Crushing type micro-power sewage treatment equipment

A sewage treatment equipment, micro-power technology, applied in water/sewage treatment equipment, water/sewage treatment, water/sewage multi-stage treatment, etc. problems, to achieve the effect of improving the decomposition rate, facilitating the quantitative placement of pharmaceuticals, and improving the crushing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

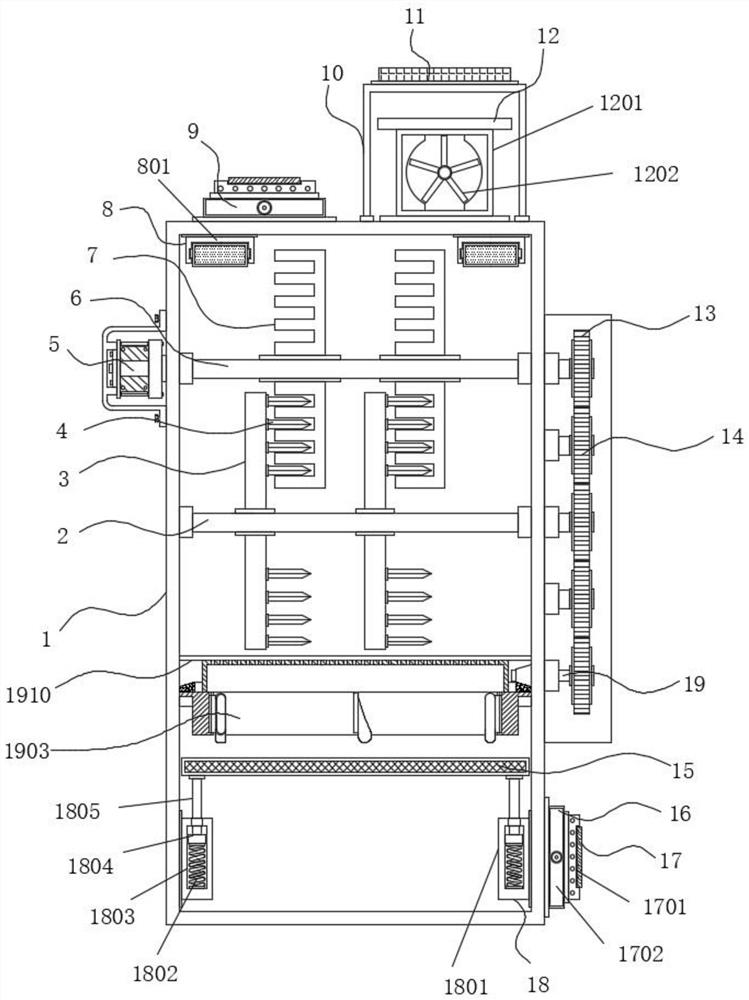

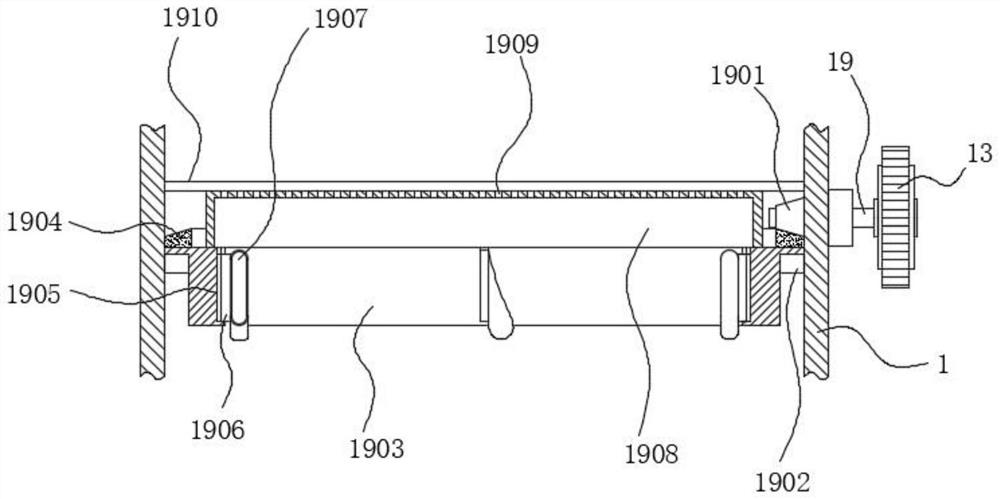

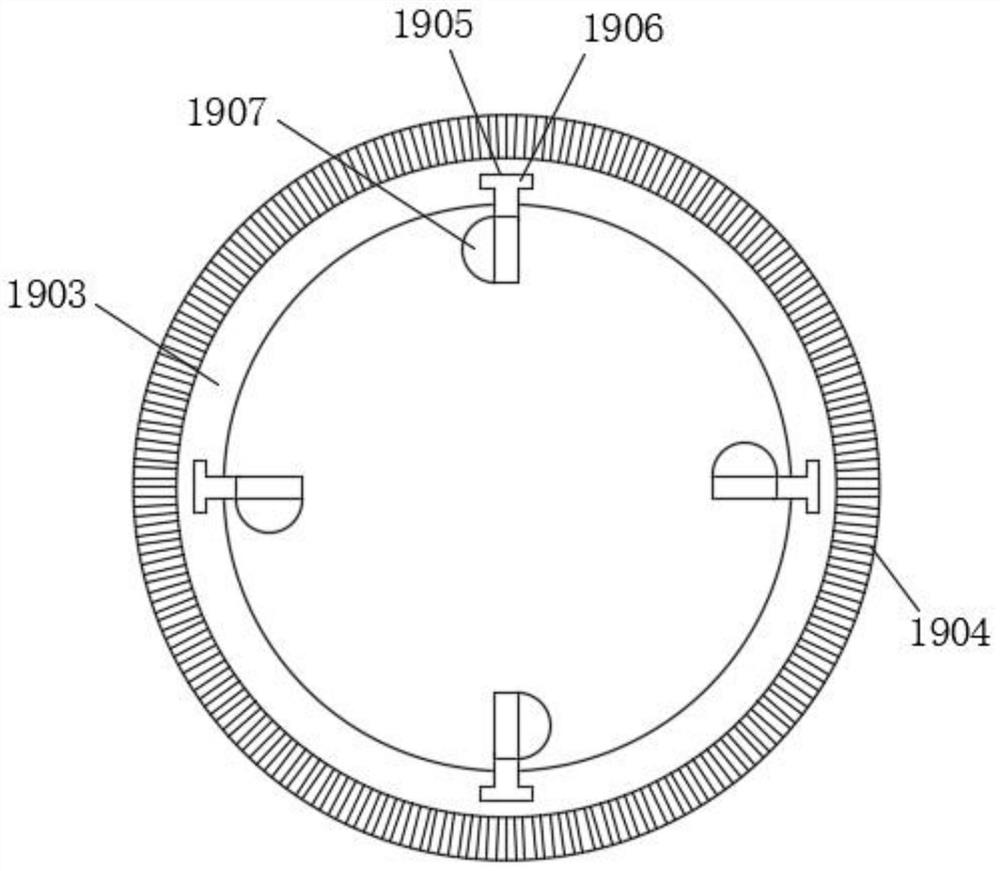

[0040] Example 1: See Figure 1-8 , a crushing type micro-power sewage treatment equipment, including a treatment tank 1 and a water inlet 9, the top of the treatment tank 1 is provided with an adsorption purification structure 8, one side of the top of the treatment tank 1 is provided with a water inlet 9, and the top of the treatment tank 1 The other side is provided with a quantitative drug feeding mechanism 12, one end of the quantitative drug feeding mechanism 12 is fixedly connected with a support 10, the top of the support 10 is provided with a solar panel 11, and the bottom end of the treatment tank 1 side is provided with a water outlet 16, and the water inlet The top of 9 and one side of the water outlet 16 are all provided with a structure 17 for splicing, the inside of the treatment tank 1 is provided with a filter slag net 15 near the bottom, and the bottom of the filter slag net 15 is provided with a buffer protection structure 18. There is a stirring and breakin...

Embodiment 2

[0044] Example 2: See Figure 1-8 , a crushing type micro-power sewage treatment equipment, including a treatment tank 1 and a water inlet 9, the top of the treatment tank 1 is provided with an adsorption purification structure 8, one side of the top of the treatment tank 1 is provided with a water inlet 9, and the top of the treatment tank 1 The other side is provided with a quantitative drug feeding mechanism 12, one end of the quantitative drug feeding mechanism 12 is fixedly connected with a support 10, the top of the support 10 is provided with a solar panel 11, and the bottom end of the treatment tank 1 side is provided with a water outlet 16, and the water inlet The top of 9 and one side of the water outlet 16 are all provided with a structure 17 for splicing, the inside of the treatment tank 1 is provided with a filter slag net 15 near the bottom, and the bottom of the filter slag net 15 is provided with a buffer protection structure 18. There is a stirring and breakin...

Embodiment 3

[0049] Embodiment 3: adsorption purification structure 8 is made up of fixed cover 801, activated carbon net 802, draw-in groove 803 and block 804, and fixed cover 801 is respectively fixedly connected to the two ends of the inner top of treatment tank 1, and the inner side wall of fixed cover 801 is uniform A card slot 803 is provided, an activated carbon net 802 is provided inside the fixed cover 801, and a card block 804 is evenly provided outside the activated carbon net 802;

[0050] The card block 804 is embedded in the card slot 803, and the card slot 803 is engaged with the card block 804;

[0051] Specifically, such as figure 1 and Figure 4 As shown, the adsorption of the activated carbon net 802 can be used to absorb and purify the odor emitted from the sewage, thereby protecting the surrounding environment. At the same time, the card slot 803 and the block 804 can facilitate the disassembly and replacement of the activated carbon net 802, and the operation is simp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com