Broken and soft coal seam closed coring drill bit suitable for ground drilling

A technology for coring drill bits and soft coal seams, which is applied in the direction of drill bits, drilling tools, drilling equipment, etc., can solve the problems of not taking coal cores, coal body washing away, and low drilling efficiency, so as to reduce denudation and improve recovery rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

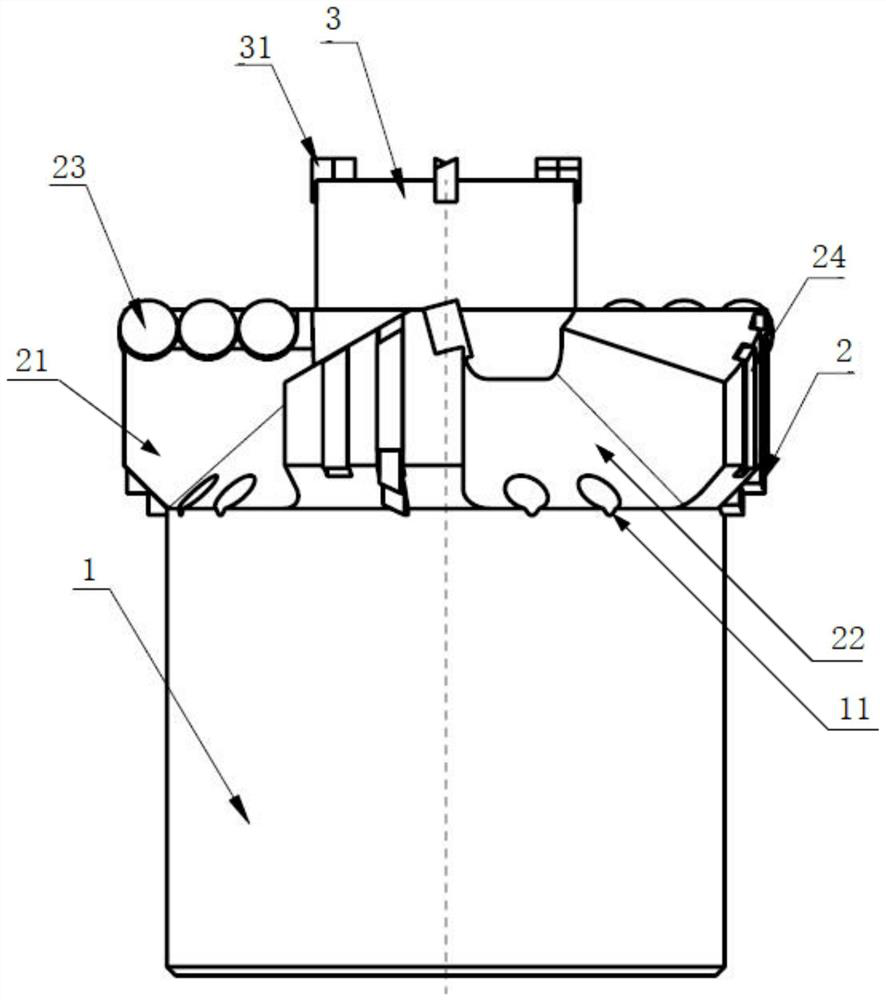

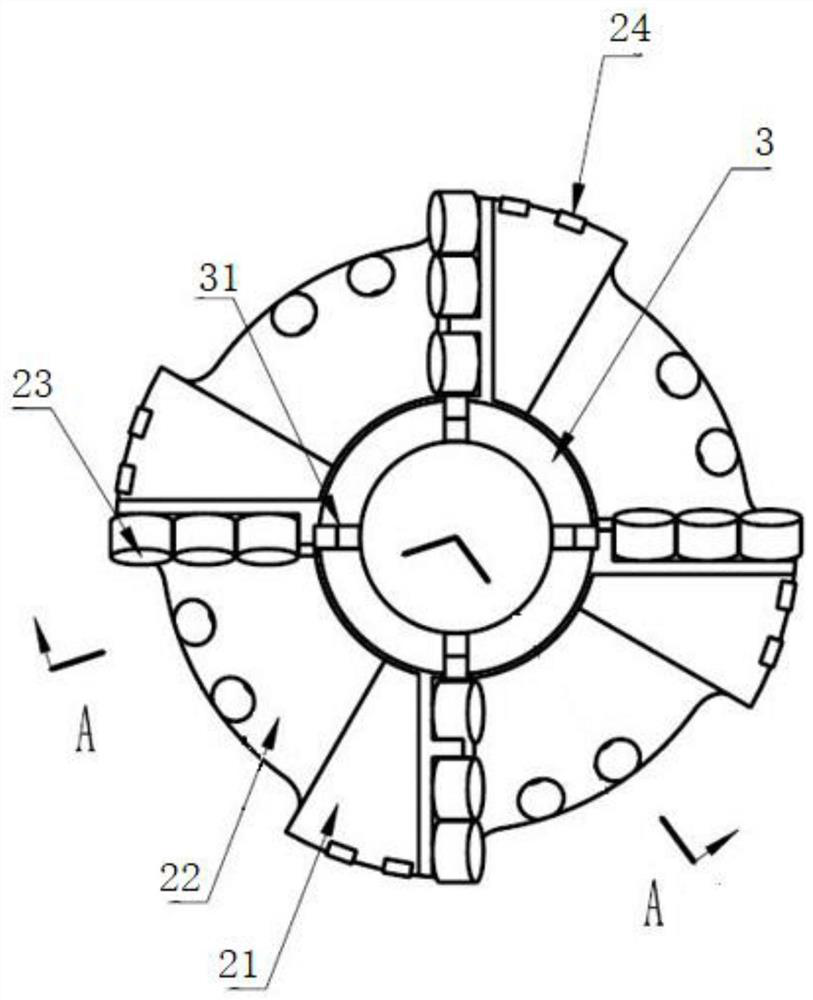

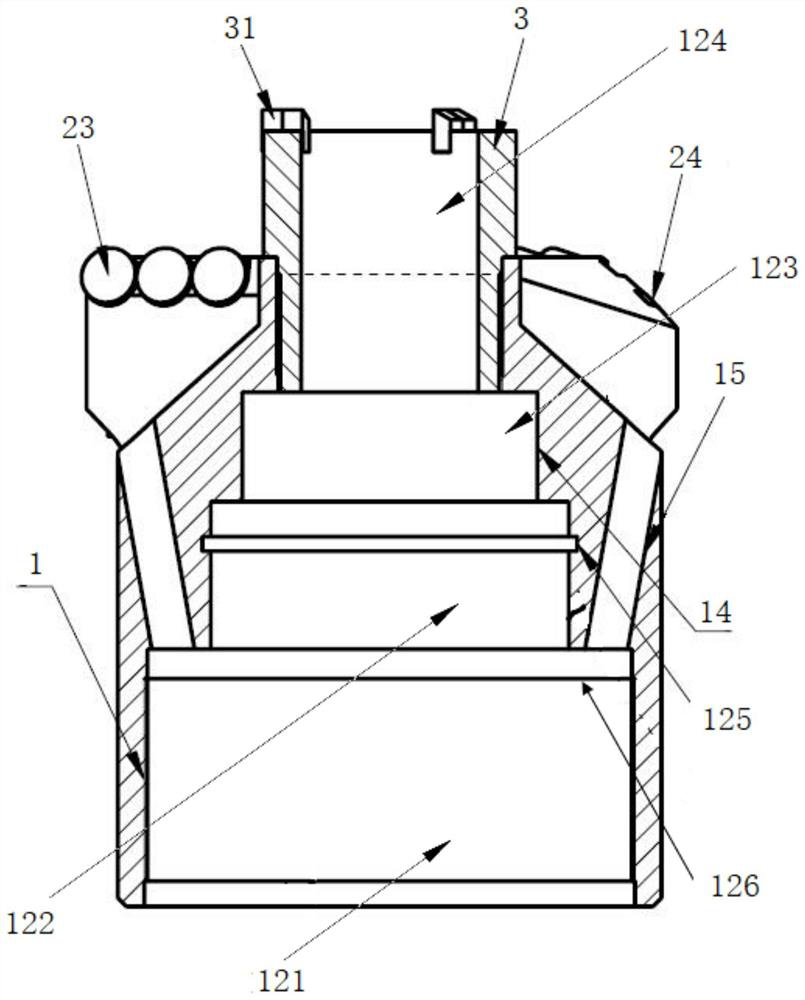

[0033] refer to Figure 1 to Figure 3 , the present embodiment discloses a sealed coring drill bit for soft coal seams suitable for ground drilling, including a drill body 1 , an outer drill bit 2 and an inner drill bit 3 .

[0034] Among them, the drill body 1 is a tubular structure, and its front end is a hollow circular platform structure. The center hole of the drill body 1 is a three-step hole whose diameter increases from front to back. The outer drill bit 2 is fixed on the outer ring of the front end of the drill body 1. The outer ring wall of the outer drill bit 2 is provided with a plurality of cutting wings 21 at intervals in the circumferential direction, and a diversion groove 22 is formed between any two adjacent cutting wings 21, and each cutting wing 21 is inlaid with an outer cutting tooth 23 and a retainer Diameter teeth 24, the rear end of the inner drill bit 3 is detachably connected to the small-diameter hole section 124 of the three-step hole, the front en...

Embodiment 2

[0044] Such as Figure 4 As shown, a kind of airtight coring bit suitable for ground drilling provided in this embodiment also includes a compression spring 4 and an end cap 5, the outer ring wall of the end cap 5 has an external thread, and the inner wall of the end cap 5 is in line with the The circular hole wall matched with the outer ring wall at the rear end of the inner drill bit 3 .

[0045] The rear end inner wall of the small-diameter hole section 124 of the three-step hole extends radially inward to form a first retaining ring 127, and the front end inner wall of the small-diameter hole section 124 of the three-step hole has an internal thread. There is a compression spring 4, the rear end of the compression spring 4 presses against the front end of the first retaining ring 127, and a second retaining ring 32 is arranged on the circumference of the outer ring wall at the rear end of the inner drill bit 3, and the second retaining ring 32 resists The front end of the...

Embodiment 3

[0048] Such as Figure 5 with Image 6 As shown, a closed coring bit suitable for ground drilling provided in this embodiment is further optimized based on Embodiment 2, and its optimization is as follows:

[0049] The water hole 11 is equipped with a partition net, which includes a mesh ring 71 and a mesh 72 arranged in the mesh ring 71 and can swing axially along the mesh ring 71. The water hole 11 is also equipped with a mesh return device, the mesh return device is used to control the stretching of the mesh 72.

[0050] The mesh return device includes a grid frame 73 and a telescopic piece 74 , the fixed end of the telescopic piece 74 is connected to the center of the grid frame 73 , and the telescopic end of the telescopic piece 74 is affixed to the center of the mesh piece 72 .

[0051] During coring, the high-pressure drilling fluid sprayed from the water eye 11 impacts the mesh 72, causing the mesh 72 to stretch toward the front side of the water eye 11. The posteri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com