Film plating method for low-temperature vacuum ion plating of plastic surface

A low-temperature vacuum and ion plating technology, applied in the field of surface science and engineering, can solve the problems of high energy flux density of charged particles, inability to coat the surface of non-temperature-resistant plastics, and rapid temperature rise on the surface of workpieces. Electroless plating process, the effect of reducing technology costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The surface metallization treatment of embodiment 1 automobile ABS material accessories

[0032] Step (1), using the Hall ion source to perform ion beam sputtering cleaning on the surface of the plastic workpiece

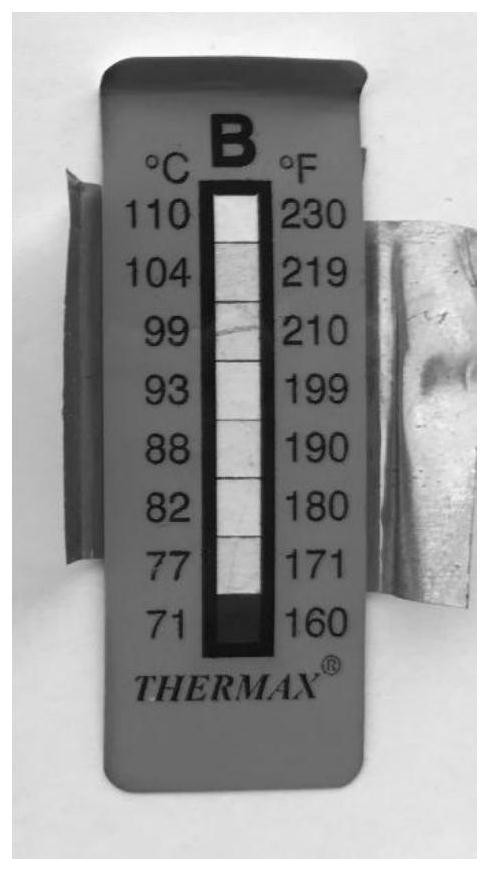

[0033] Submerge the workpiece in absolute ethanol for ultrasonic cleaning for 15 minutes, and dry the workpiece after ultrasonic cleaning for later use. The workpiece was baked in an oven at 70°C for 4 hours. The workpiece is hung on the special fixture, put into the vacuum chamber, and evacuated to a high vacuum, the vacuum degree is 5×10 - 3 Argon gas is fed at Pa, the flow rate is 50SCCM, and the vacuum degree is maintained at 5×10 -2 Pa, turn on the plasma source to clean the workpiece by sputtering. The parameters of the Hall plasma source are: voltage 500V, current 0.1A, working pressure 5×10 -2 Pa, duty cycle 10%, time 5min;

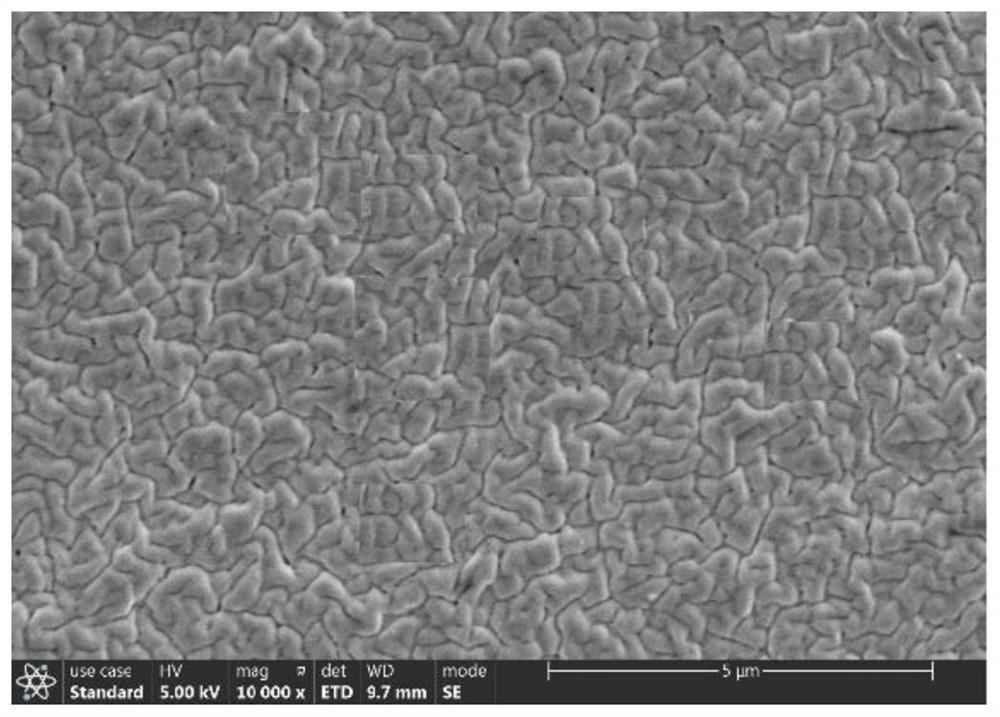

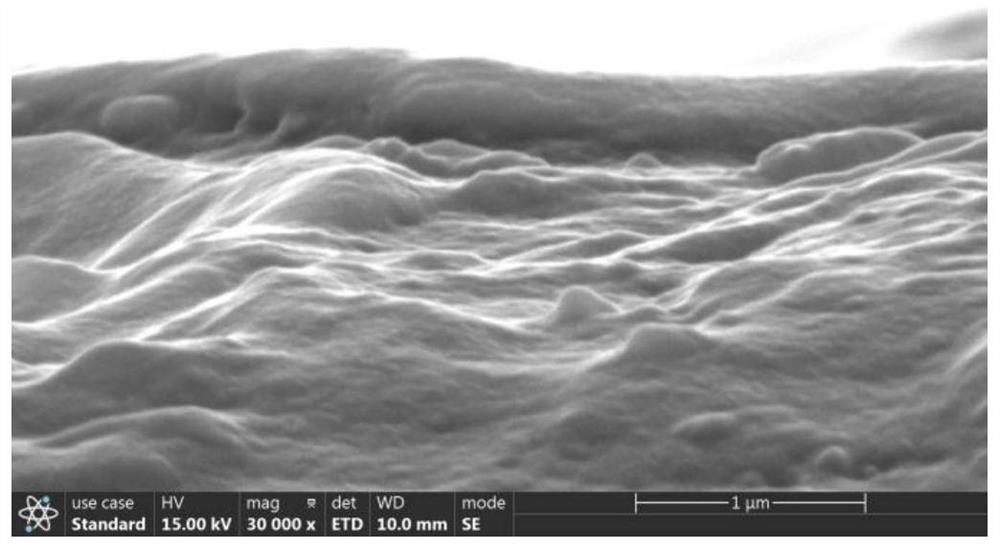

[0034] Step (2), adopt vacuum magnetic filter cathodic arc source, carry out low-temperature vacuum ion plating on the sur...

Embodiment 2

[0039] Embodiment 2 Surface metallization treatment of ABS+PC workpiece for sanitary ware hardware

[0040] Step (1), using the Hall ion source to perform ion beam sputtering cleaning on the surface of the plastic workpiece

[0041] Submerge the workpiece in absolute ethanol for ultrasonic cleaning for 15 minutes, and dry the workpiece after ultrasonic cleaning for later use. The workpiece was baked in an oven at 70°C for 4 hours. The workpiece is hung on the special fixture, put into the vacuum chamber, and evacuated to a high vacuum, the vacuum degree is 5×10 - 3 At Pa, the mixed gas of argon and nitrogen is sent, the ratio is 1:1, the flow rate is 45SCCM, and the vacuum degree is maintained at 5×10 -1 Pa, turn on the plasma source to sputter clean the workpiece. The parameters of the Hall plasma source are: voltage 1800V, current 3A, working pressure 5×10 -1 Pa, duty cycle 10%, time 30min;

[0042] Step (2), adopt vacuum magnetic filter cathodic arc source, carry out l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com