Vulcanized rubber composition, tire tread and tire

A rubber composition, vulcanized rubber technology, applied in the direction of tire tread/tread pattern, special tires, tire parts, etc. Excellent wear resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

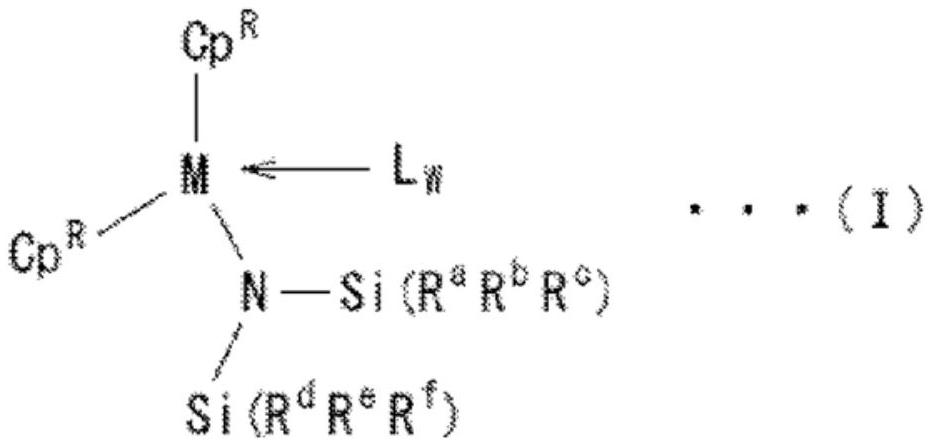

[0110] (Si). The metalloid group preferably has the same hydrocarbon group as the above-mentioned hydrocarbon group. Specific examples of metalloid groups include trimethylsilyl groups. Cp having a cyclopentadienyl ring as a basic skeleton R’ The specific examples are as follows:

[0111]

[0112] (wherein R represents a hydrogen atom, a methyl group or an ethyl group).

[0113] In general formula (III), Cp having an indenyl ring as a basic skeleton R’ is similarly defined as Cp of general formula (I) and (II) R , and preferred examples are the same as above.

[0114] In the general formula (III), Cp having a fluorenyl ring as a basic skeleton R’ can be made by C 13 h 9-x R x or C 13 h 17-x R x express. Here, X is an integer of 0-9 or 0-17. Each R is preferably independently a hydrocarbyl or metalloid group. The hydrocarbon group preferably has 1 to 20 carbon atoms, more preferably has 1 to 10 carbon atoms, and further preferably has 1 to 8 carbon atoms. Pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com