Rapid positioning and roundness detection method for circle center of circular hole of aeronautical part

A detection method and circular hole technology, which are applied in image data processing, instruments, calculations, etc., can solve the problems of high cost, low manual measurement efficiency, poor accuracy, etc., and achieve the goal of reducing resource requirements, saving computer memory, and reducing computing time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

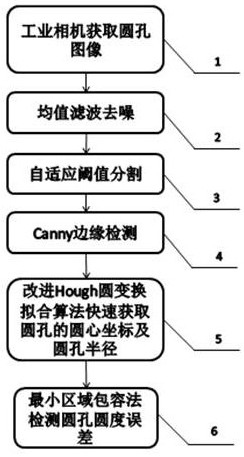

[0031] A method for detecting a round hole of an aviation part according to the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

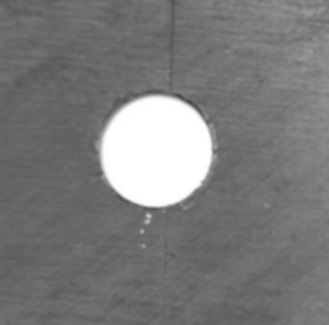

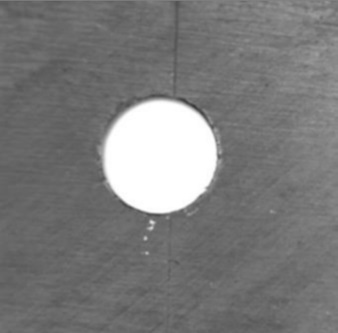

[0032] Step 1: Use the original round hole image captured by the CMOS industrial camera to collect the image through the image acquisition card and transmit it to the industrial computer. After the camera captures the round hole image, the acquisition card compresses the analog signal of the original round hole image into a digital signal recognized by the computer transferred to computer memory, such as figure 2 Shown is a camera image of a hole displayed on a computer screen.

[0033] Step 2: In the process of image acquisition, various noises will be introduced due to the influence of sensor material properties and working environment, which will reduce the image quality of the round hole image and further affect the acquisition of image edge information to varyi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com