Temperature sensor

A technology of temperature sensor and sensitive film, which is applied in thermometers, instruments, and thermometers based on the expansion/contraction of materials, etc., can solve problems such as complex structures, and achieve the effects of high precision, improved detection sensitivity, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

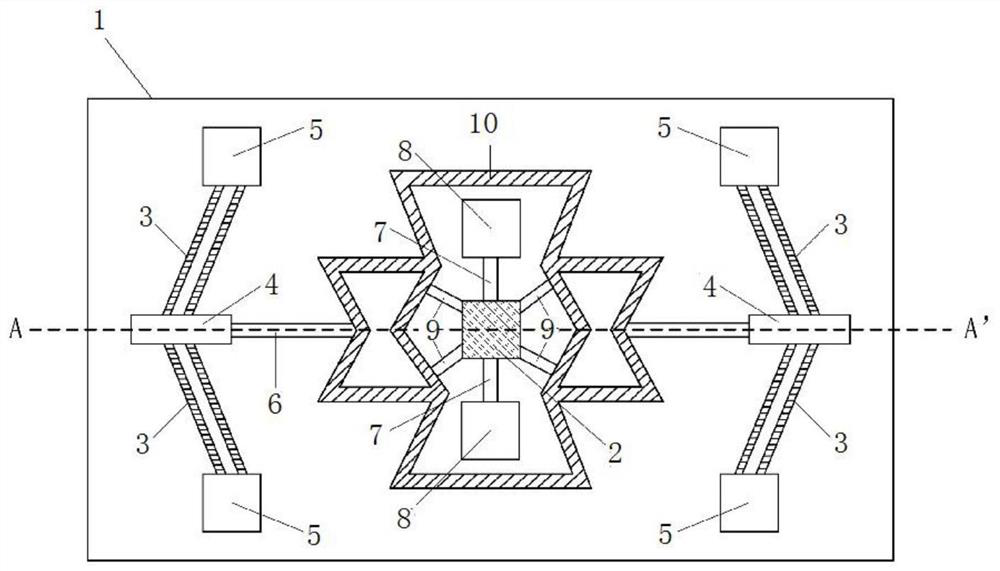

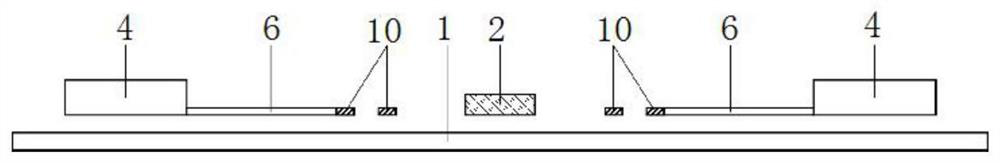

[0010] The present invention will be further explained below in conjunction with the accompanying drawings.

[0011] Such as figure 1 , figure 2 As shown, a temperature sensor includes a substrate 1, two thermally driven V-shaped beam structures, a frame-shaped mechanical metamaterial structure, and a strain-sensitive thin film 2. There are several anchor points on the base plate 1, and two heat-driven V-shaped beam structures are respectively located on both sides of the frame-shaped mechanical metamaterial structure, and are symmetrically arranged left and right. Wherein, the heat-driven V-shaped beam structure includes a pair of strip beams 3 and a strip connection block 4 between the pair of strip beams 3, one end of the strip beam 3 is fixedly connected with the strip connection block 4, and the strip beam The other end of 3 is fixedly connected with the anchor point 5 on the substrate. One ends of the two bar-shaped connecting blocks 4 are respectively connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com