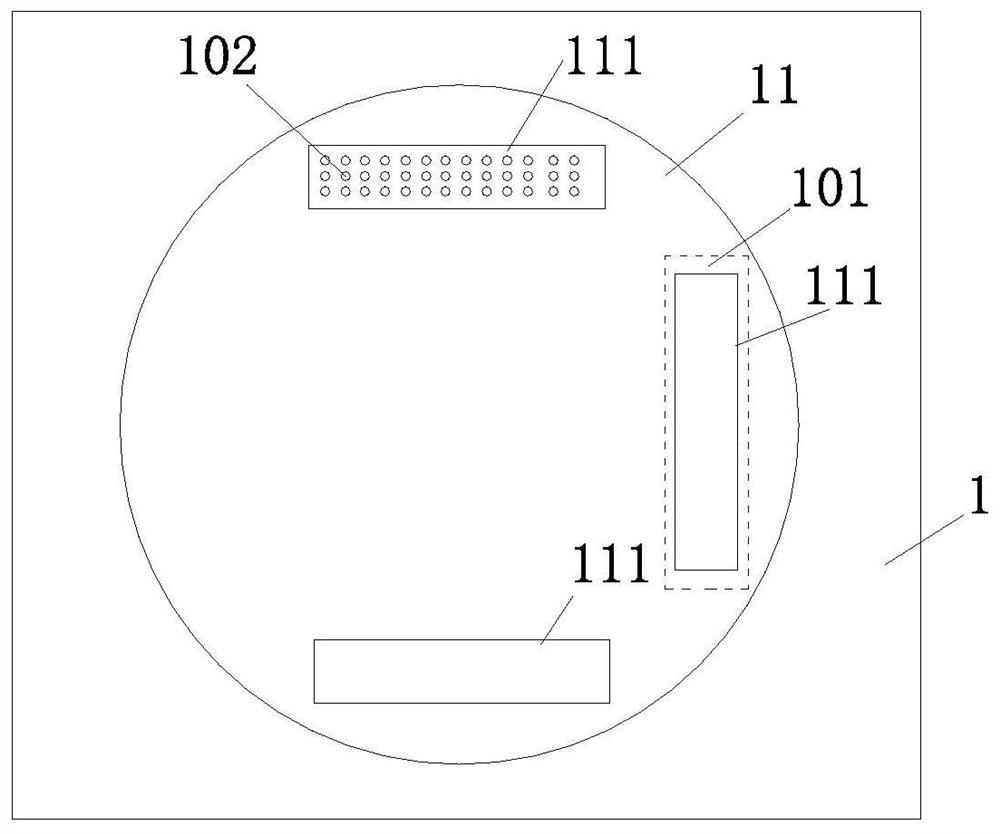

[0021] The rotary material unit includes a rotary table 11 rotatably connected to the base 1, the rotary table 11 is supported by the base 1, a shaft hole is opened through the base 1, and the bottom of the base 1 is installed with The third motor 12 , the output shaft of the third motor 12 is fixedly connected to the turntable 11 through the shaft hole, and the output shaft of the third motor 12 is arranged coaxially with the turntable 11 . refer to figure 2 At least three limiting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com