Mining dump truck lifting seat

A technology for mining dump trucks and carriages, which is applied in the direction of inclined load-carrying vehicles, etc., which can solve the problems of high manufacturing cost, large sudden change in stiffness, and stress concentration, so as to avoid stress concentration and sudden change, reduce the influence of torsion, and uniform stress scattered effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

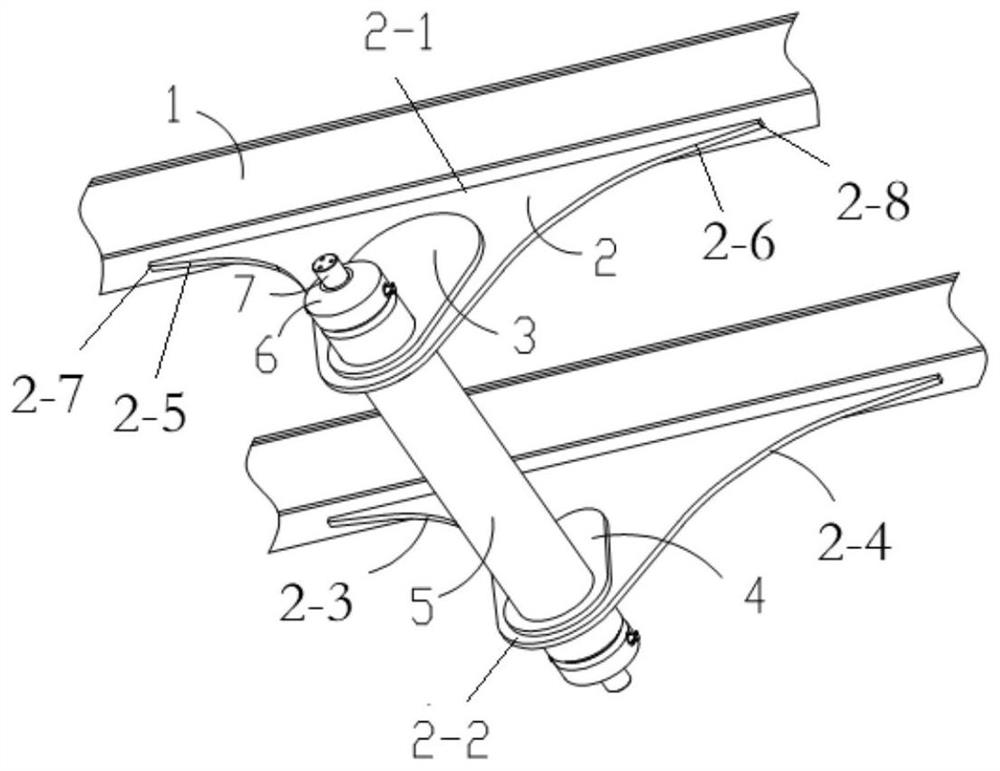

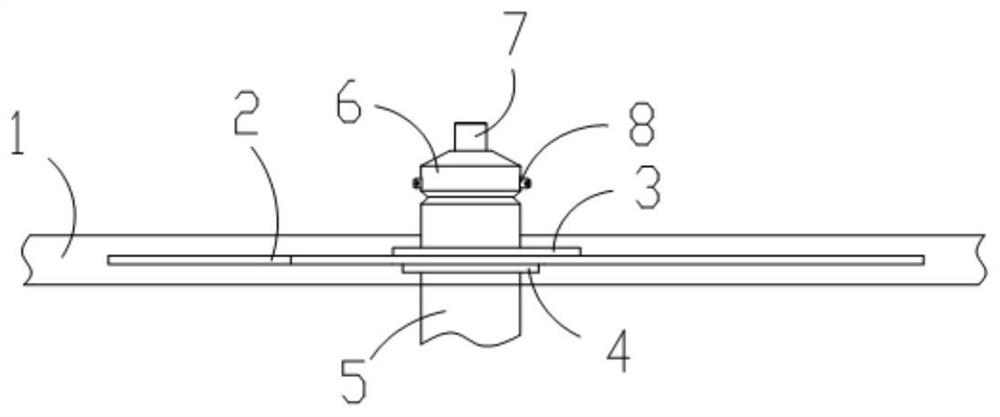

[0022] As a specific embodiment of the present invention, the top sides 2-1 of the left and right lifting arc plates 2 are fixedly connected with the left and right longitudinal beams 1 by welding. But the front end portion 2-7 of the top edge and the rear end portion 2-8 of the top edge and the left and right longitudinal beams 1 are not welded, that is, the front and rear ends of the top edge 2-1 are not welded with the left and right longitudinal beams 1 and there is a gap, so that This place only bears compressive stress but not tensile stress, which can reduce the stress amplitude, thereby reducing the influence of stress fatigue on the left and right longitudinal beams 1 and the left and right lifting arc plates 2 . Of course, as other specific embodiments of the present invention, it is also possible to set arc blocks at the front and rear end points of the top edge 2-1 that can increase the welding surface with the left and right longitudinal beams 1, so as to ensure th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com