Film blowing containing method

A technology of film blowing machine and film, which is applied in the field of blown film containment, can solve problems such as POE precipitation, and achieve the effects of increasing elongation at break, reducing loss, and increasing elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Specific embodiments of the present invention will be described in detail below. In order to avoid too many unnecessary details, well-known structures or functions will not be described in detail in the following embodiments. Approximate language used in the following examples is for quantitative representations, indicating that certain variations in quantities are permissible without altering essential function. Unless defined otherwise, technical and scientific terms used in the following examples have the same meaning as commonly understood by one of ordinary skill in the art to which this invention belongs.

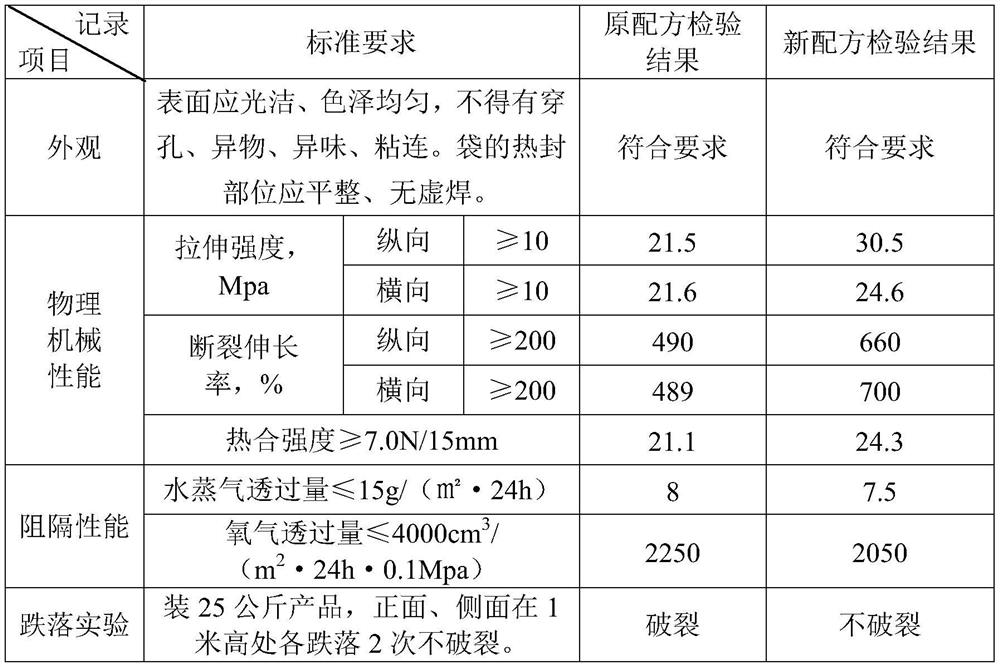

[0016] A blown film containment method that isolates the POE in the middle layer.

[0017] Among them, the formula of the three-layer raw material is as follows:

[0018] Inner layer: A(LDPE):B(LLDPE)=3:7

[0019] Middle layer: A(LDPE):POE:B(LLDPE)=3:4:3

[0020] Outer layer: A(LDPE):B(LLDPE)=3:7.

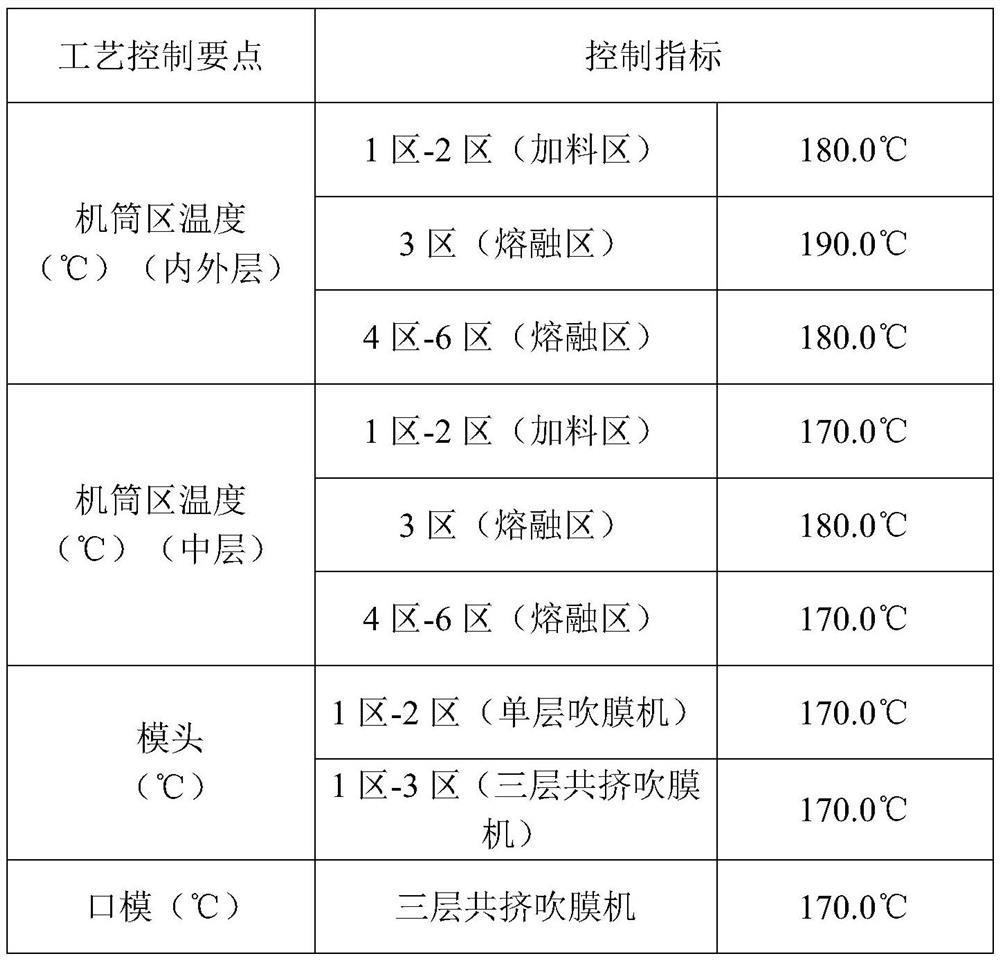

[0021] Blown film temperature parameters are shown in Tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com