Double-row leather collar yarn guide assembly of ring spinning frame and ring spinning frame

A spinning frame and apron technology, applied in the field of spinning, can solve problems such as the influence of installation error and transmission deviation on spinning index, increased difficulty of installation and replacement, and complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

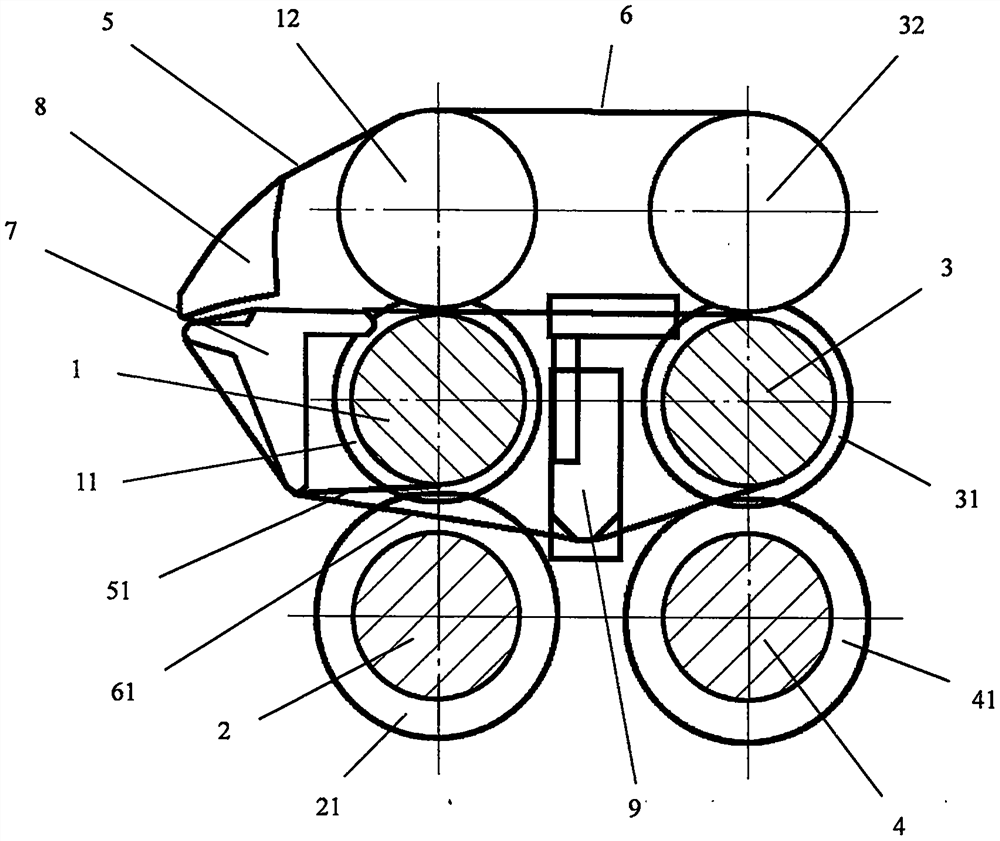

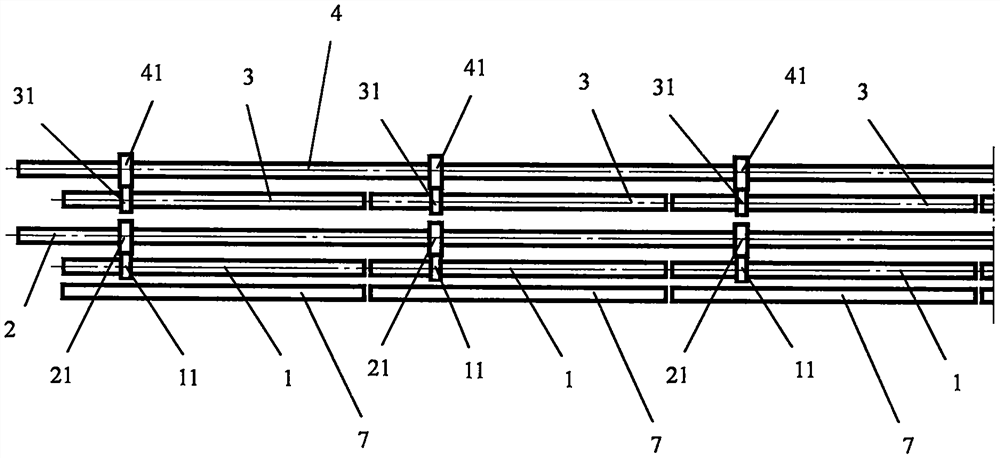

[0018] Such as figure 1 As shown, the cross-sectional schematic diagram of the double-row apron yarn delivery assembly of the ring spinning machine, the assembly includes a middle roller 1, a middle top roller 12, a middle roller transmission shaft 2, a middle roller transmission gear 21, a rear roller 3, Rear upper roller 32, rear roller transmission shaft 4, rear roller transmission gear 41, middle upper apron 5, middle lower apron 51, rear upper apron 6, rear lower apron 61, lower shaft 7, upper shaft 8, rear lower apron Ring tension frame 9, middle upper apron 5 is set on middle upper roller 12 and upper roller 8, middle and lower apron 51 is set on lower roller 7 and middle roller 1, rear upper apron 6 spans middle upper roller 12 and is set on rear upper Roller 32 and upper roller 8, and rear lower apron 61 straddle middle roller 1 and set on lower roller 7 and rear roller 3, and are tightened by the action of lower apron tension frame 9, and the middle upper apron 5 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com