Filtering and conveying all-in-one machine for grain processing

An all-in-one machine and grain technology, applied in the field of grain processing, can solve the problems of multi-time and cost, consumption, affecting the progress of processing, etc., and achieve the effect of convenient storage and delivery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

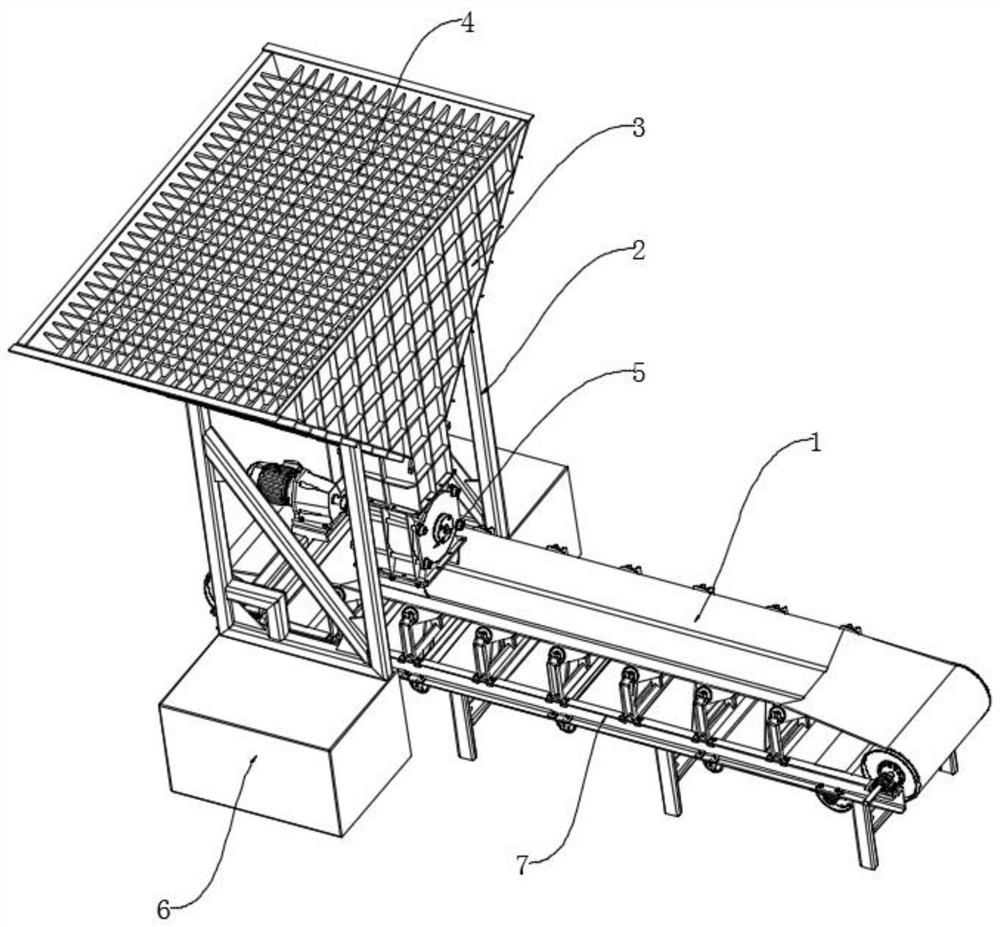

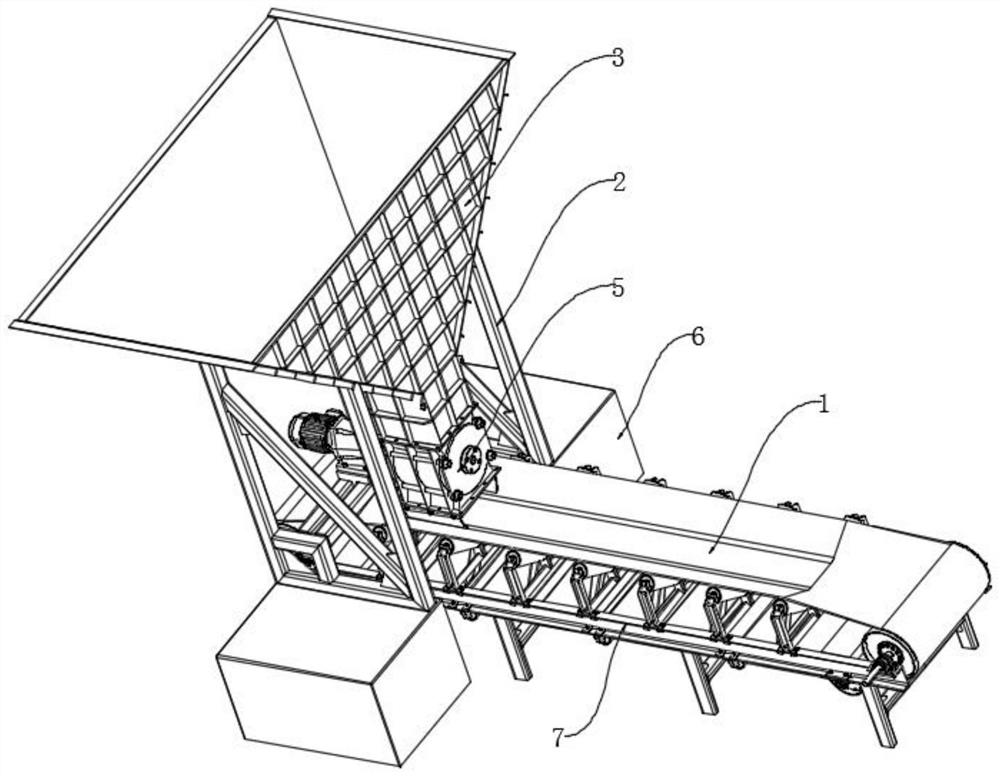

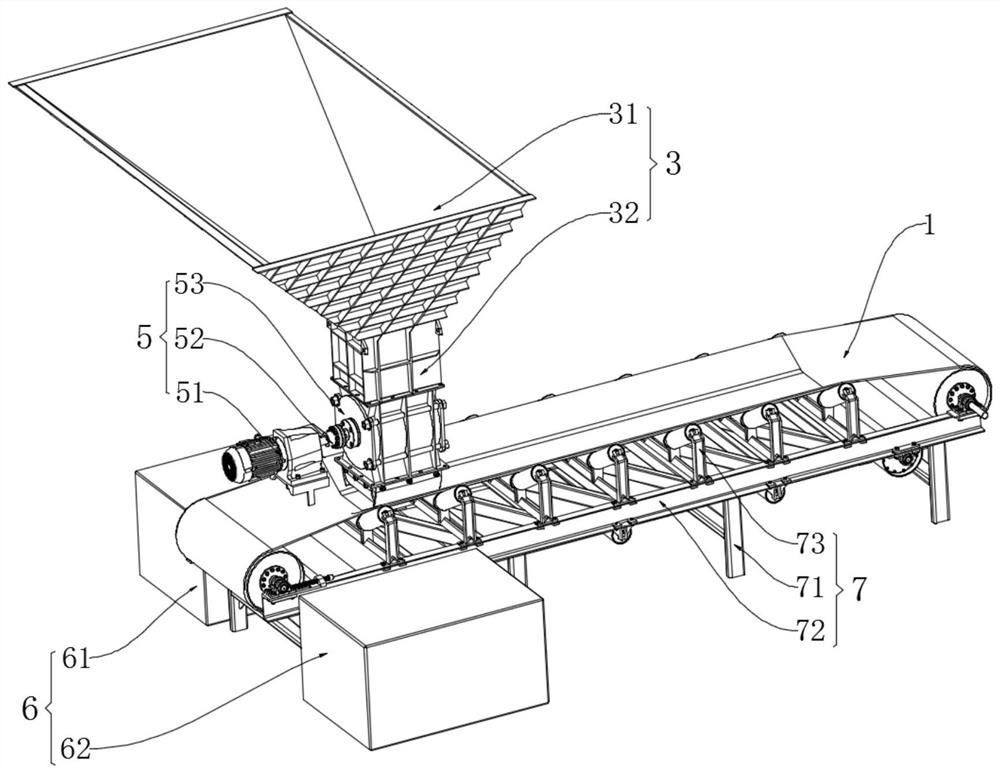

[0034] see Figure 1-7 , the present embodiment provides an integrated filtering and conveying machine for grain processing, including: a support assembly 7, and a crawler belt 1 is arranged on the outside of the support assembly 7;

[0035] A support assembly 6, the support assembly 6 is arranged on the side of the support assembly 7;

[0036] Support frame 2, the bottom of the support frame 2 is connected with the support assembly 6;

[0037] A funnel assembly 3, the side of the funnel assembly 3 is connected to the top of the support frame 2, and the funnel assembly 3 is provided with a filter screen 4;

[0038] Stirring component 5, said stirring component 5 is arranged on said funnel component 3.

[0039] In the all-in-one filtering and conveying machine for grain processing provided in this embodiment, the funnel assembly 3 includes a feeding hopper 31 and a material guiding cylinder 32, the top of the material guiding cylinder 32 is connected to the feeding hopper 31,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com