Air-spaced explosive charging structure and air-spaced explosive charging method

An air spacer and charge technology, which is applied in the field of blasting test, can solve the problems of high price of ordinary air spacers, increase the time of shock wave action, reduce the peak pressure of detonation wave, etc., so as to improve the blasting effect, increase the action time of shock wave and blast low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

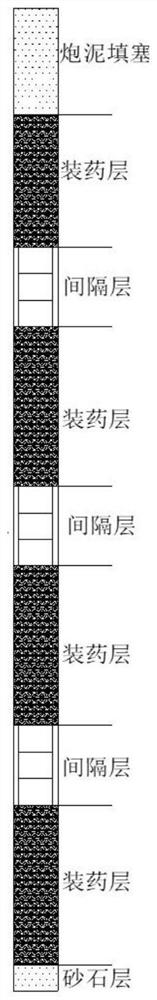

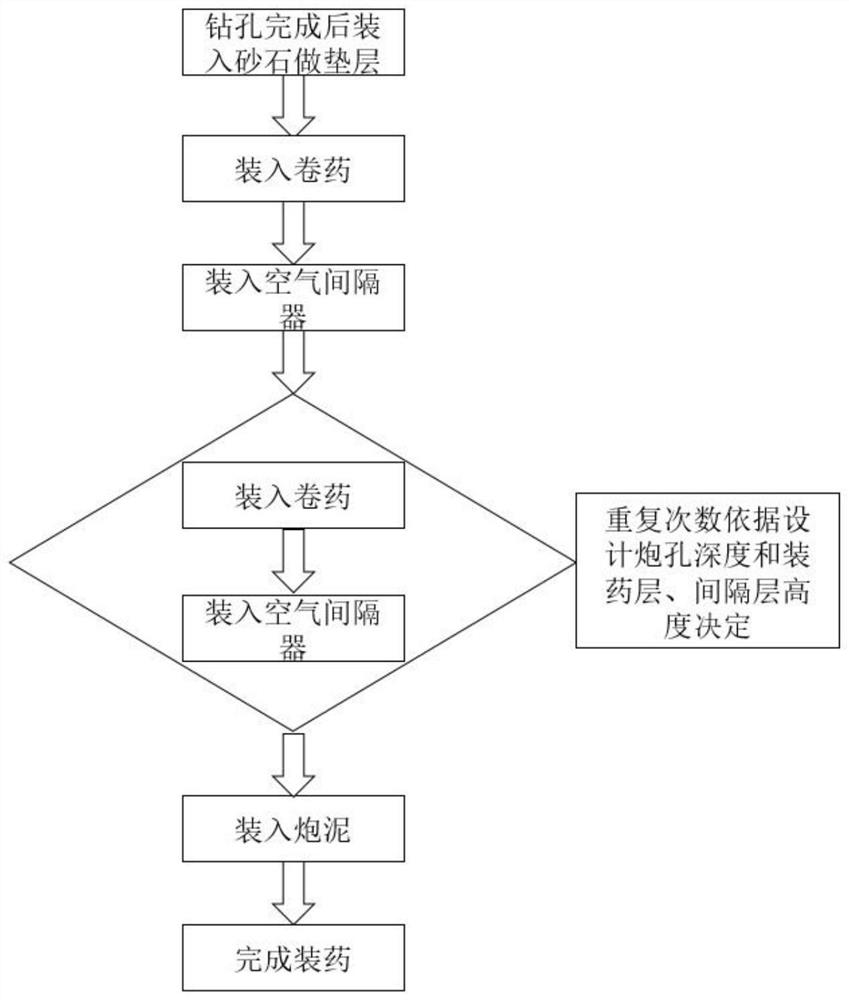

[0039] Embodiment 1: as figure 1 As shown, an air-spaced charge structure,

[0040] Including the sandstone layer, the sandstone layer is set at the bottom of the blast hole;

[0041] Several layers of charge layers and several layers of spacer layers, the charge layers and spacer layers are arranged alternately, the top of the sandstone layer is provided with charge layers, and the spacer layer is a water bottle air spacer;

[0042] A gun port protector arranged at the gun port;

[0043] A blasting mud packing layer, where the blasting mud packing layer is packed in the blast hole protector of the blast hole;

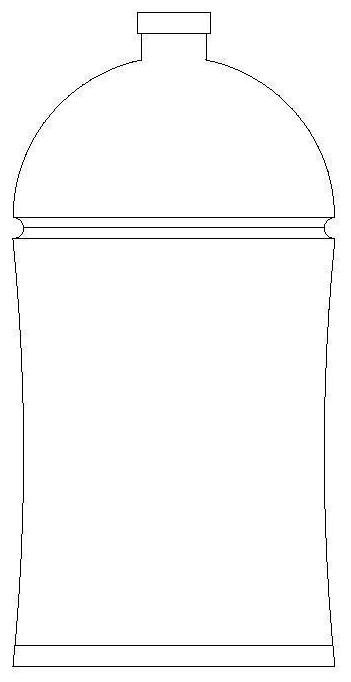

[0044] The water bottle air spacer includes more than two water bottles and elastic buckles;

[0045] Such as image 3 and 5 As shown, the water bottle air spacer in this embodiment is two water bottles, and the two water bottles are respectively water bottle I and water bottle II. The mouths of water bottle I and water bottle II are opposite and connected by elas...

Embodiment 2

[0054] Embodiment 2: The air-spaced charge structure of this embodiment is basically the same as the air-spaced charge structure of Example 1, the difference is that: the water bottle air spacer is three water bottles, and the three water bottles are respectively water bottle I, water bottle II and water bottle For water bottle III, the mouths of water bottle I and water bottle II are opposite and connected by elastic buckles. The bottom is connected to the upper charge layer (see Figure 6 ).

Embodiment 3

[0055]Embodiment 3: The air-spaced charge structure of this embodiment is basically the same as the air-spaced charge structure of Example 1, the difference being that the water bottle air spacer is four water bottles, and the four water bottles are respectively water bottle I, water bottle II, Water bottle III and water bottle IV, the mouths of water bottle I and water bottle II face each other and are connected by elastic buckles, the bottom of water bottle I connects with the lower charge layer, and the mouths of water bottle III and water bottle IV face each other and are connected by elastic buckles , the bottom of the bottle of water bottle III joins with the bottom of the bottle of water bottle II, and the bottom of the bottle of water bottle IV joins with the upper charge layer (see Figure 7 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com