A kind of screw grinding machine

A screw and tooth machine technology, applied in the direction of threaded products, solid separation, liquid cleaning methods, etc., can solve the problems of difficult waste cleaning, time-consuming and laborious cleaning, etc., achieve liquid recycling and collect waste, reduce difficulty, Efficient waste collection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

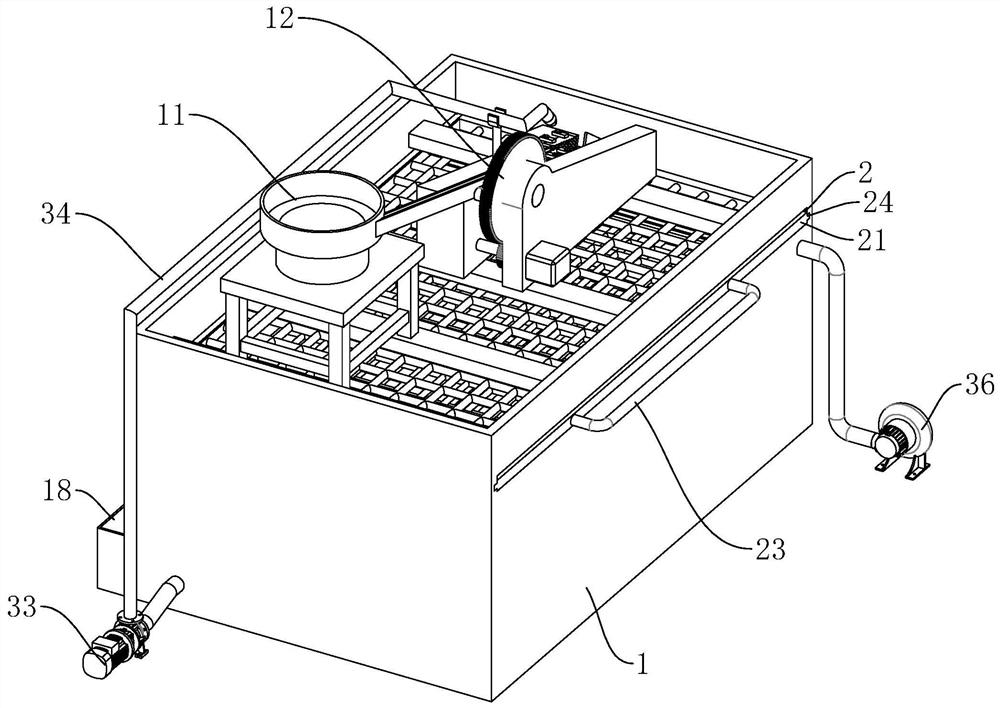

[0037] The following is combined with the attached Figure 1-6 Further elaboration of this application.

[0038] Embodiments of the present application disclose a screw grappling machine. Reference Figure 1 and Figure 2 , a screw rubbing machine comprises a body 1, a feeding mechanism 11 for screw blank feeding and a dental rubbing mechanism 12 for the screw blank conveyed by the feeding mechanism 11. The top opening of the body 1 and the cavity inside, the feeding mechanism 11 and the rubbing mechanism 12 are fixed sequentially in the direction of the length of the body 1 at the top opening of the body 1. On the outer wall of the side of the body 1 is opened along its length 2, the first chute 2 is provided with a screw filter 21 for filtering debris, the screw filter 21 is located under the rubbing mechanism 12 and the feeding mechanism 11. The body 1 is provided with a recycling mechanism 3 for recycling waste materials, the recycling mechanism 3 is located under the screw filte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com