High-speed wire rod quality defect diagnosis and traceability method based on distributed Bayesian network

A Bayesian network, high-speed wire technology, applied in character and pattern recognition, instruments, computer parts, etc., can solve problems such as twist, can not meet the requirements of high-speed wire diagnosis and traceability, scratches, etc., to achieve flexible information fusion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

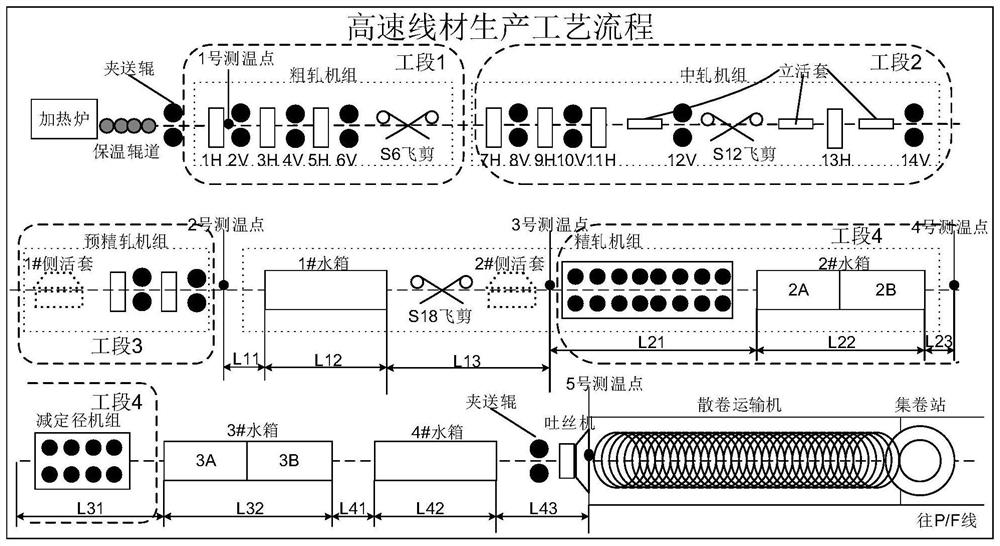

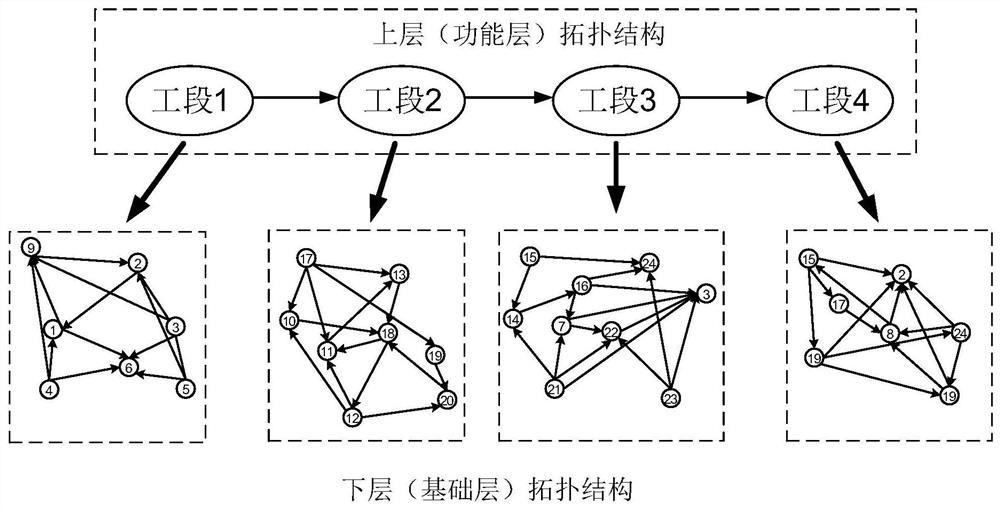

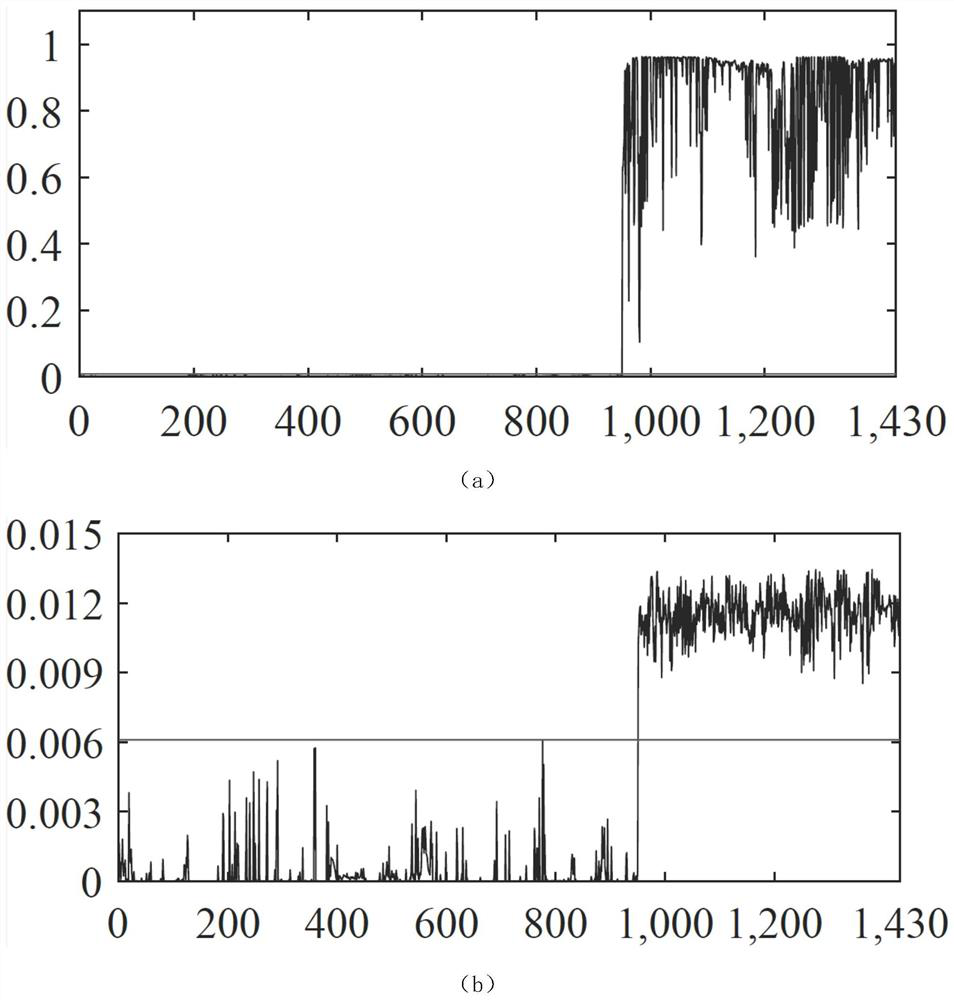

[0061] The invention discloses a high-speed wire rod quality defect diagnosis and source tracing method based on a distributed Bayesian network. This method first collects the normal working condition data of the steel high-speed wire rolling process, combines the process mechanism and the big data of the production process, decomposes the whole production process into several sections, and then builds a distributed shell with multi-layer structure based on the data characteristics and process knowledge. The Yeesian network constructs local monitoring statistics, global monitoring statistics, local contribution and global contribution, and finally realizes the diagnosis and traceability of high-speed wire quality defects through information fusion.

[0062] Specific steps are as follows:

[0063] Step 1: Collect the normal working condition data of the high-speed wire rolling process to obtain the training sample set for modeling with process variable set M;

[0064] Step 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com