Granulation device for biodegradable film

A technology of biodegradable film and granulation device, applied in the direction of coating, etc., can solve the problems of insufficient cooling of raw materials, and achieve the effect of preventing accidents, good effect and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

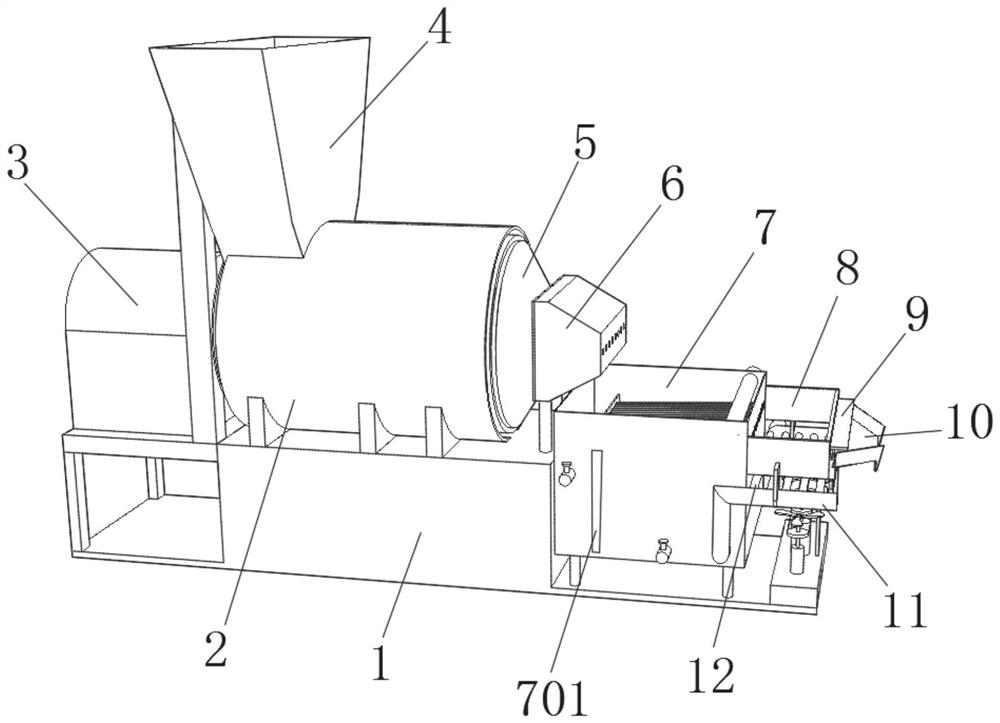

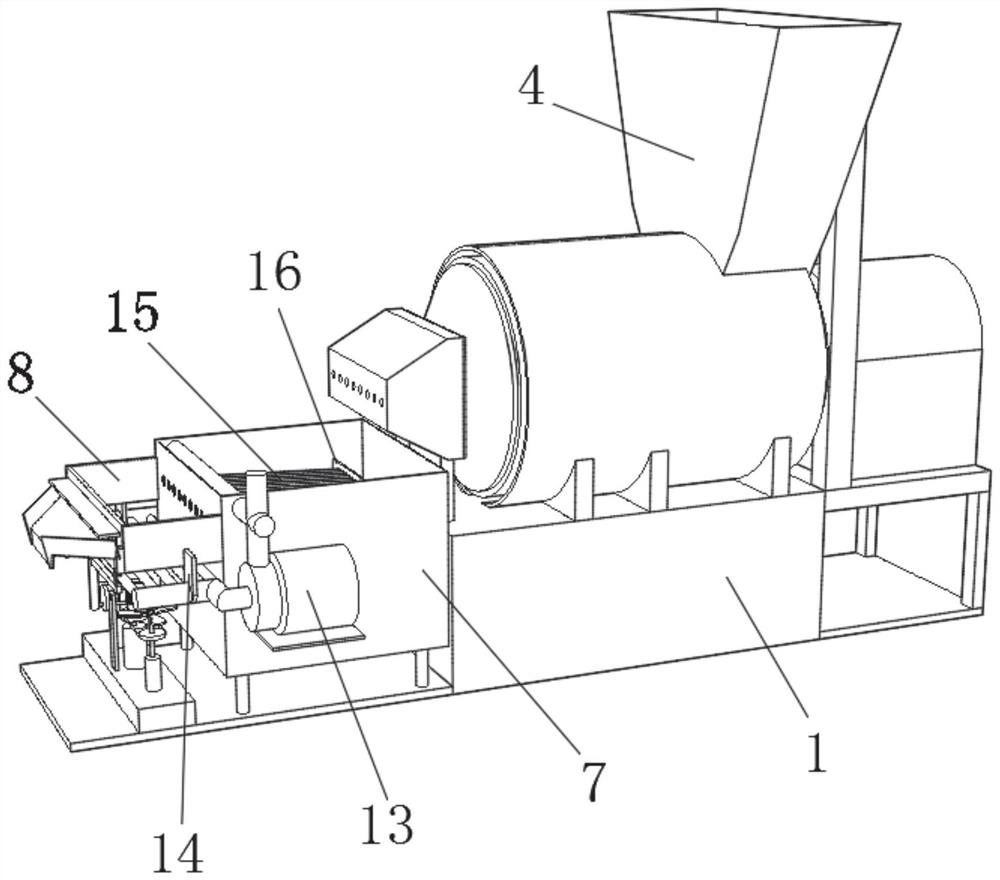

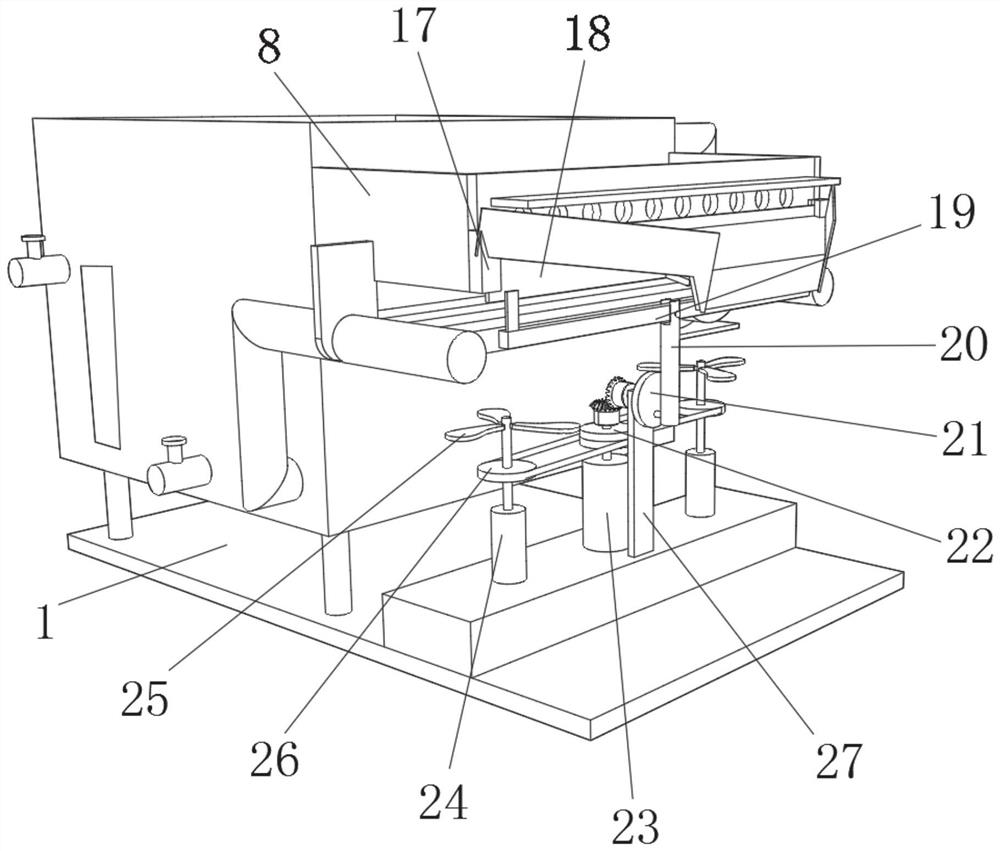

[0031] refer to Figure 1-Figure 4 , a granulation device for biodegradable film, comprising a frame 1, the upper surface of the frame 1 is fixed with a water tank 7 by bolts, and the inner wall of one side of the water tank 7 is fixed with a sloping plate 16 by bolts, and the sloping plate 16 can change the water flow Direction, so that the temperature of the water on the side close to the raw material just extruded is higher, avoiding the impact on the quality of the product due to the sudden drop in the temperature of the raw material just extruded, a water outlet is provided outside the side of the water tank 7, and a water outlet of the water outlet One side of the first main water pipe 11 is fixed with bolts, and one side of the first main water pipe 11 is provided with an installation hole, one side of the installation hole is fixed with a water distribution pipe 12 through bolts, and the other outer wall of the water tank 7 is fixed with a water pump 13 through bolts T...

Embodiment 2

[0035] refer to Figure 5-Figure 6 , a granulation device for biodegradable film, the outer wall of the bottom of the receiving hopper 10 is fixed with a bracket 32 by bolts, one side of the bracket 32 is provided with a mounting groove, and a crowbar 35 is rotated and connected in the mounting groove, and one end of the crowbar 35 passes through Bolt is fixed with tension spring 33, and tension spring 33 can reset crowbar 35 after crowbar 35 rotates, and the other end of tension spring 33 is fixed with the bottom outer wall of hopper 10, and the other end of crowbar 35 is provided with jack , a sliding rod 37 is movably connected in the socket, and one end of the sliding rod 37 is fixed with a hammer head 31 through a bolt, and the hammer head 31 can knock on the hopper, reducing the workload of the operator, and the other end of the sliding rod 37 is sleeved There is a spring 36, which can reset the slide bar 37 after the slide bar 37 is displaced, and one side of the cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com