A smooth running pasta machine

A pasta machine and machine base technology, applied in kitchen utensils, home utensils, applications, etc., can solve the problems of large gap error between screw and extrusion cylinder, mechanical danger, uneven extrusion speed, etc., and achieve local structural strength enhancement. , The effect of force balance and stability, prolonging the overall life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

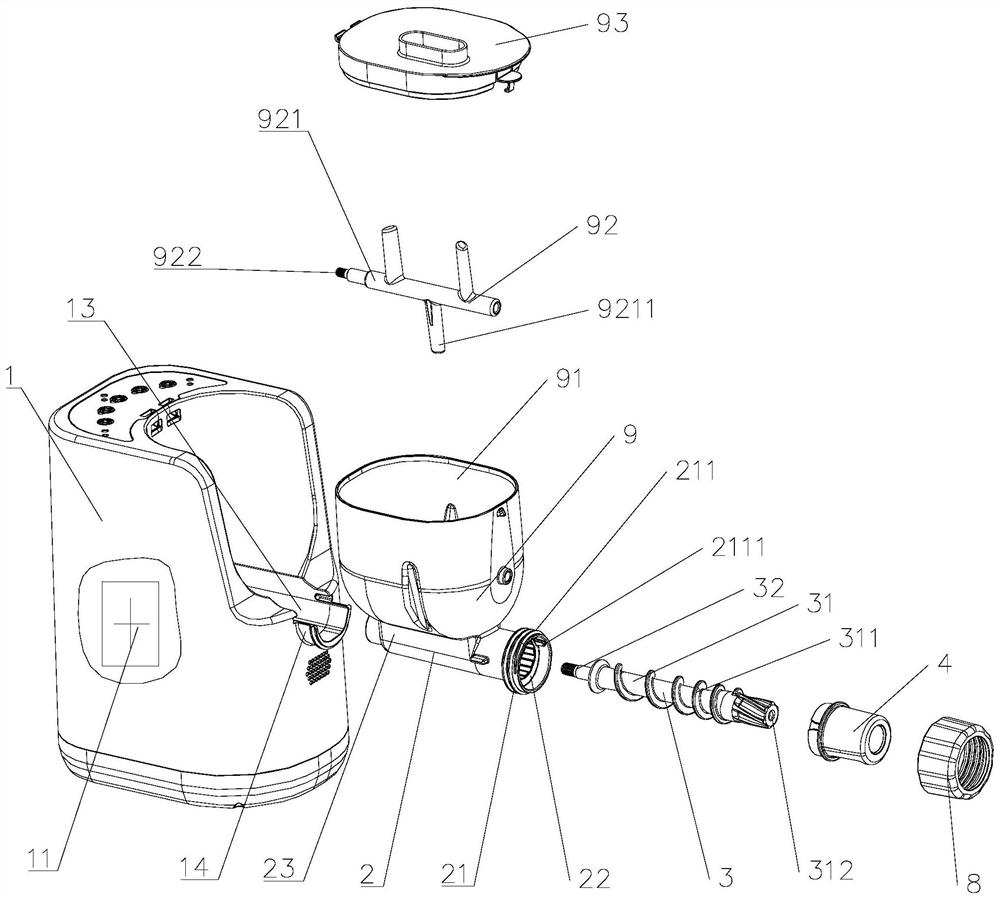

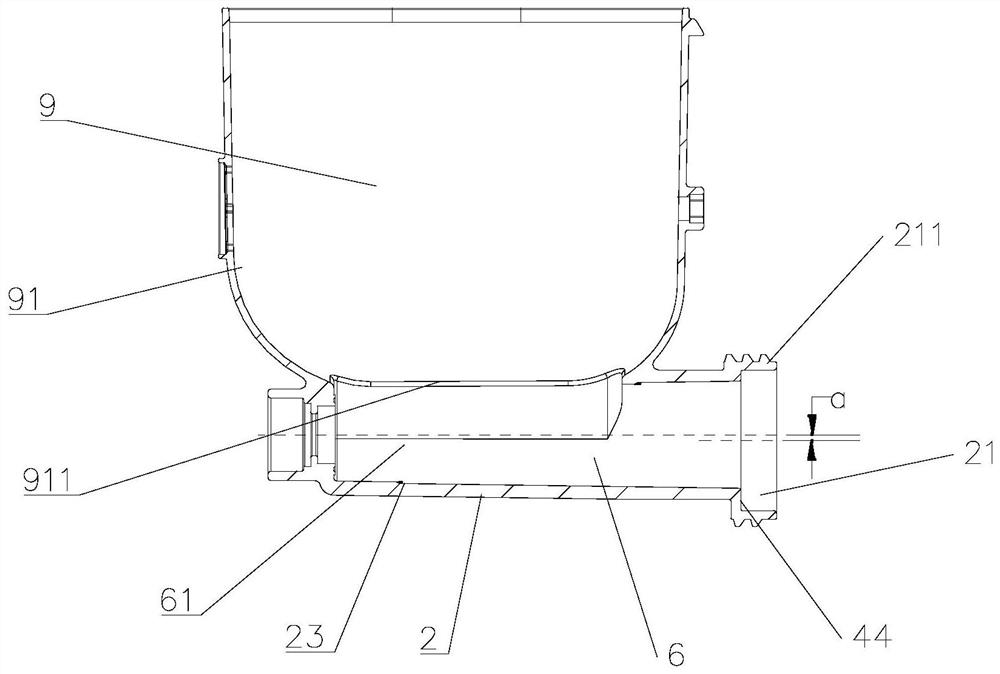

[0045] Such as Figure 1 to Figure 4 Shown, a kind of pasta machine that runs smoothly, comprises machine base 1, is arranged on the stirring assembly 9 and extruding assembly on the machine base, is provided with motor 11 in the machine base, and described stirring assembly 9 comprises stirring cup 91, is arranged on The stirring rod 92 in the stirring cup is covered with the upper cover 93 of the upper port of the stirring cup. The stirring rod includes a rod body 921 and a rod shaft 922. The rod body is provided with stirring teeth 9211. The extruding assembly includes an extruding cylinder 2 , the screw rod 3 horizontally arranged in the extrusion barrel, the die head assembly arranged at the front end of the extrusion barrel, the screw 3 includes a screw body 31 and a screw shaft 32, and the screw body is provided with a screw 311, the stirring cup and the extrusion surface The barrel is connected and set through the noodle inlet 911, the noodle inlet 911 is set at the bo...

Embodiment 2

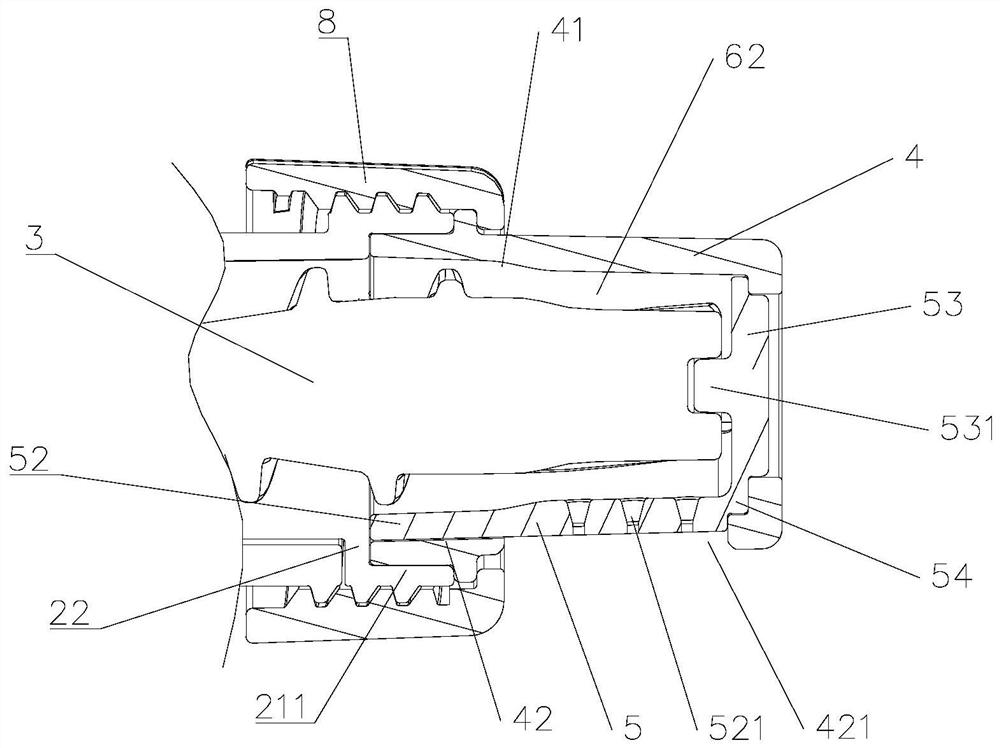

[0069] Such as Figure 5 to Figure 7 As shown, the difference between the present embodiment and the first embodiment is that the pop-up device is not provided between the screw rod 3 and the output shaft of the motor, and the pasta machine is provided with an in-position detection device of the die head, and the in-position detection device avoids mold If the head 5 is missing, the food machine will start by mistake, and at the same time, the risk of the user's fingers touching the screw and other moving parts is avoided.

[0070] In the present embodiment, the pasta machine includes a machine base 1 with a motor, a stirring assembly 9 connected to the machine base 1 and an extruding assembly. The upper cover 93 of the upper port of the mixing cup, the extruding assembly includes an extruding barrel 2, a screw 3 arranged transversely in the extruding barrel, and a die assembly arranged at the front end of the extruding barrel, and the die assembly includes a die Support 4 an...

Embodiment 3

[0078] The difference between this embodiment and the second embodiment lies in that the structure of the die head assembly is different.

[0079] In this embodiment, the die head is provided with a forming hole, and the die head is covered with the front port of the sleeve, so as to realize front-facing. Specifically, the die head includes an end face and an arc-shaped side wall connected to the edge of the end face, a forming hole is provided on the end face, the die head extends into the sleeve through the arc-shaped side wall, and the arc-shaped side wall and the inner wall of the cylinder Smooth connection. The second eccentric part includes the inner peripheral surface of the arc-shaped side wall of the die head, and the inner peripheral surface is not concentrically arranged with the outer peripheral surface of the die head support, so that the inner peripheral surface is smoothly connected with the inner wall of the extrusion cylinder to form a concentric Material tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com