Method for forming copper layer on circuit board and circuit board with sputtered copper layer

A technology for electroplating copper layers and circuit boards, which is used in printed circuits, printed circuit manufacturing, electrical components, etc., and can solve the problems of high cost of electroless copper plating, complex composition of plating solution, and high process difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The invention discloses a method for forming a copper layer on a circuit board and a circuit board with a sputtered copper layer. The method is widely compatible with the copper layer setting process in the existing circuit board manufacturing process, and in particular can replace electroless plating copper process.

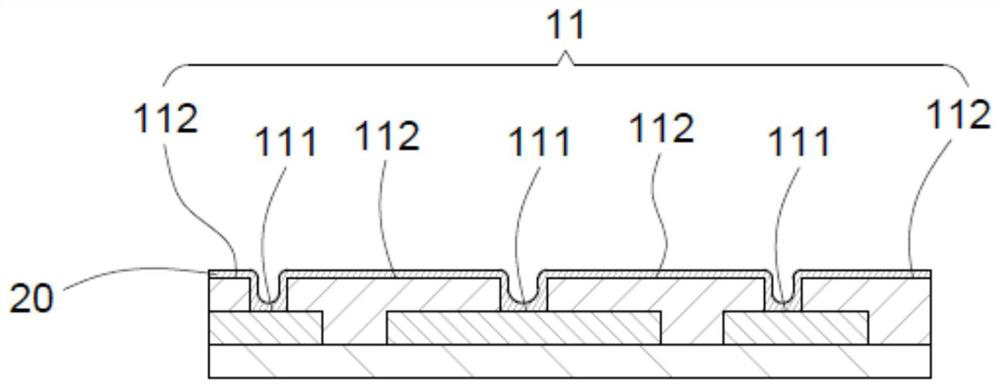

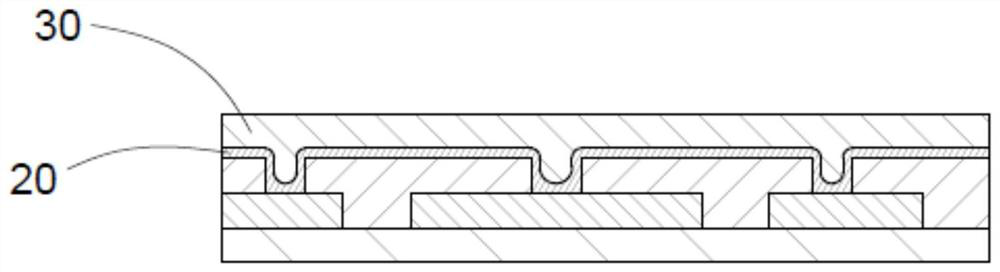

[0019] The following pass Figure 1 to Figure 7 The manufacturing process of one embodiment of the present invention is described.

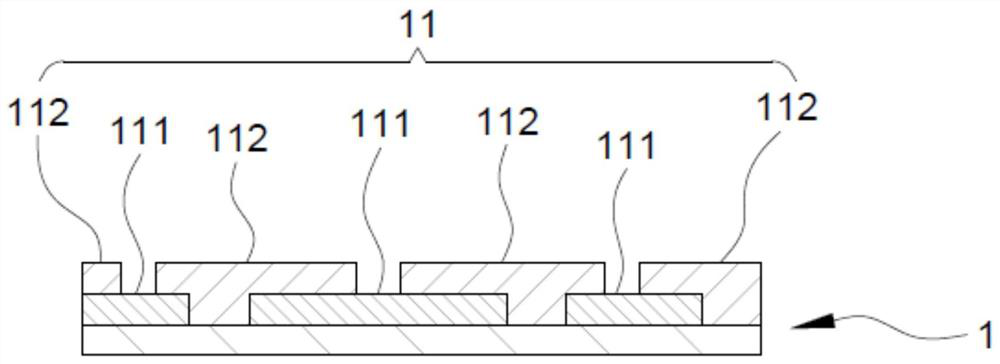

[0020] Please refer to figure 1 , at first, provide a circuit board structure 1, this circuit board structure 1 has a surface 11 to be plated, the surface 11 to be plated has a conductive area 111 and a non-conductive area 112, and the quantity of the conductive area and the non-conductive area 112 depends on the circuit design , in a circuit board structure with high circuit design complexity, the surface 11 to be plated may have a large number of conductive regions 111 and non-conductive regions 112 . It can be understo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com