Test method and test system based on depth estimation performance of depth camera

A depth camera and depth estimation technology, applied in computing, image data processing, instruments, etc., can solve problems such as single scene, poor performance of depth estimation performance, difficulty in reflecting the performance of depth estimation of the entire image, etc., to achieve high The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

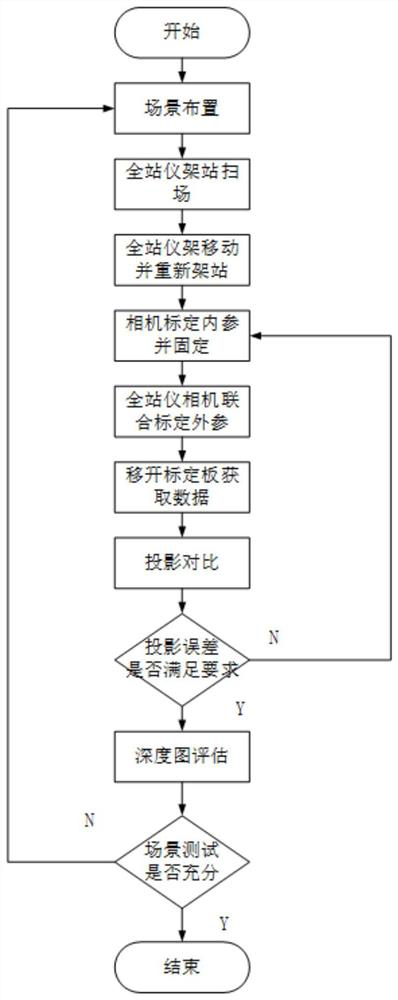

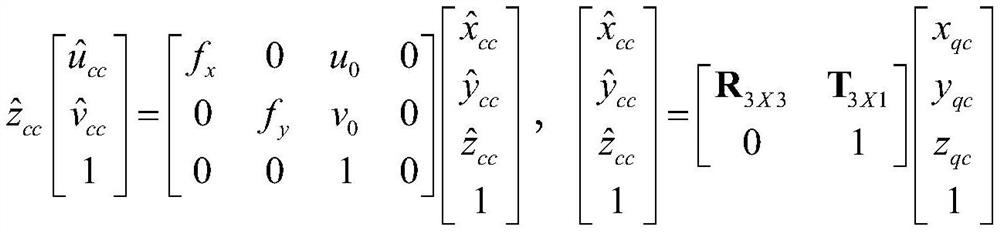

[0036] In view of the deficiencies of the existing testing methods, this embodiment proposes a testing method for the depth map of the depth camera, which obtains the true value of the depth map through laser total station sweeping, joint calibration of the camera and total station, and point cloud back projection , to conduct a more comprehensive evaluation by directly comparing the depth map, and at the same time have rich scenes that are not limited by physical devices, and have higher accuracy. Provide more objective, comprehensive and effective R&D and testing services for the performance of depth cameras to accelerate the development process and problem iterations of depth cameras. For this purpose, a corresponding test method for depth estimation performance of depth cameras and a laser total station, scene props, The calibration board, the camera bracket, and the computer form a set of test system to realize the above test method. The current method is aimed at a depth ...

Embodiment 2

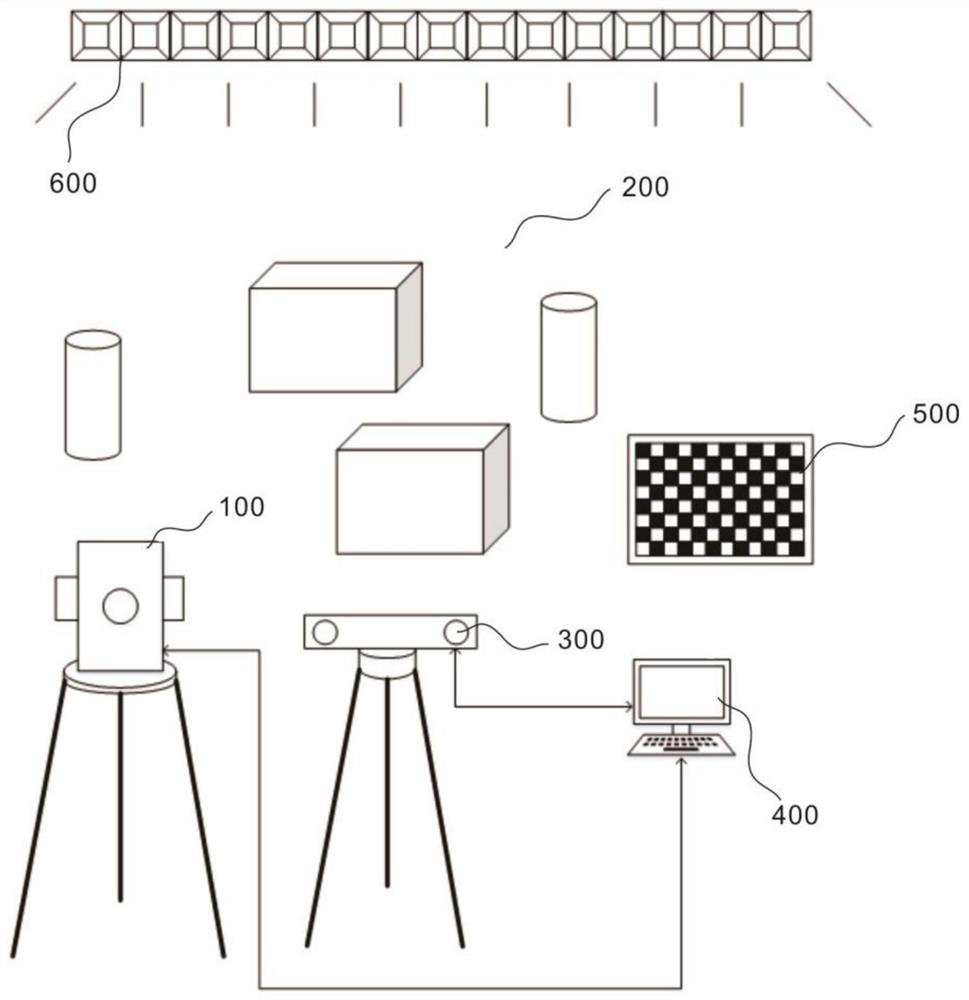

[0095] refer to figure 2 The figure shows a laser total station 100 , a test scene 200 , a depth camera 300 , a host computer 400 , a checkerboard calibration board 500 , and an environment control device 600 . In this embodiment, a test system based on the depth estimation performance of a depth camera is proposed, including a depth camera 300 , a computer, and a laser total station 100 . More specifically, the depth camera 300 is a sensor to be tested, capable of acquiring depth maps, color or black and white images; the computer (ie, the host computer 400) is used to collect images and depth information output by the depth camera, and is capable of calibration and data analysis and processing equipment , and the computer is equipped with relevant SDK and codes collected by the depth camera 300, algorithm codes for calibration of internal and external parameters, relevant codes for reading and analyzing total station data, and relevant algorithm codes for data processing an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com