5G real-time dynamic fault processing system based on multidimensional sensor

A real-time dynamic, processing system technology, applied in database management systems, services based on specific environments, manufacturing computing systems, etc., can solve problems such as economic losses, casualties, etc., and achieve a high degree of consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

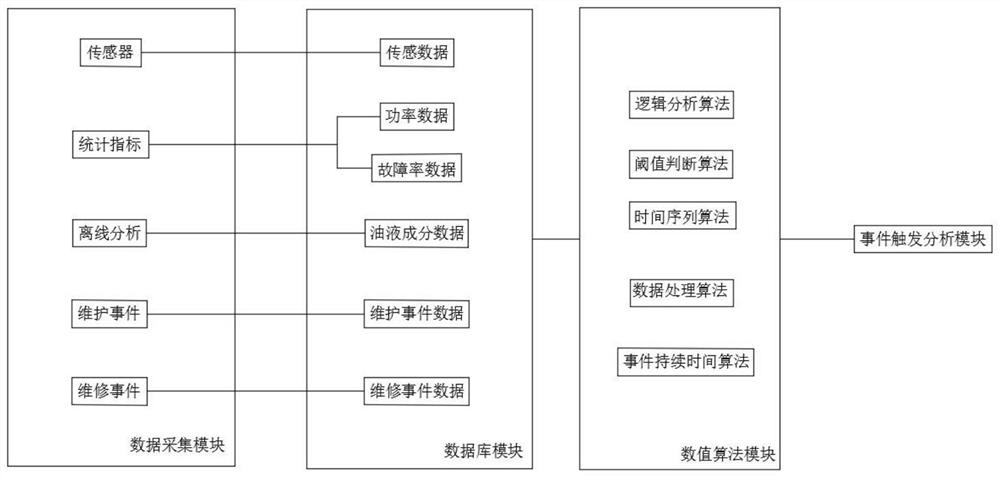

Method used

Image

Examples

Embodiment 1

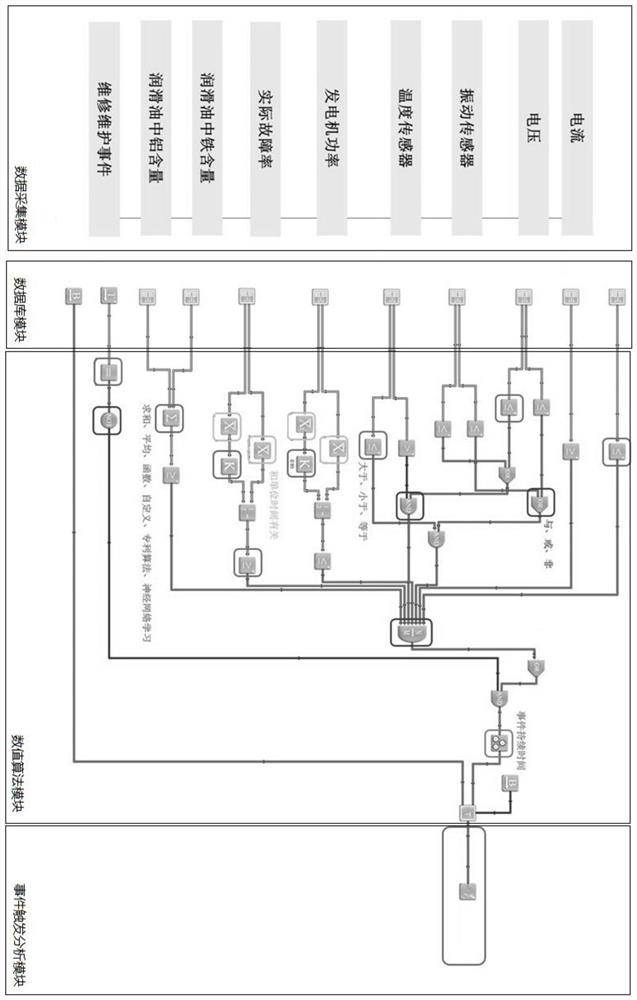

[0047] Using this system for intelligent gas turbine status monitoring and key performance index analysis and continuous catalyst regeneration reformer process key performance index analysis, real-time detection of production planning, product quality, output, energy consumption, asset reliability and other working standards;

[0048] The continuous regenerative reformer (CCR) is used for the catalytic reforming process of the continuous regeneration catalyst. Three parallel reforming reactors are used in the processing flow. The catalyst moves in series, and the feed oil and the catalyst flow in parallel, before entering each reactor. All are heated by the heating furnace, and the catalyst from the last reactor enters the regeneration lifting system, and returns to the first reactor after regeneration;

[0049] The key performance indicators that need to be monitored include production indicators, performance indicators, quality indicators, energy indicators, and maintenance i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com