Rotating pressure calibration device and method

A technology of calibration device and calibration method, which is applied in the direction of measurement device, measurement of fluid pressure, engine test, etc., can solve the problems of low calculation accuracy, cumbersome calibration work, limited rotor speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

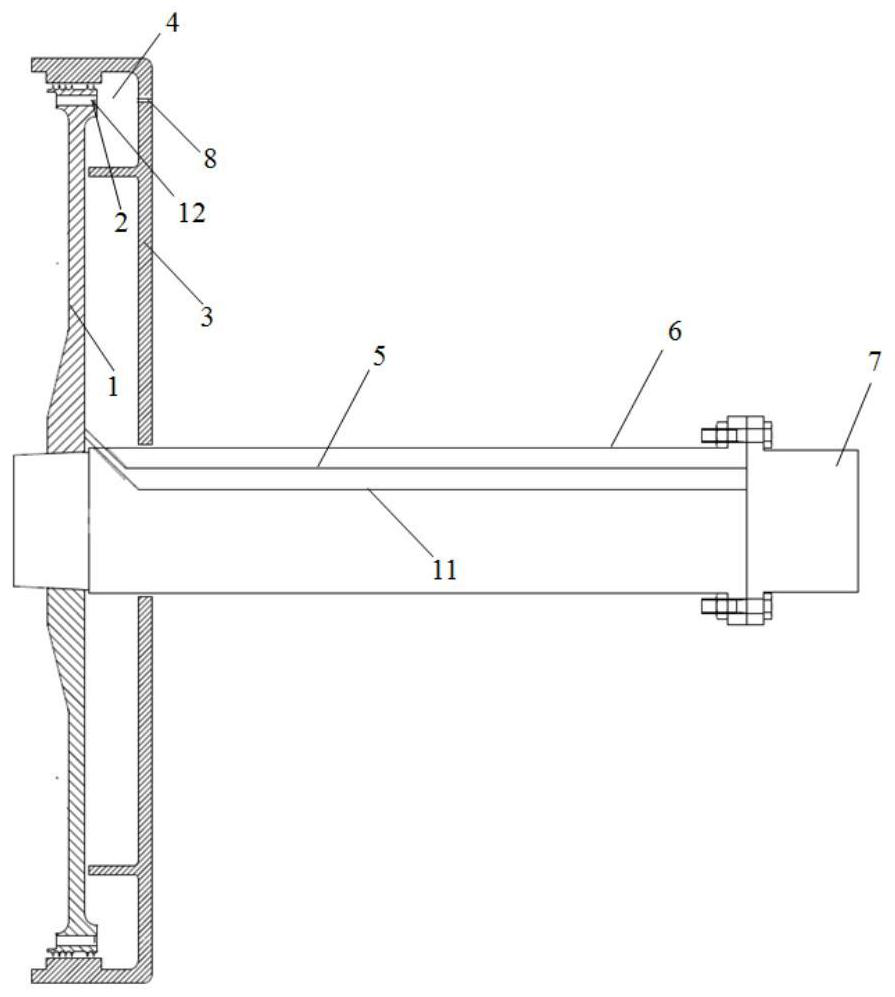

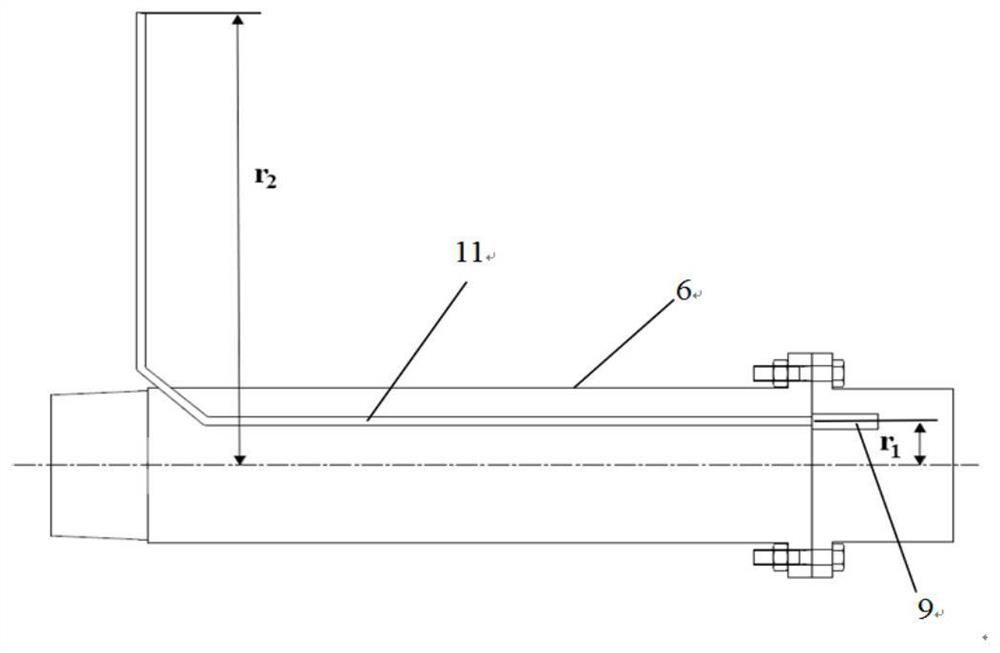

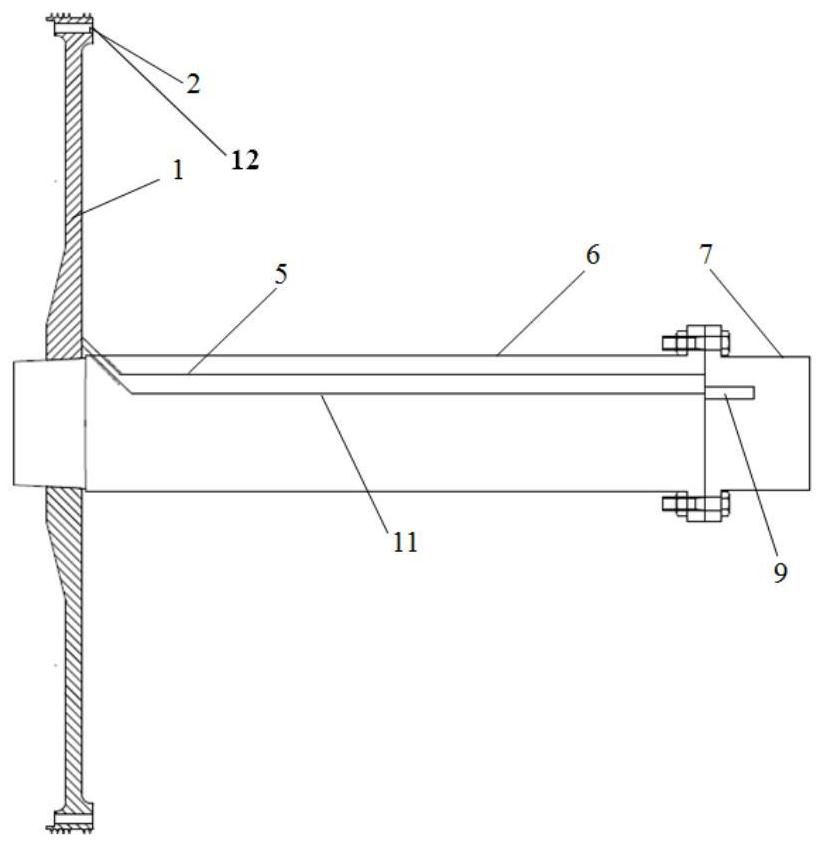

[0064] The experimental device of this embodiment includes a turntable 1 , a stationary casing 3 , a hollow shaft 6 , a data recorder 7 , a pressure sensor 9 , a thermocouple 5 and a pressure introduction tube 11 . Wherein, the turntable 1 is set on one end of the hollow shaft 6 , and an interference fit is made between the turntable and the hollow shaft; the data recorder 7 is installed on the end surface of the other end of the hollow shaft 6 . The stationary case 3 is sleeved on the hollow rotating shaft and is located inside the turntable; the inner circumferential surface of the outer ring of the stationary case corresponds to the outer circumferential surface of the turntable, and makes the inner surface of the outer ring of the stationary case There is a gap of 0.5mm between the circumferential surface and the outer circumferential surface of the turntable, and the distance between the inner end surface of the turntable and the inner end surface of the stationary casing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com