Low-temperature-doped luminescent aluminum nitride thin film and preparation method thereof

A technology of aluminum nitride and thin film, which is applied in the field of low-temperature doped luminescent aluminum nitride thin film and its preparation, can solve the problems of large particle pollution of arc ion plating thin film, and achieve the effect of easy operation and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

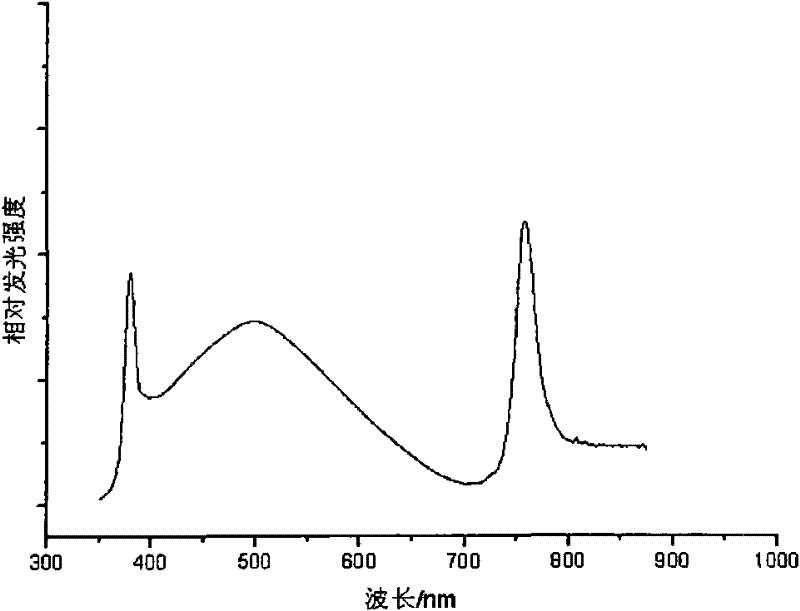

Embodiment 1

[0028] AIP---01 type multi-arc ion coating machine is adopted, and a magnetic filter device is attached to the coating machine. Both the coating machine and the magnetic filtering device can be purchased from the market, and the magnetic filtering device is manufactured by the Institute of Low Energy Nuclear Physics of Beijing Normal University; The multi-arc ion coating machine is designed and manufactured by Shenyang Kehang Surface Engineering Research and Development Center; the substrate used is quartz glass, which is relatively easy to buy from the market; the mosaic target used is a cylinder with a diameter of 100mm and a height of 45mm Three blind holes with a diameter of 12mm and a depth of 10mm are machined on the surface of the pure aluminum target surface at intervals of 120 degrees at a distance of 25mm from the center of the target surface by machining, and then pure Cr rods are embedded in them in vacuum , the hole axis is an interference fit, and finally the inla...

Embodiment 2

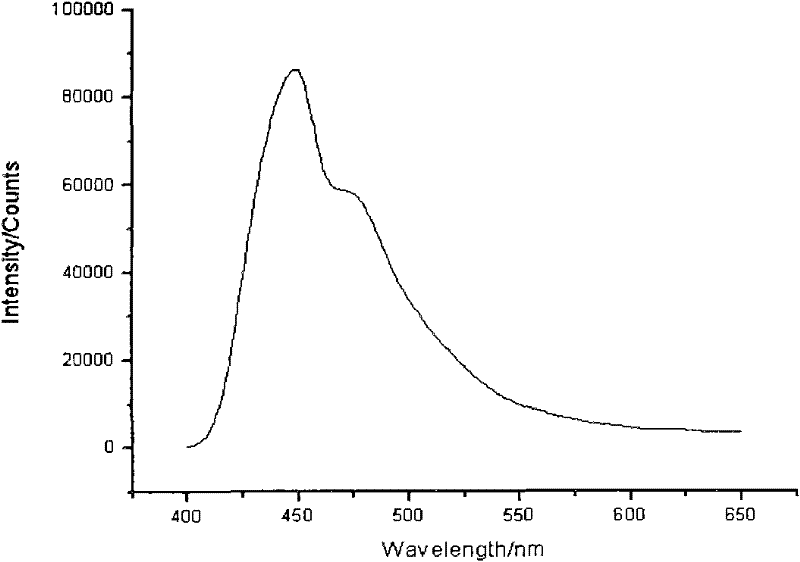

[0035]AIP---01 type multi-arc ion coating machine is adopted, and a magnetic filter device is attached to the coating machine. Both the coating machine and the magnetic filtering device can be purchased from the market, and the magnetic filtering device is manufactured by the Institute of Low Energy Nuclear Physics of Beijing Normal University; The multi-arc ion coating machine is designed and manufactured by Shenyang Kehang Surface Engineering Research and Development Center; the substrate used is quartz glass, which is relatively easy to buy from the market; the mosaic target used is cylindrical with a diameter of 100mm and a height of 45mm. On the pure aluminum target surface, three blind holes with a diameter of 14.4mm and a depth of 20mm are machined at a distance of 25mm from the center of the target surface at intervals of 120 degrees by machining, and then pure Cu rods are embedded in them in vacuum , the hole shaft is an interference fit, and finally the inlaid target ...

Embodiment 3

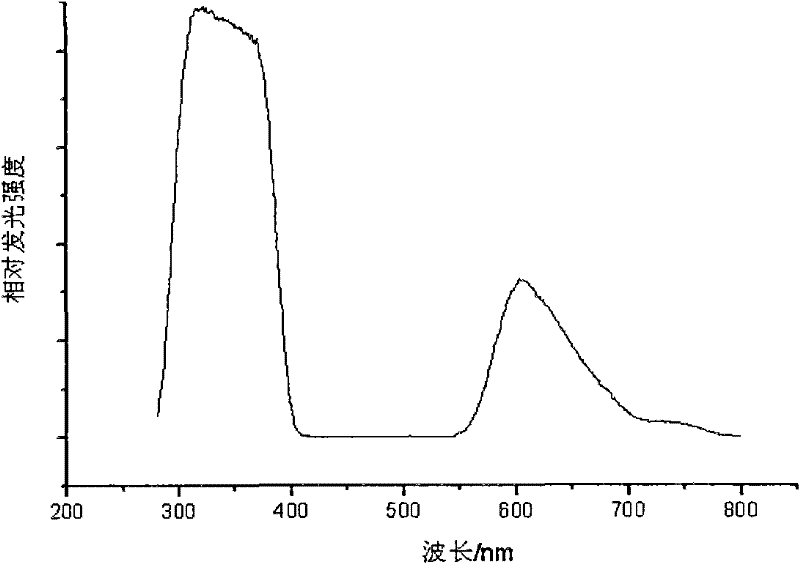

[0042] AIP---01 type multi-arc ion coating machine is adopted, and a magnetic filter device is attached to the coating machine. Both the coating machine and the magnetic filtering device can be purchased from the market, and the magnetic filtering device is manufactured by the Institute of Low Energy Nuclear Physics of Beijing Normal University; The multi-arc ion coating machine is designed and manufactured by Shenyang Kehang Surface Engineering Research and Development Center; the substrate used is N-type (100) silicon, which is relatively easy to buy from the market; the pure Cr embedded pure Al target used is in diameter On a cylindrical pure aluminum target surface with a diameter of 100mm and a height of 45mm, three blind holes with a diameter of 12mm and a depth of 10mm are machined at a distance of 25mm from the center of the target surface every 120 degrees in the radial direction by machining. The pure Cr rods are inlaid in the vacuum, and the hole axis is an interfere...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com