Outer wall full-shearing structure and construction process thereof

A construction technology and exterior wall technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of high rigidity of exterior walls, endangering building safety, wall cracking, etc., achieving good integrity, improving seismic performance, Avoid wall effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

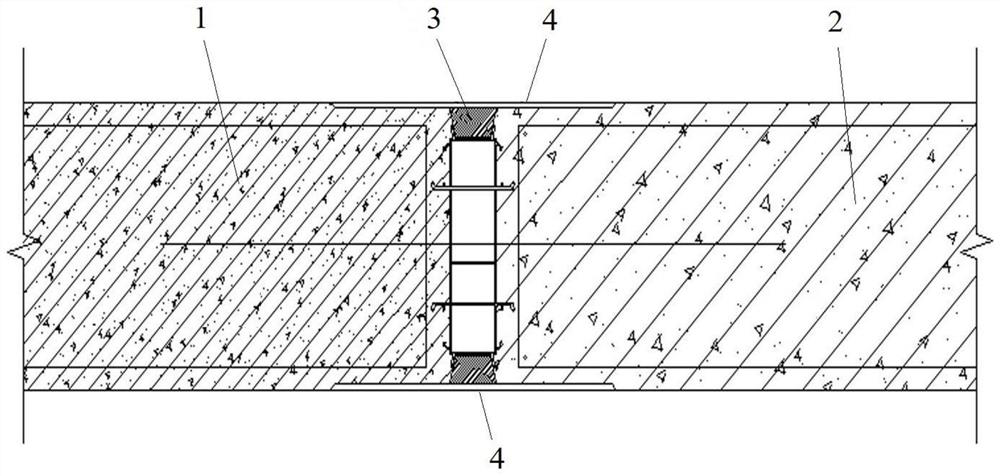

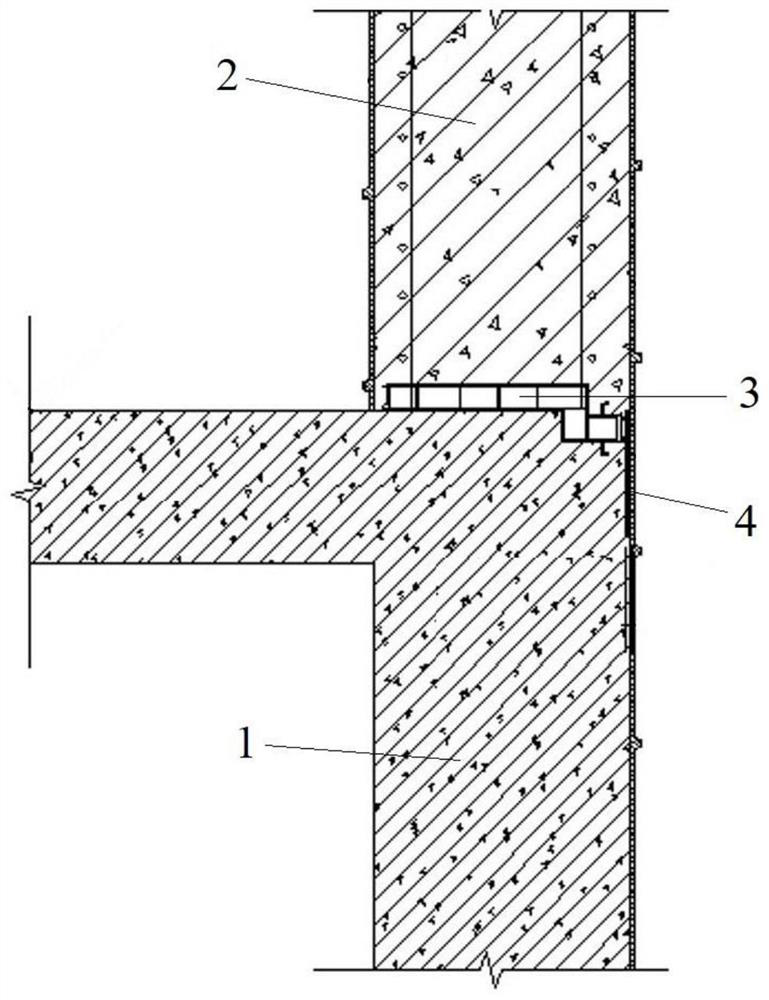

[0042] Such as Figure 1 to Figure 2 As shown, a kind of exterior wall full-shear structure described in the present invention includes a structural wall 1 and a load-bearing wall 2, and the load-bearing wall 2 and the structural wall 1 are connected by a pull joint structure, and the structural wall 1 and the The load-bearing walls 2 are reinforced concrete cast-in-place structures, and the seam structure is used to separate the cast-in-place structural walls 1 from the load-bearing walls 2 .

[0043] Specifically, the seam structure includes a partition plate 3 arranged between the load-bearing wall 2 and the structural wall 1, and anchoring steel bars pass through the partition plate 3 and are inserted into the load-bearing wall 2 and the structural wall 1 respectively. , the partition board 3 is a plastic board, the plastic board includes two oppositely arranged panels, and several ribs are arranged at intervals between the panels, so that the plastic board has a spatial s...

Embodiment 2

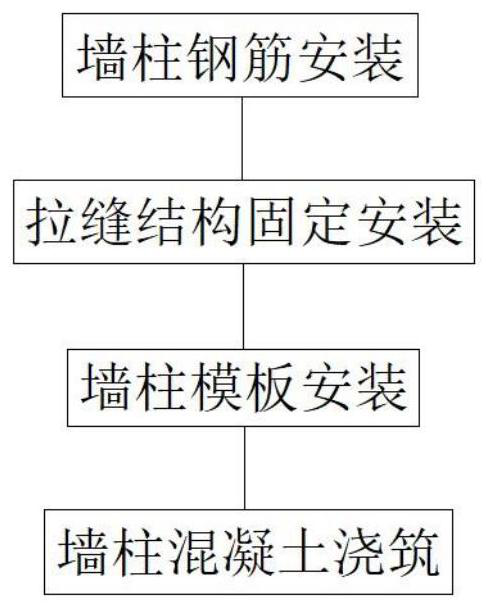

[0047] Such as Figure 1 to Figure 3 As shown, a kind of construction technology of the above-mentioned outer wall full shear structure of the present invention comprises the following steps:

[0048] The reinforcement of the structural wall 1 and the load-bearing wall 2 is installed;

[0049] The drawing seam structure between the structural wall 1 and the bearing wall 2 is fixedly installed;

[0050] Formwork installation of the structural wall 1 and the load-bearing wall 2;

[0051] Concreting of the construction wall 1 and the bearing wall 2 .

[0052] Wherein, for the vertical seam structure between the structural wall 1 and the load-bearing wall 2, double-sided adhesive tape is pasted in the outer groove of the seam structure before installation to prevent the concrete from filling the groove after pouring is completed. The groove cannot be glued later (the groove in the room does not need to do this process), the wall column reinforcement is installed, the vertical s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com