Milling tool for conical thin-walled part

A thin-walled parts, milling technology, applied in metal processing equipment, metal processing mechanical parts, positioning devices, etc., can solve the problems of excessive wall thickness, roundness, uneven wall thickness, etc., to reduce the cost of tooling manufacturing , The effect of low manufacturing precision requirement and remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

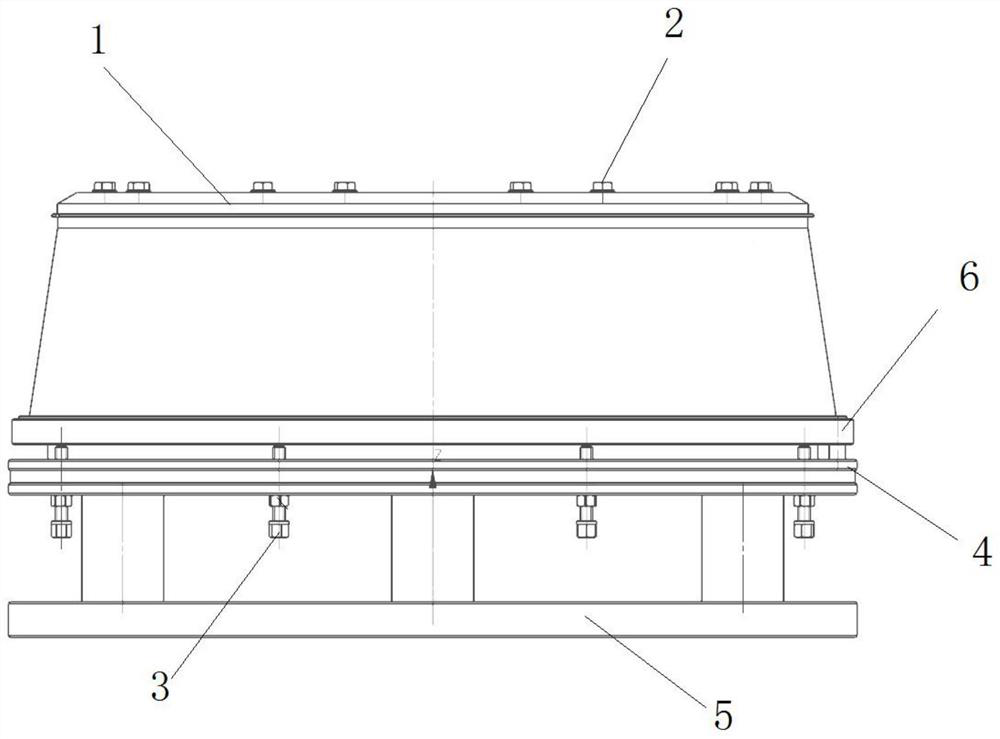

[0020] combined with figure 1 The notations describe the invention in detail.

[0021] (1) Remove gland 1: put figure 1 The upper hold down bolt 2 is shown with the gland removed.

[0022] (2) Adjust the bottom support: set figure 1 The shown bottom adjustable bolt 3 is rotated counterclockwise for adjustment, driving the bottom support ring 6 to move down until the bottom support ring contacts the base of the fixture 5 and stops.

[0023] (3) Align the base: place the fixture on the center of the machine table, and align in the circumferential direction figure 1 The shown fixture aligning belt 4 compresses the fixture base and the workbench surface.

[0024] (4) Clamping parts: press the parts figure 1 The orientation shown is set on the matching tapered surface of the fixture body.

[0025] (5) Circumferential adjustment: adjust the circumferential position of the part to align with the machining angle.

[0026] (6) Assembly gland: put figure 1 The gland shown is pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com