Water-proof, oil-proof, antifouling and mite-proof textile and preparation method and application thereof

A waterproof and oil-proof, textile technology, applied in the field of textiles, can solve the problems of poor effect, waterproof, oil-proof, anti-fouling and anti-mite can not have both at the same time, to prevent water infiltration and oil contamination, good waterproof, oil-proof and anti-mite. The effect of pollution performance and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

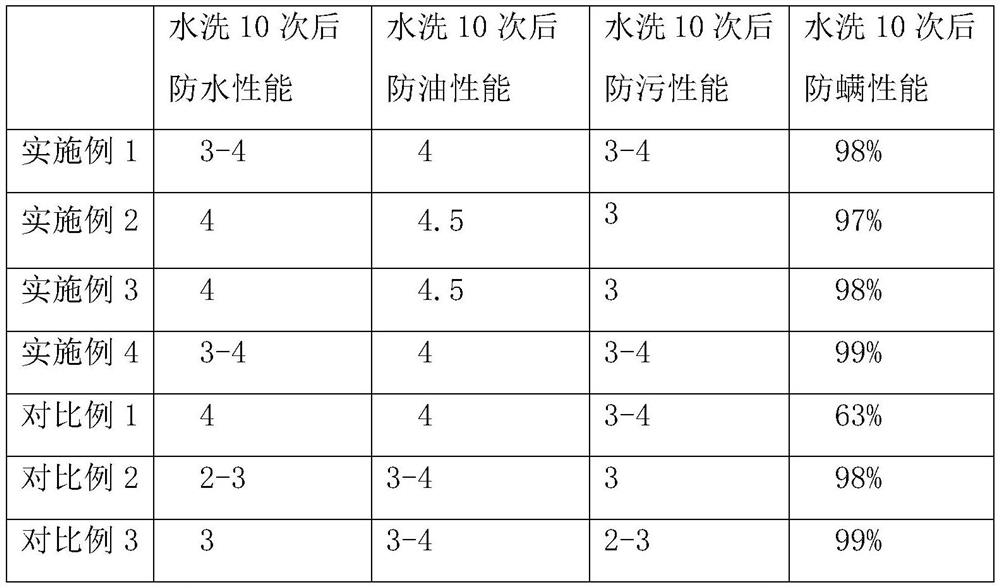

Examples

preparation example Construction

[0039] The preparation method of waterproof, oil-proof, stain-proof and anti-mite textiles in the embodiment of the present application is characterized in that it includes: finishing the high-count and high-density gray cloth after refining or desizing, and the finishing process includes cleaning, waterproof and anti-mite in sequence. Oil and anti-fouling finishing and calendering treatment; the cleaning process refers to the use of cleaning agents to treat the refined or desized high-count and high-density gray cloth; Rolling treatment, and then drying for setting.

[0040] Specifically, the high-count and high-density gray cloth is made of high-count yarns, warped in sections to make weaving beams, and the high-count and high-density gray cloth is produced on a shuttle loom.

[0041] Specifically, the yarn in the gray cloth is one or more selected from polyester or cotton.

Embodiment 1

[0043] In this embodiment, the gray cloth is formed of polyester yarns, the linear density of the polyester yarns used in the gray cloth is 60D, and the warp and weft density of the gray cloth is 300.

[0044] The cleaning solution in this embodiment includes 2 parts of cleaning agent and 98 parts of water. The cleaning agent is the cleaning agent SCOURIN SB-5F of Shanghai Zhanhe Industry.

[0045]The three-proof treatment liquid includes: 7 parts of three-proof finishing agent, 3 parts of synergist and 100 parts of water. Acetic acid is used to keep the pH of the three-proof treatment solution at 4-6. The three anti-finishing agent is AFH6 selected from Rudolf Company. The synergist is an adhesive selected from Jiangsu Xinruibei Technology HX.

[0046] In the waterproof, oil-proof and anti-fouling treatment, when padding, one dipping and one rolling are adopted, the liquid carrying rate is 40%, and the speed is 50m / min.

[0047] In the water-proof, oil-proof and anti-fo...

Embodiment 2

[0050] In this embodiment, the gray cloth is formed of cotton yarn, the count of the cotton yarn used in the gray cloth is 100S, and the warp and weft density of the gray cloth is 300.

[0051] The cleaning solution in this embodiment includes 5 parts of cleaning agent and 95 parts of water. The cleaning agent is the cleaning agent SCOURIN SB-5F of Shanghai Zhanhe Industry.

[0052] The three-proof treatment liquid includes: 10 parts of three-proof finishing agent, 1 part of synergist and 100 parts of water. Acetic acid is used to keep the pH of the three-proof treatment solution at 4-6. The three-proof finishing agent is DuPont's Teflon SLA. The synergist is the water-dispersed isocyanate crosslinking agent EC-600 of Shanghai Sisheng polymer material.

[0053] In the water-proof, oil-proof and anti-fouling treatment, when padding, one dipping and one rolling are adopted, the liquid carrying rate is 50%, and the vehicle speed is 50m / min.

[0054] In the water-proof, oil-pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com