Device and method for preventing cavitation and vibration of underground filling pipeline

A pipeline gas and filling pipe technology, which is applied in filling materials, safety devices, earth-moving drilling and mining, etc., can solve the problems of accelerating the corrosion rate of the pipeline, endangering the safety and stability of the filling pipeline, and strong vibration of the pipeline, saving energy consumption, Simple structure and small investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and examples, but the present invention is not limited in any way, and any changes or improvements made based on the teaching of the present invention belong to the protection scope of the present invention.

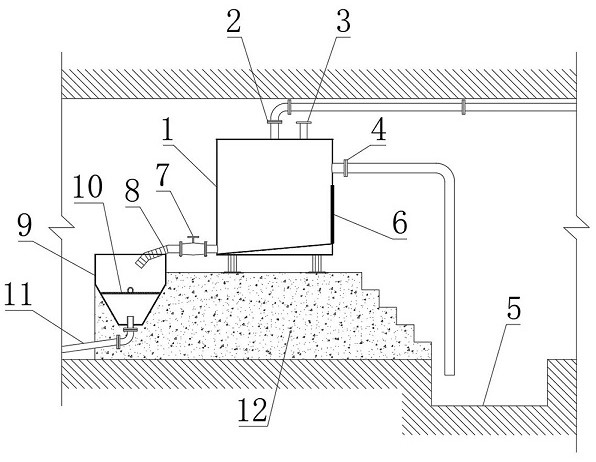

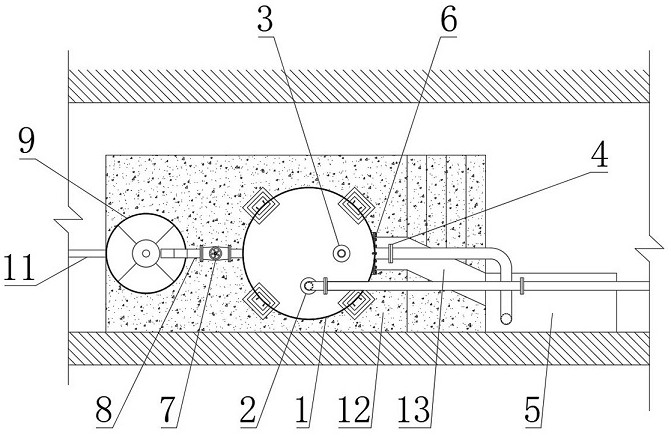

[0031] The device for preventing cavitation and vibration of underground filling pipelines of the present invention includes three parts: buffer tank 1, collecting hopper 9 and accident pool 5:

[0032] The buffer tank 1 includes a top filling pipe inlet 2, a cleaning water inlet 3, an upper side overflow port 4, a side dredging inspection port 6 and a bottom sand discharge port 8 with a valve 7;

[0033] The collecting hopper 9 includes an upper circular bin body, a middle reinforcing screen 10, a lower conical hopper and a sand outlet 11 at the bottom;

[0034] The accident pool 5 is a concrete structure sewage pool dug under.

[0035] Taking a gold mine in Hunan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com