Pig farm temperature and humidity automatic adjusting system applying ground source heat pump technology

A ground source heat pump and automatic adjustment technology, applied in the field of livestock and poultry breeding facilities, can solve the problem of not being able to provide a suitable temperature and humidity environment, and achieve the effect of improving operation reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

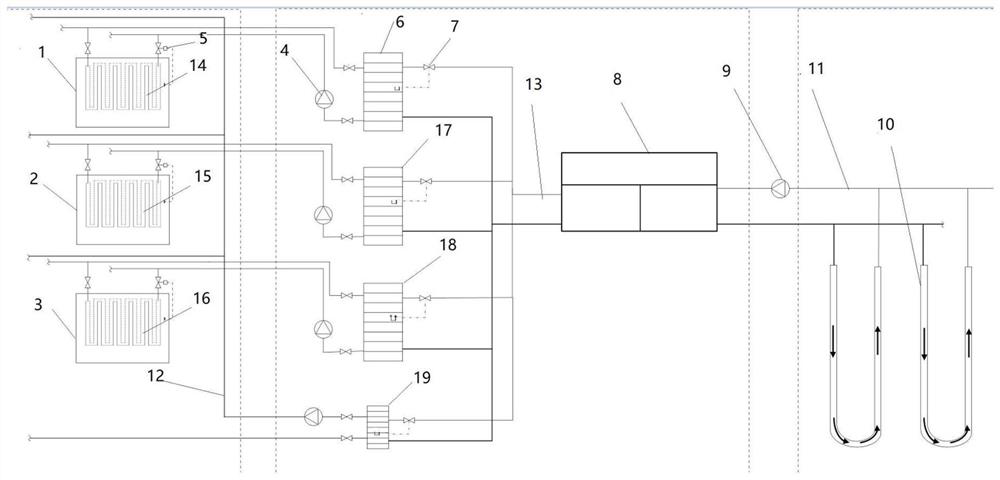

[0034] like figure 1 As shown, the piggery area in this embodiment includes piglet area 1 at the birth stage, piglet area 2 at the weaning stage, and piglet area 3 at the weaning stage. , you can set more than one. This embodiment provides a pig farm temperature and humidity automatic adjustment system using ground source heat pump technology, including: a heat pump unit 8 and a U-shaped buried heat exchange tube 10, the input end of the buried heat exchange tube 10 and the heat pump unit 8 Through the first circulation pipeline 11, the circulation refrigerant pipeline 13 of the heat pump unit 8 is respectively used to communicate with the second circulation pipeline 14 of the newborn stage piglet area 1, the third circulation pipeline 15 and the third circulation pipeline 15 of the weaning stage piglet area 2. The fourth circulation pipeline 15 in the fattening pig area 3 performs heat exchange.

[0035] This application provides an automatic temperature and humidity adjust...

Embodiment 2

[0041] like figure 1 As shown, the piggery area in this embodiment includes piglet area 1 at the birth stage, piglet area 2 at the weaning stage, and piglet area 3 at the weaning stage. , you can set more than one. This embodiment provides a pig farm temperature and humidity automatic adjustment system using ground source heat pump technology, including: a heat pump unit 8 and a U-shaped buried heat exchange tube 10, the input end of the buried heat exchange tube 10 and the heat pump unit 8 Through the first circulation pipeline 11, the circulation refrigerant pipeline 13 of the heat pump unit 8 is respectively used to communicate with the second circulation pipeline 14 of the newborn stage piglet area 1, the third circulation pipeline 15 and the third circulation pipeline 15 of the weaning stage piglet area 2. The fourth circulation pipeline 15 in the fattening pig area 3 performs heat exchange.

[0042] This application provides an automatic temperature and humidity adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com