Full-automatic wine bottle cleaning machine

A washing machine, fully automatic technology, applied in the field of machinery, can solve the problems of not conforming to the concept of energy saving, time-consuming cleaning work, knocking of wine bottles, etc., to achieve the effect of easy replacement, high cleaning efficiency, and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

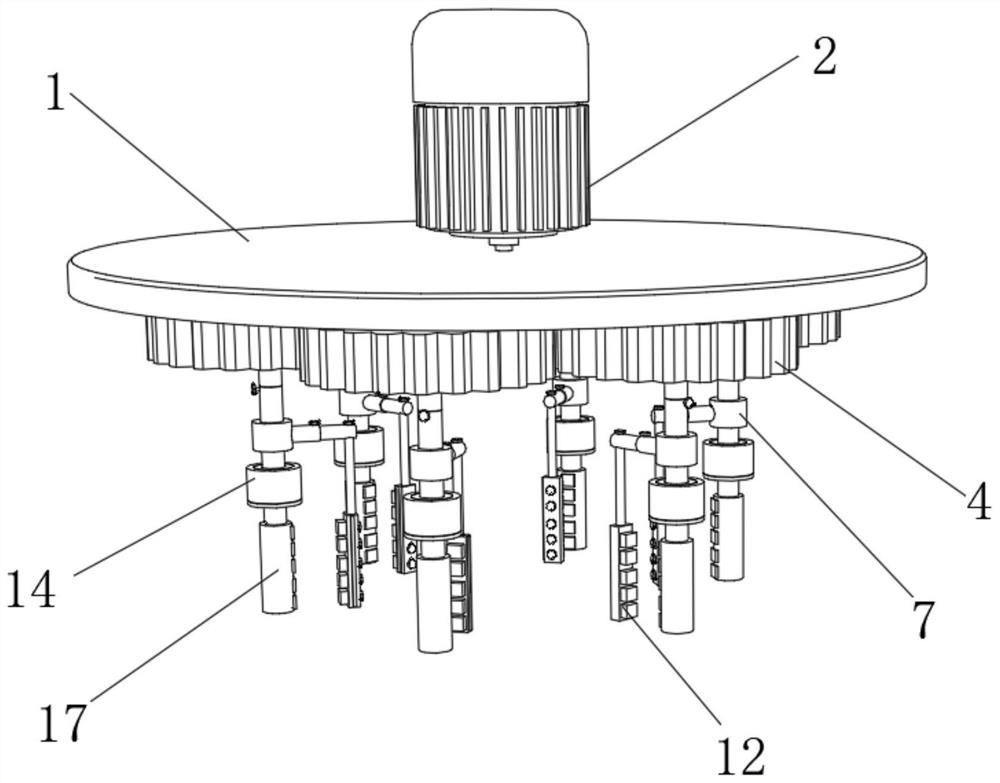

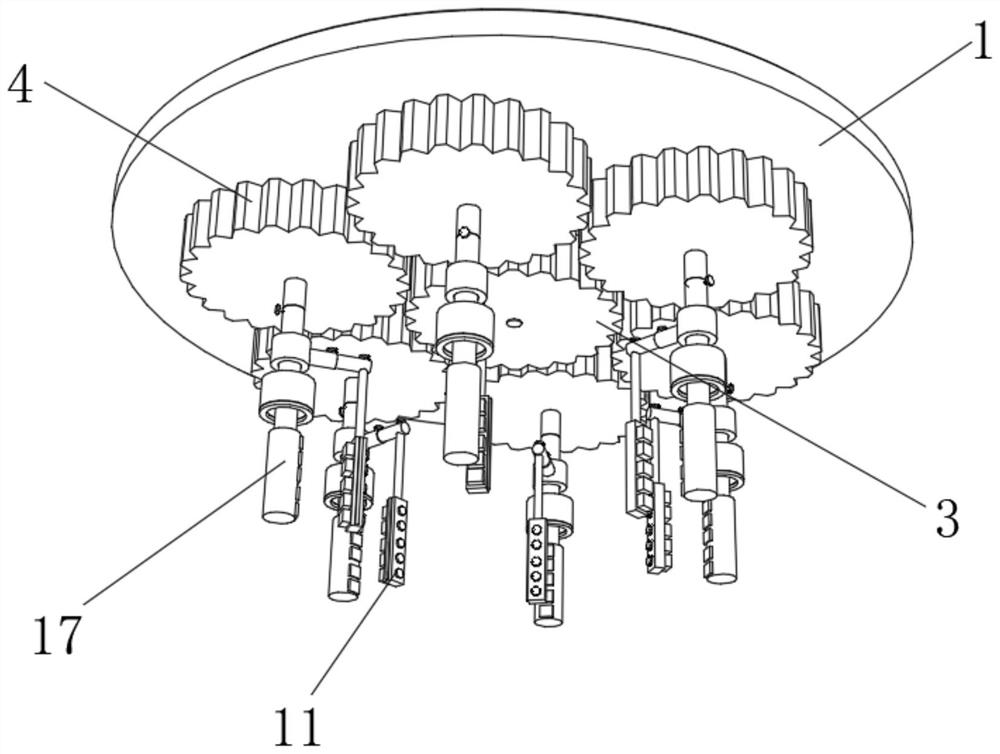

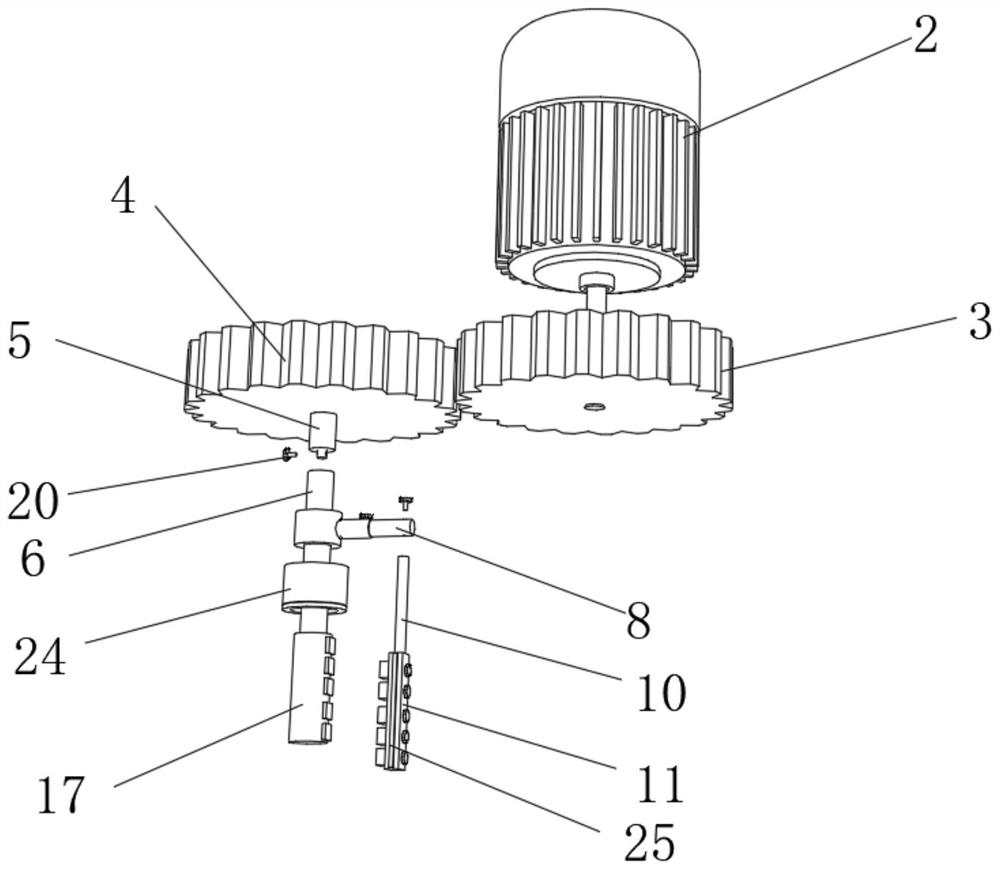

[0029] refer to Figure 1-4 , a full-automatic wine bottle cleaning machine, comprising a support platform 1, a motor 2 is fixedly connected to the center of the upper end of the support platform 1, the output shaft of the motor 2 runs through the support platform 1 and is fixedly connected to a driving gear 3, and the lower end of the support platform 1 is rotatably connected There are a plurality of driven gears 4 meshing with the driving gear 3, and the plurality of driven gears 4 are distributed around the center of the support platform 1. The lower ends of the driven gears 4 are fixedly connected with fixed shafts, and the fixed sleeves on the fixed shafts Connected with a fixed ring 7, the side end of the fixed ring 7 is connected with a support rod 10 through a connecting key, the lower end of the support rod 10 is welded with an outer pile head 11, and the end of the outer pile head 11 close to the fixed shaft is fixedly connected with a first cleaning block 12, The lo...

Embodiment 2

[0039] refer to image 3 , a fully automatic wine bottle cleaning machine, compared with Embodiment 1 in this embodiment, the side end of the outer pile head 11 is fixedly connected with a crack sensor 25 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com