Intelligent chemical coating spraying device

A spraying device and coating technology, applied in the direction of spraying devices, liquid spraying devices, etc., can solve the problems of small workpiece spraying, cumbersome steps, inconvenient operation and inability to achieve convenient spraying, improve spraying quality, and save maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

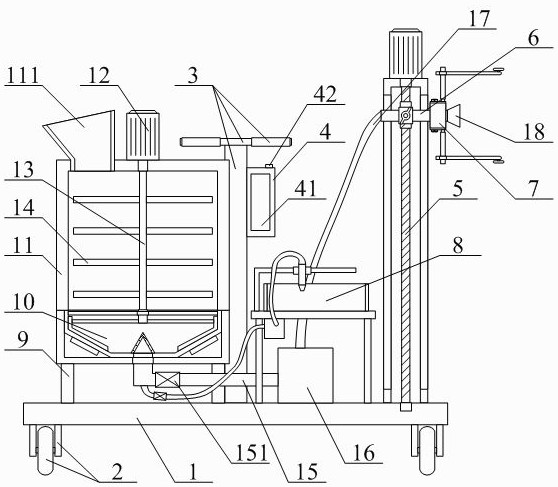

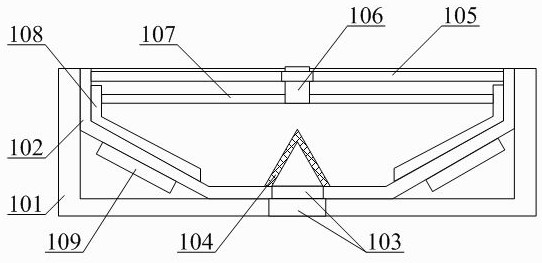

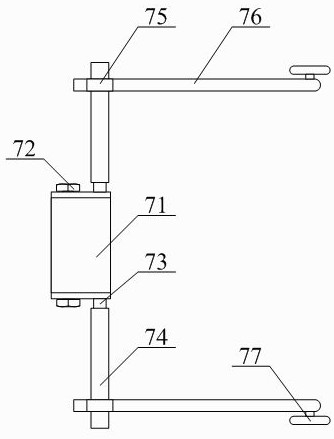

[0041] as attached figure 1 And attached figure 2 As shown, an intelligent chemical paint spraying device includes a frame 1, a moving wheel 2, a moving push handle 3, a control box 4, a mobile lifting spraying frame structure 5, a sliding connecting pipe 6, a manual spraying positioning frame structure 7, and a small Parts spray frame structure 8, bracket 9, heating and mixing discharge seat structure 10, box body 11, mixing motor 12, rotating shaft 13, stirring blade 14, discharge pipe 15, large suction pump 16, connecting hose 17 and spraying Head 18, the moving wheels 2 are respectively bolted to the four corners of the bottom of the frame 1; the moving pusher 3 is welded to the upper rear end of the frame 1; The right side; the mobile lifting spray frame structure 5 is installed on the upper right side of the frame 1; the sliding connecting pipe 6 is arranged on the inside of the mobile lifting spray frame structure 5; the manual spray positioning frame structure 7 is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com