Ultralow-temperature refrigerating box and refrigerating method

A refrigerated box and ultra-low temperature technology, applied in coolers, household refrigerators, household refrigeration devices, etc., can solve the problems of ultra-low temperature refrigerated trucks, refrigerated boxes, immature technology, not an economical way, and inflexible transportation, etc. Save time, avoid heat transfer, small heat leakage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

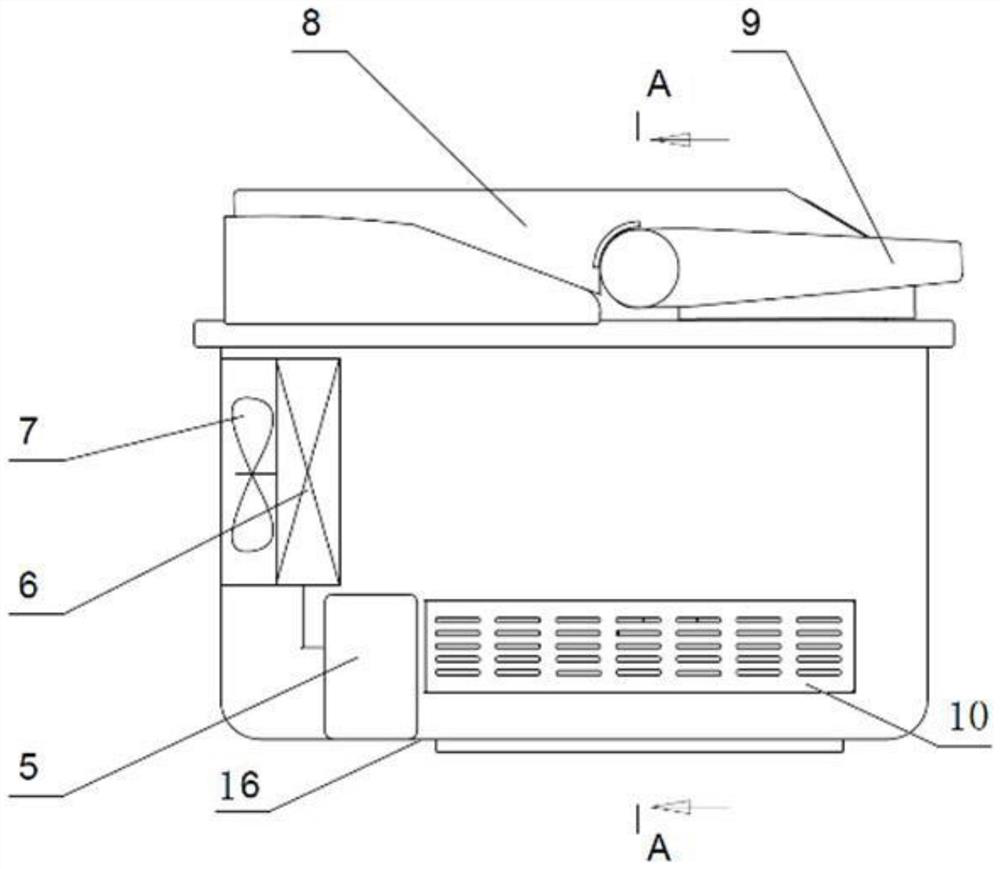

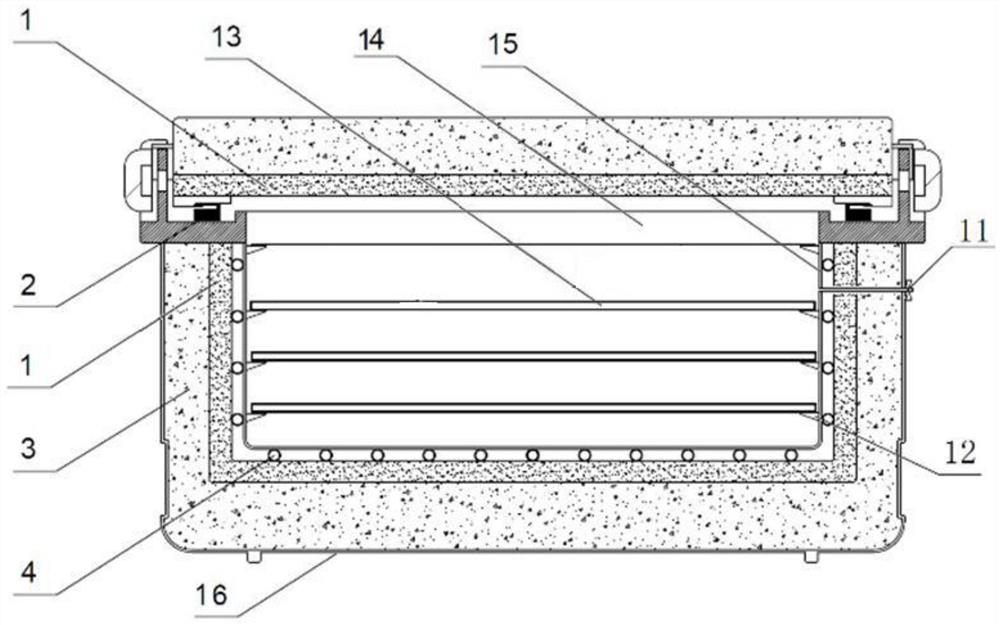

[0028] Embodiment 1: as figure 1 and 2 As shown, an ultra-low temperature refrigerator includes a box body 16 and a mixed working medium refrigeration system. The box body 16 is equipped with a box cover 8, and the inner wall of the box body 16 is sequentially provided with an insulation layer 3, a heat insulation board 1, and an evaporation The copper pipe 4 and the inner plate 15, the gas interface 11 is provided on the box body 16, and the valve 11 is provided on the gas interface 11.

[0029] Thermal conductive glue is filled between the evaporator copper tube and the wall surface of the inner plate 15 . Fill the box with carbon dioxide through the gas interface, and lower the temperature inside the box to -80 degrees. Because the curing temperature of carbon dioxide is -78 degrees. The carbon dioxide will turn into a solid, and the pressure in the chamber drops sharply, creating a vacuum. The convective heat exchange between the tuna and the wall is prevented. Once t...

Embodiment 2

[0030] The difference between embodiment 2 and embodiment 1 is: the wall surface of the inner panel 15 is provided with reinforcing ribs at positions where there is no evaporator copper tube.

Embodiment 3

[0031] The difference between embodiment 3 and embodiment 2 is: the inner plate 15 and the reinforcing rib are all made of stainless steel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com