Preparation method of self-repairing material and self-repairing film layer on surface of matrix

A self-healing material and film technology, applied in coatings, anti-corrosion coatings, etc., can solve problems such as damage and loss of protection performance, achieve the effects of wide sources, improve corrosion protection performance, and solve external stimulus responsiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

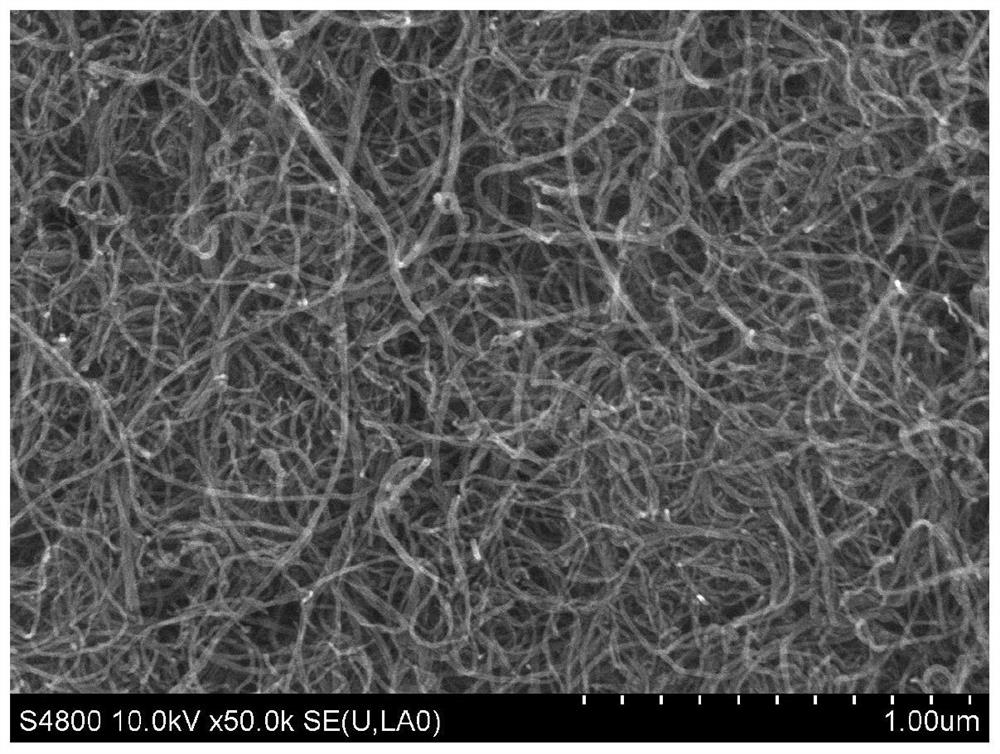

[0023]Choose nano-scale nanotubes (carbon nanotubes), the scanning electron microscope photos are asfigure 1 As shown, it can be seen that the carbon nanotubes are distributed in nano-scale bundles.

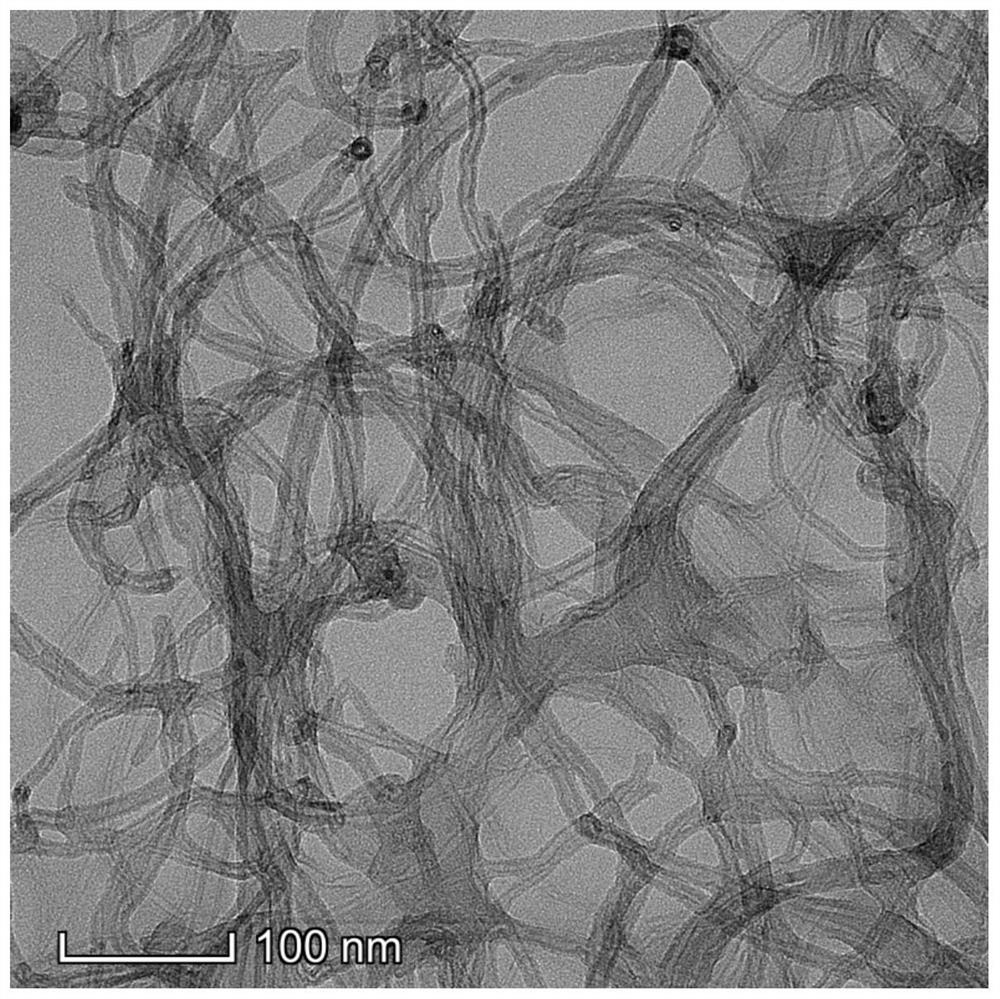

[0024]Disperse the nanoscale carbon nanotubes into silicone oil, stir at 25°C for 25 minutes, and then ultrasonically disperse at 60°C for 60 minutes. During the ultrasonic process, vacuum is applied to remove the air at the interface between carbon nanotubes and silicone oil to obtain a mixed material. The solid-phase nanotubes in the material are uniformly dispersed in the liquid phase without agglomeration. The TEM photo of the mixed material is asfigure 2 As shown, it is explained that the solid-phase carbon nanotubes form a cross-linked network structure in the liquid phase after simple dispersion.

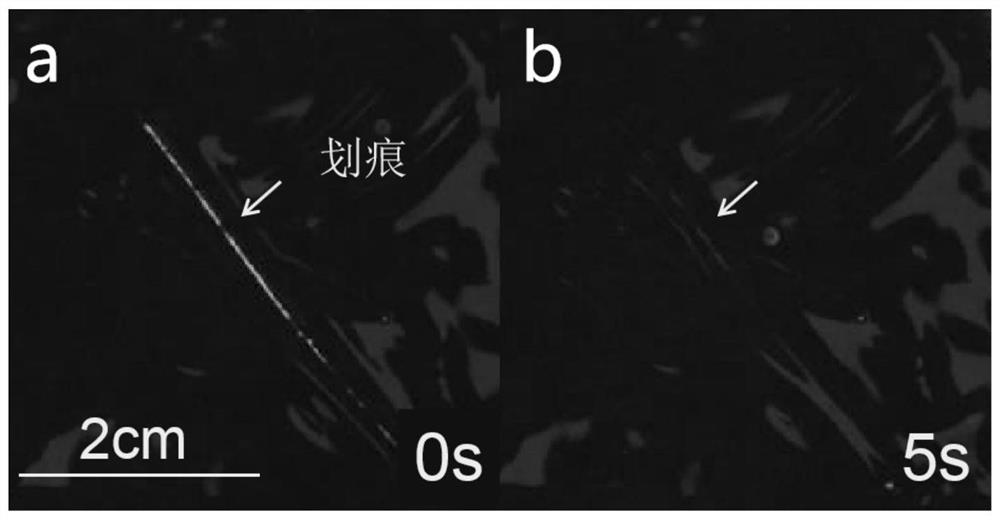

[0025]The above-mentioned mixed material is coated on a metal substrate to form a film layer. Then likeimage 3 As shown in the figure (a), the film is scratched to form a scratch, even if t...

Embodiment 2

[0033]Disperse micro-nano fibers (glass fibers) into the liquid-phase material silicone resin, stir at 15°C for 50 minutes, and then ultrasonically vibrate at 60°C for 45 minutes. During the ultrasonic process, vacuum remove the glass fiber and silicone resin interface. Air is used to obtain a mixed material in which solid phase particles are uniformly dispersed in the liquid phase without agglomeration. The transmission electron micrograph of the mixed material shows that the solid phase particles form an interleaved cross-linked structure in the liquid phase after dispersion.

[0034]The above-mentioned mixed material is coated on a metal substrate to form a film layer. Then, the film is scratched to form a scratch. Even if the width of the scratch reaches the millimeter level, the scratch has been basically repaired after 5 seconds, indicating that the film has rapid self-healing ability.

[0035]Similar to Example 1, the film layer prepared above was immersed in 1mol / L salt water for ...

Embodiment 3

[0037]Disperse the micro / nanorods (clay attapulgite) into the liquid phase material silane, stir at 30°C for 40 minutes, and then ultrasonically vibrate at 45°C for 65 minutes. During the ultrasonic process, vacuum is applied to remove the air at the interface between the clay attapulgite and silane. A mixed material is obtained in which the solid phase particles are uniformly dispersed in the liquid phase without agglomeration. The transmission electron micrograph of the mixed material shows that the solid phase particles form a cross-linked labyrinth structure in the liquid phase after dispersion.

[0038]The above-mentioned mixed material is coated on a metal substrate to form a film layer. Then, the film is scratched to form a scratch. Even if the width of the scratch reaches the millimeter level, after about 7 seconds, the scratch has been basically repaired, indicating that the film has rapid self-healing ability.

[0039]Similar to Example 1, the film layer prepared above was immer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com