Complex wiring harness tool plate design system

A design system and tooling drawing technology, applied in computer-aided design, calculation, instruments, etc., can solve the problems of high design intensity, error-prone, low efficiency, etc., to ensure the accuracy of wiring, improve efficiency, save manpower and material technology cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Below in conjunction with accompanying drawing and embodiment further illustrate technical scheme of the present invention:

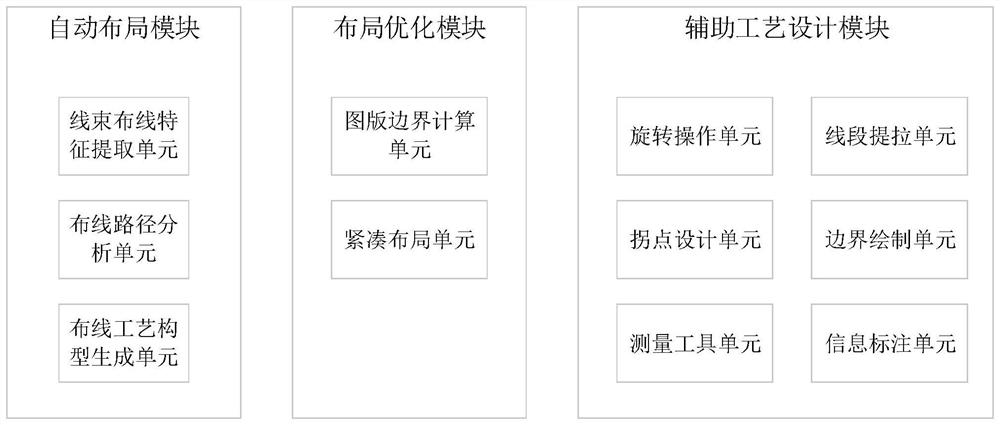

[0045] A tooling design system for complex wire harnesses, including:

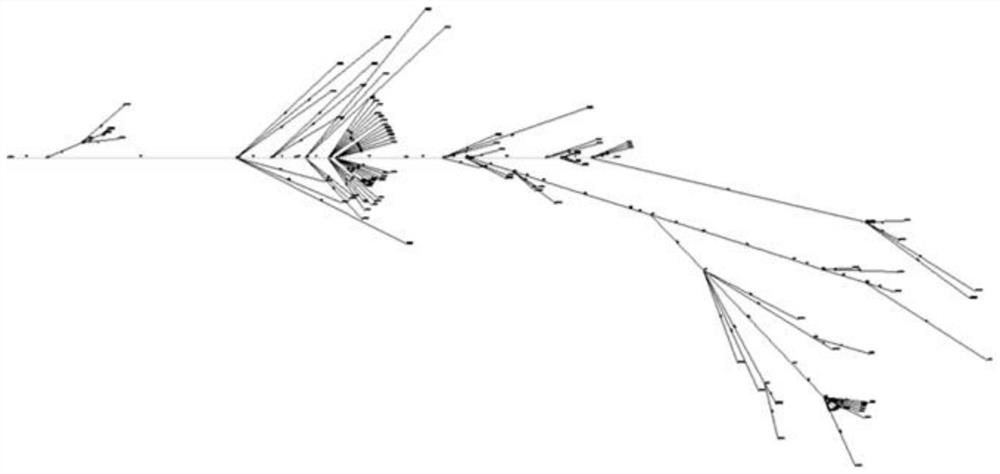

[0046] Automatic layout module: analyze the data in the circuit schematic diagram and the wire table, extract the characteristic elements of the wiring harness wiring, arrange the wiring harness wiring path, and perform the layout of the wiring process configuration;

[0047] Layout optimization module: according to the boundary size requirements of the process layout, optimize the layout of the wiring process configuration completed by the automatic layout module, so that the optimized wiring harness layout meets the engineering wiring requirements, and obtain the wiring harness tooling layout;

[0048] Auxiliary process design module: Provides a common drawing function module for wiring tooling layout design, which is used for designers to modify the wiring process layout o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com