Automatic equipment for coating imitated pearls with oil

A kind of automation equipment and imitation pearl technology, applied in the direction of lighting and heating equipment, conveyor objects, furnaces, etc., can solve the problems of labor-intensive workers, low output, low efficiency, etc., and achieve the effect of reducing laborers and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

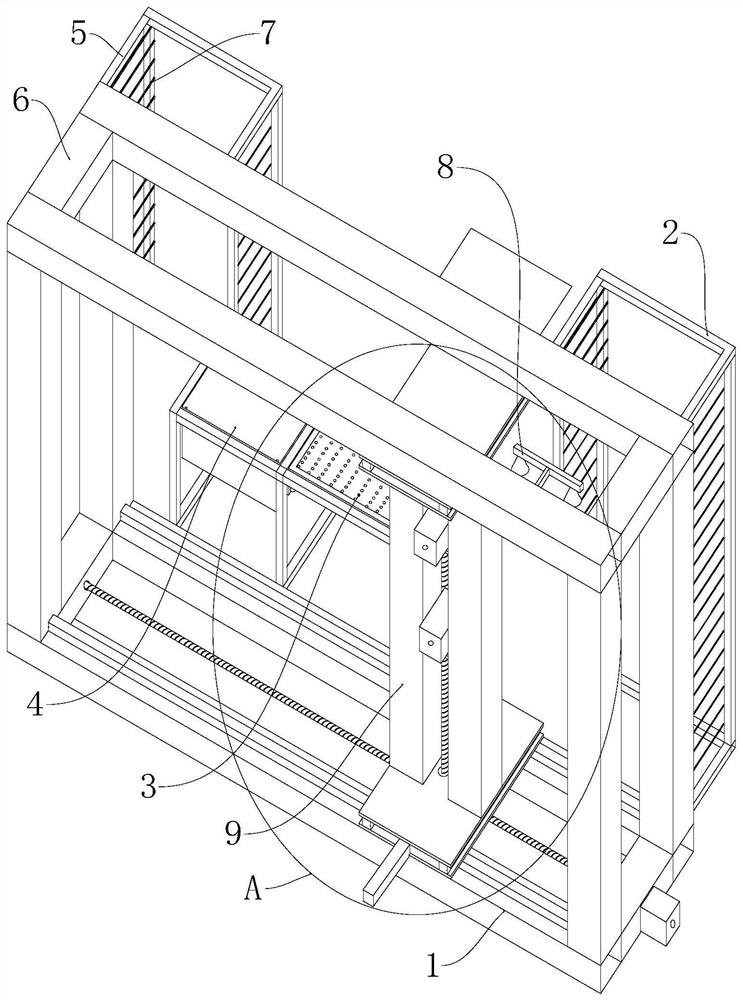

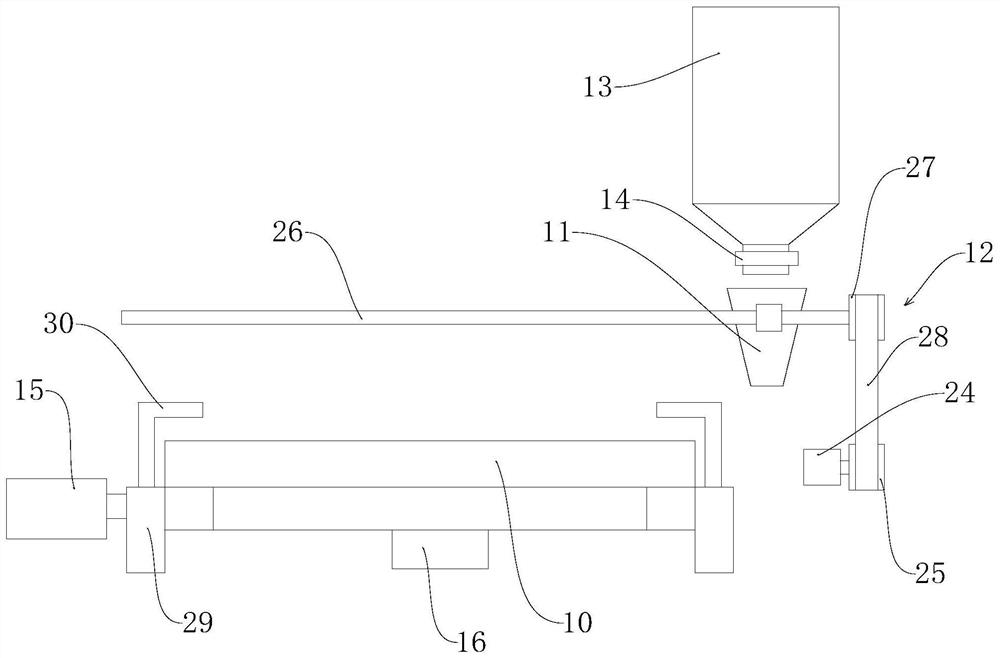

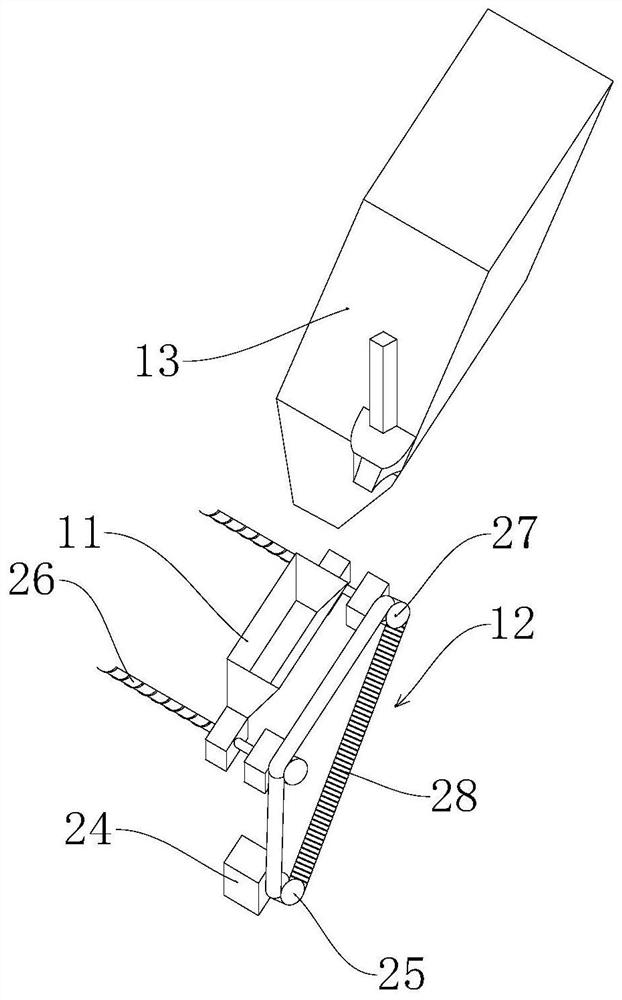

[0026] refer to Figure 1-5 , a kind of imitation pearl ferry oil automation equipment, comprises base 1, and base 1 is provided with feeding bin 2, swinging mechanism 3, oil tank 4, receiving bin 5 in sequence. The upper silo 2 and the receiving silo 5 are respectively provided with support mechanisms 7 for placing multi-layer trays, the support mechanisms 7 are respectively located on the inner walls of both sides of the upper hopper 2 and the receiving silo 5, and the support mechanisms 7 are arranged in pairs The support plates on the inner walls on both sides are suspended structures, and the upper and lower support plates are arranged at intervals. The feeding tray is placed across the supporting plates on both sides, and the feeding tray is provided with adhesive glue, which is specifically arranged on the top surface of the feeding tray for sticking imitation pearls. One side of the base 1 is provided with a feeding bracket 6 , and the feeding bracket 6 is provided wi...

Embodiment 2

[0039] refer to Figure 6 , 7, on the basis of Embodiment 1, the other side of the base 1 is provided with a receiving bracket 19, and the receiving bracket 19 is provided with a receiving grabbing member 20 for grabbing a tray and a mechanism for driving the receiving grabbing member 20 to move. The fourth driving mechanism 21 . The material receiving gripper 20 includes a material receiving suction cup 22 and a material receiving connecting frame 23 connected to the material receiving suction cup 22 , and the material receiving connecting frame 23 is connected to the fourth driving mechanism 21 . The 4th driving mechanism 21 comprises the 3rd slide table 42, is provided with the guide rail that slides and installs the 3rd slide table 42 on the base 1, connects the second translation lead screw 43 of the 3rd slide table 42 by the screw nut, connects the second translation wire The second screw motor of bar 43, the 3rd slide table 42 is provided with the 4th slide table 44 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com