Multi-objective optimization method for injection molding process parameters of glass fiber reinforced plastics

A multi-objective optimization and process parameter technology, which is applied in the field of multi-objective optimization of glass fiber reinforced plastic injection molding process parameters and injection process parameter optimization to achieve the effect of satisfying dimensional accuracy and reducing warpage and volume shrinkage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

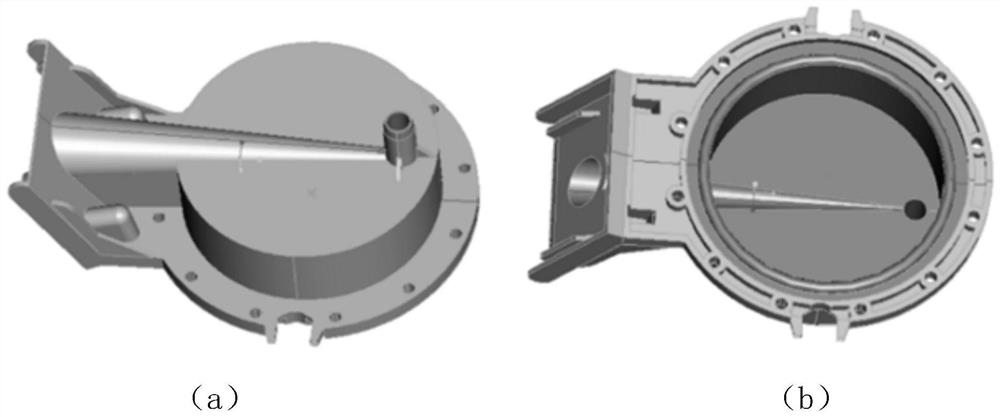

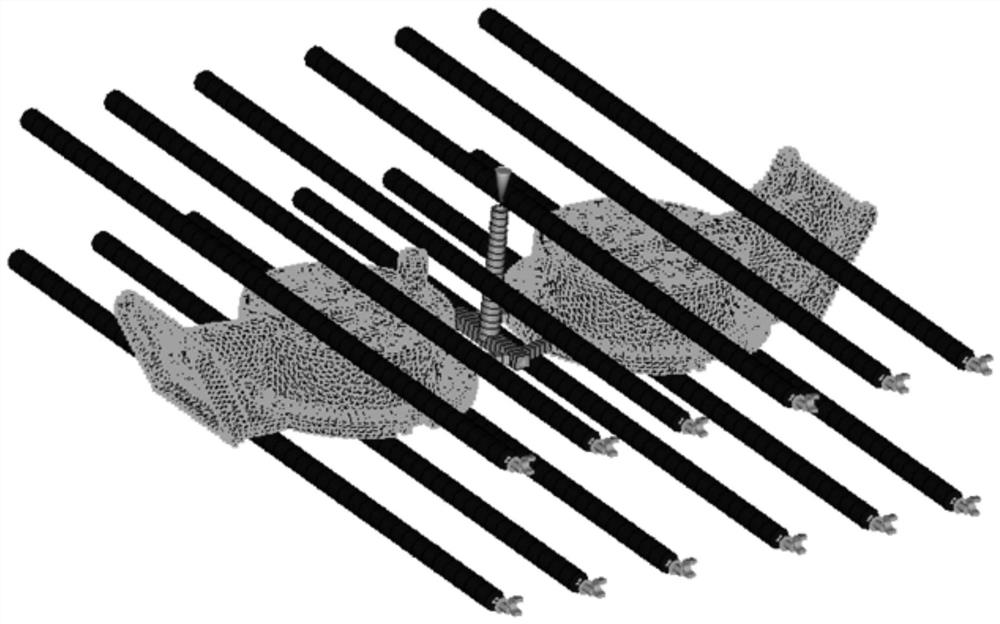

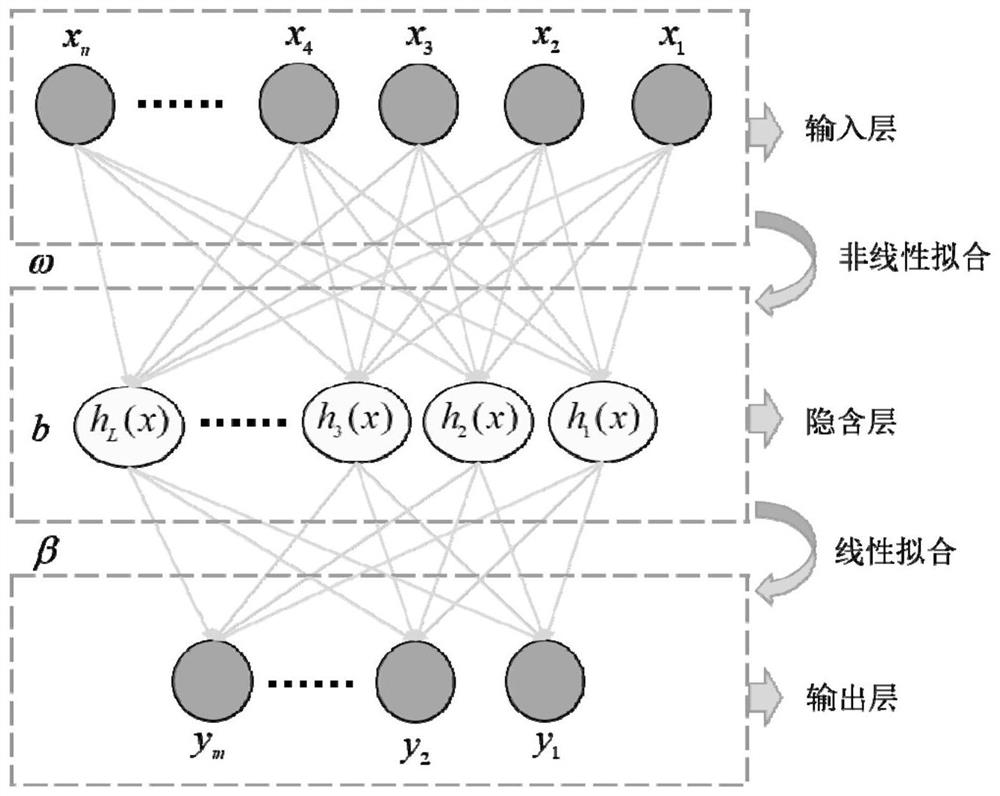

[0062] This multi-objective optimization method for glass fiber reinforced plastic injection molding process parameters aims at the two-objective optimization problem of warpage and volume shrinkage of glass fiber reinforced plastic plastic parts. sample points with a reasonable distribution, and simulated by Moldflow software to obtain the warpage value and volume shrinkage rate of each sample point; then based on the sample results obtained by Latin Hypercube Sampling (LHS), the extreme learning machine model based on genetic algorithm is used (GA-ELM) to establish a nonlinear mathematical model between process parameters and quality objectives; then use the multi-objective firefly algorithm (MOFA) to optimize the two-objective problem; And the GRA-TOPSIS method of Gray Relational Analysis (GRA) evaluates to obtain the optimal scheme and the corresponding optimal injection molding process parameters.

[0063] Hereinafter, the present invention will be specifically described ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap