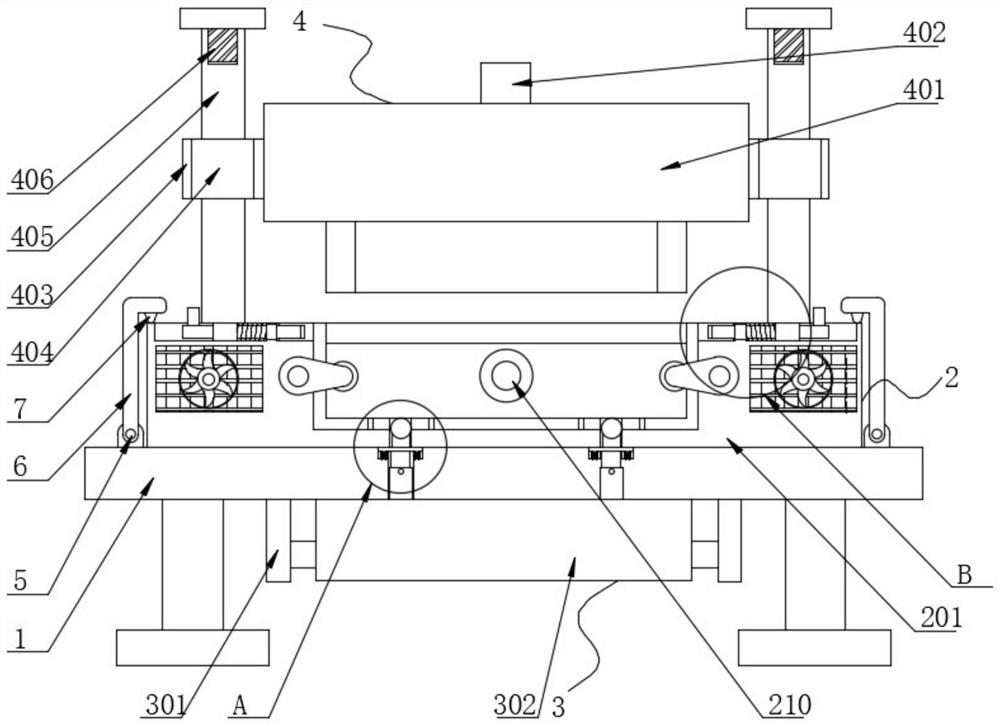

Hardware part machining die with discharging mechanism

A discharging mechanism and mold processing technology, which is applied in the field of hardware processing, can solve the problems of lack of mold release means and complexity of molds, and achieve the effects of shortening cooling time, reducing the difficulty of discharging, and improving the efficiency of discharging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

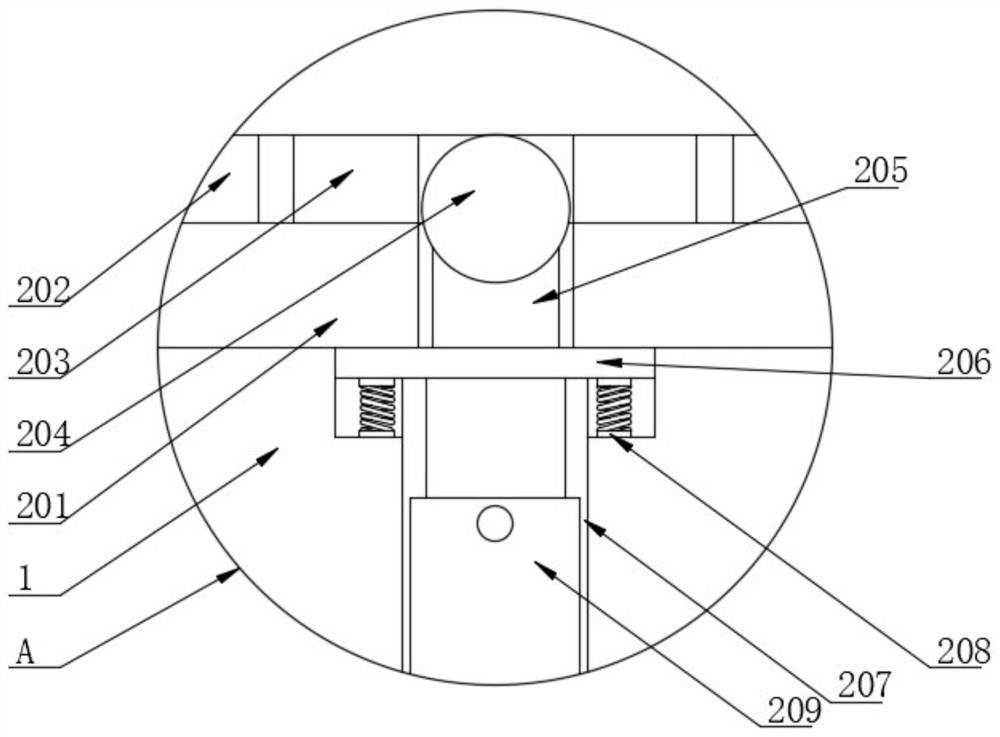

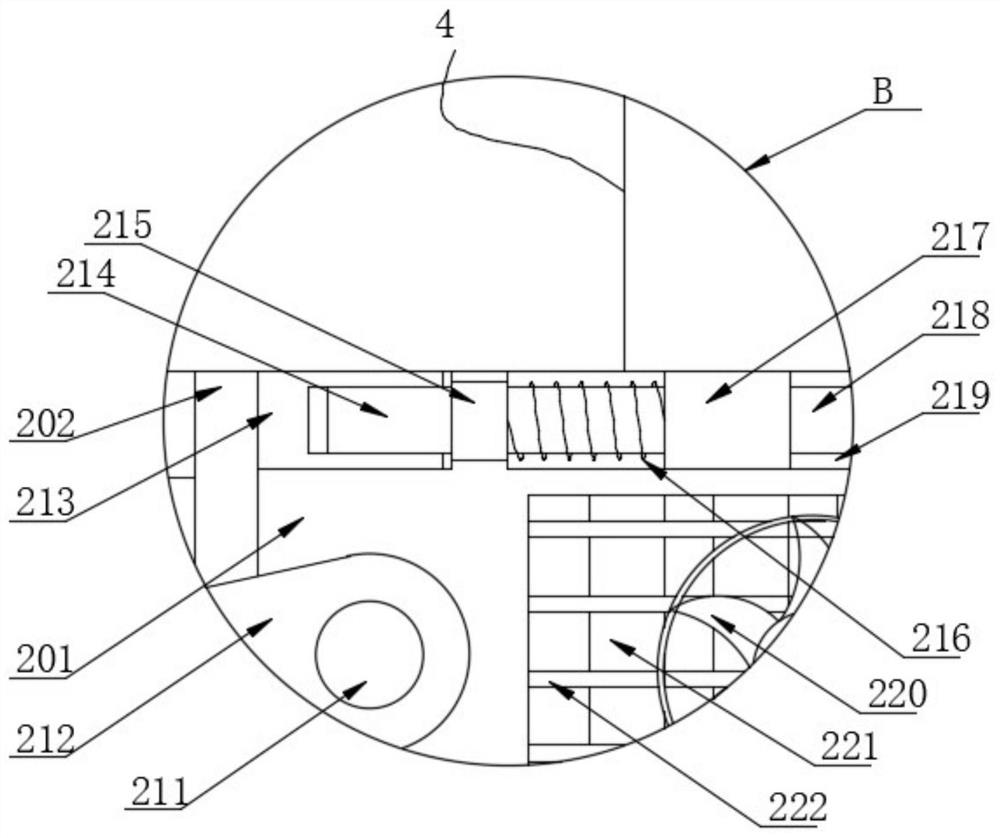

[0046] The implementation method is as follows: After the lower mold base 202 is snapped into the fixed base 201, the stamping hardware is placed on the top of the fixed base 201, and the upper transmission rod 402 drives the upper mold base 401 and the second sliding sleeves 404 on both sides on the second sliding rod. 405 slides outside, and the upper mold base 401 moves downward to contact the stamping hardware with the lower mold base 202. After the stamping contacts, the object is stamped and limited in the lower mold base 202 of the limit seat, and passes through by twisting the limit plates 212 on both sides. The pin shaft 211 is separated from the lower mold base 202, and the limit plate 212 can limit and support the lower mold base 202 during stamping, avoid shaking, improve overall safety, and control the external oil circuit switch to control the hydraulic cylinders 209 on both sides of the bottom. The hydraulic rod is extended, and the hydraulic rod of the hydraulic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com