Prefabricated assembled pier stud with main reinforcements connected through steel column welding and construction method of prefabricated assembled pier stud

A welding connection, prefabricated assembly technology, applied in the erection/assembly of bridges, bridge parts, bridges, etc., can solve the problems of difficulty in meeting the detection requirements, the grouting is not compact, and the steel bar is pulled out and damaged, so as to ensure the overall mechanical performance and Seismic performance, simple and convenient assembly and construction, and reasonable force transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

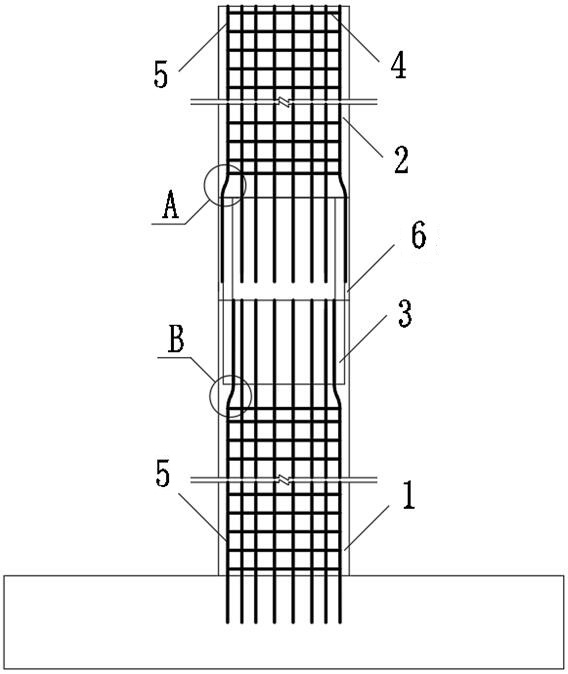

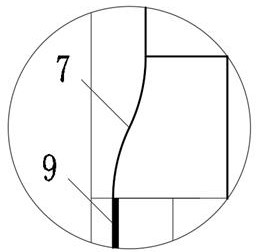

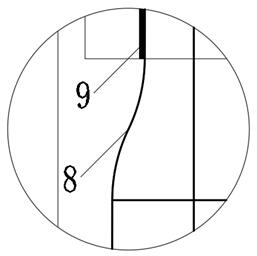

[0031] like Figure 1~4 As shown, a prefabricated assembled pier column whose main reinforcement is welded and connected by a steel column includes a concrete pier column, a longitudinal main reinforcement 5, a connecting steel column 3 and a hoop stirrup 4, and the concrete pier column is divided into an upper concrete pier column 2 and an upper concrete pier column. The lower concrete pier column 1, the upper concrete pier column and the lower concrete pier column are built with longitudinal main reinforcement and hoop stirrups, the connecting steel column is formed of a steel pipe or a steel box surrounded by steel plates, and the longitudinal main reinforcement in the lower concrete pier column is welded to the connection On the inside or outside of the ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com