Material group distribution detection and regulation system and method in variable-ellipse equal-thickness screening process

A distributed detection and control system technology, applied in chemical instruments and methods, filtration, solid separation, etc., can solve the problem of difficult to achieve equal thickness and high-efficiency screening of material groups, failure to achieve real-time control of excitation parameters, and failure to achieve screen surface Problems such as real-time online monitoring of the spatial distribution of the movement track material group, etc., to achieve the effect of good screening effect, real-time and accurate detection, and large processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

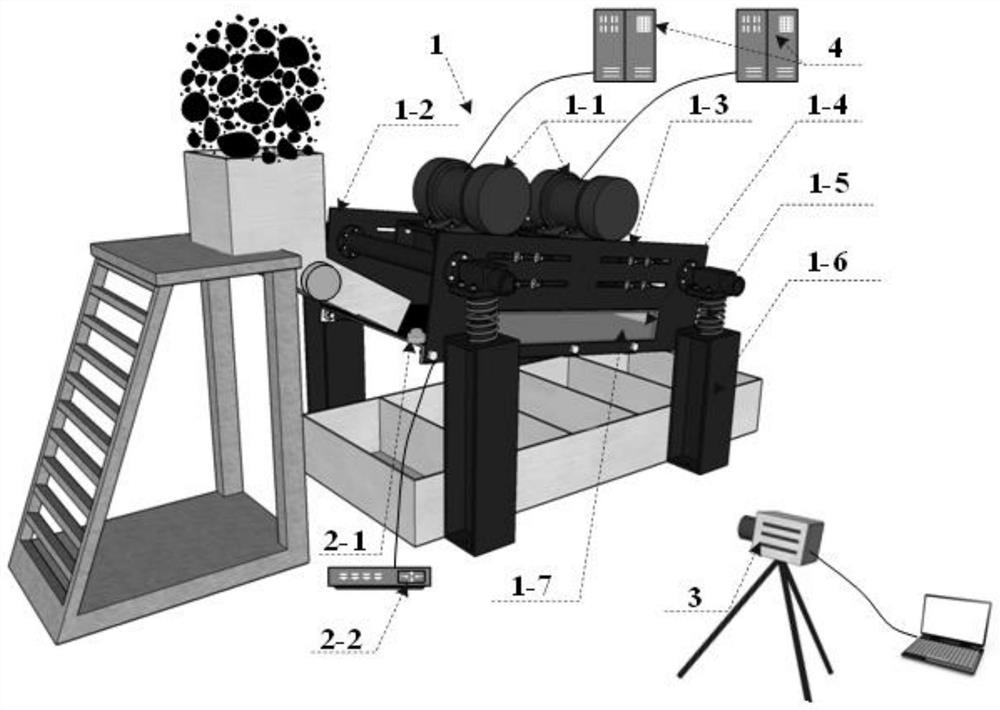

[0023] Such as figure 1 As shown, the present invention provides a system for detecting and controlling the distribution of material groups in the variable ellipse and equal thickness screening process, including a variable ellipse and equal thickness sieve 1, a vibration test and analysis device for the screen surface, a high-speed camera test and analysis device for the material group, and a vibration excitation device. Control device 4;

[0024] The variable ellipse equal thickness screen 1 includes a screen box body 1-2, a damping spring 1-5 and a bottom support 1-6, and the screen box body 1-2 includes two oppositely arranged screen box side plates 1- 3 and the screen surface 1-4, the upper part and the bottom between the two screen box side plates 1-3 are respectively equipped with an excitation beam and a load-bearing beam, and an unbalanced vib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com