Efficient dicing device for poria cocos pretreatment

A technology for pre-processing and dicing, which is applied to the field of high-efficiency dicing devices for pre-processing Poria cocos, can solve problems such as low efficiency and labor consumption, and achieve the effects of reducing radial force, high dicing efficiency, and improving processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

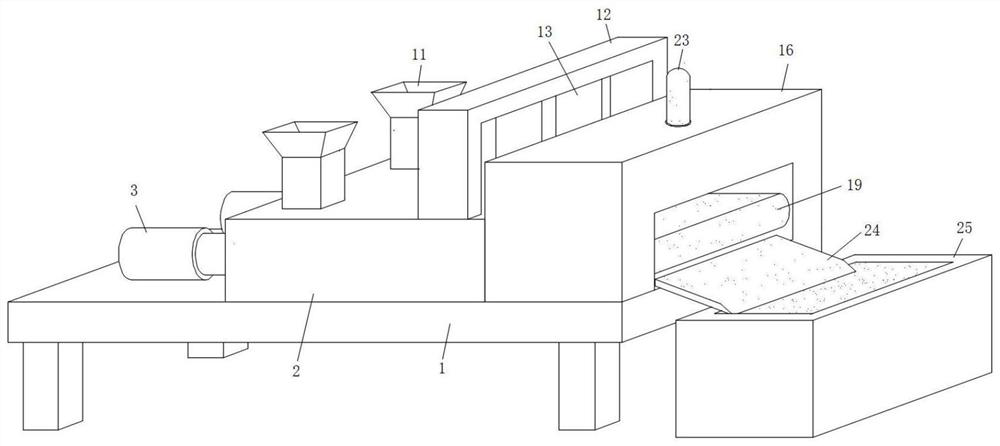

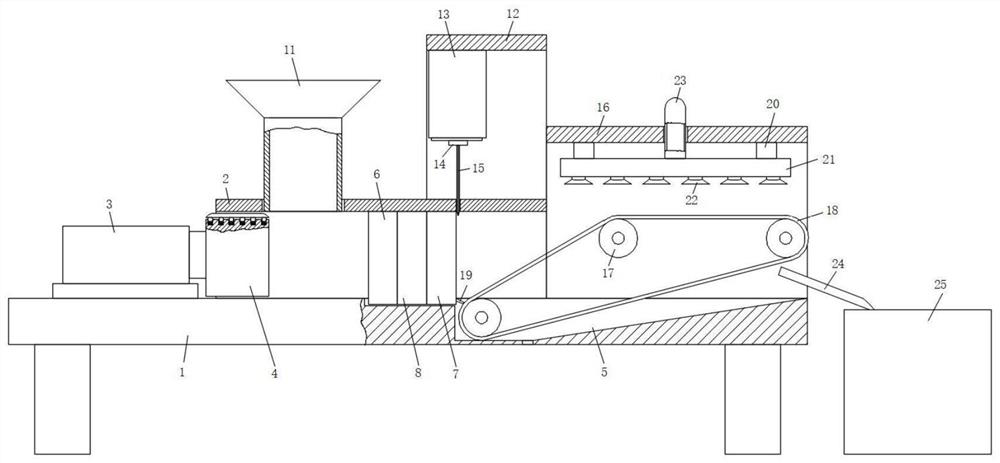

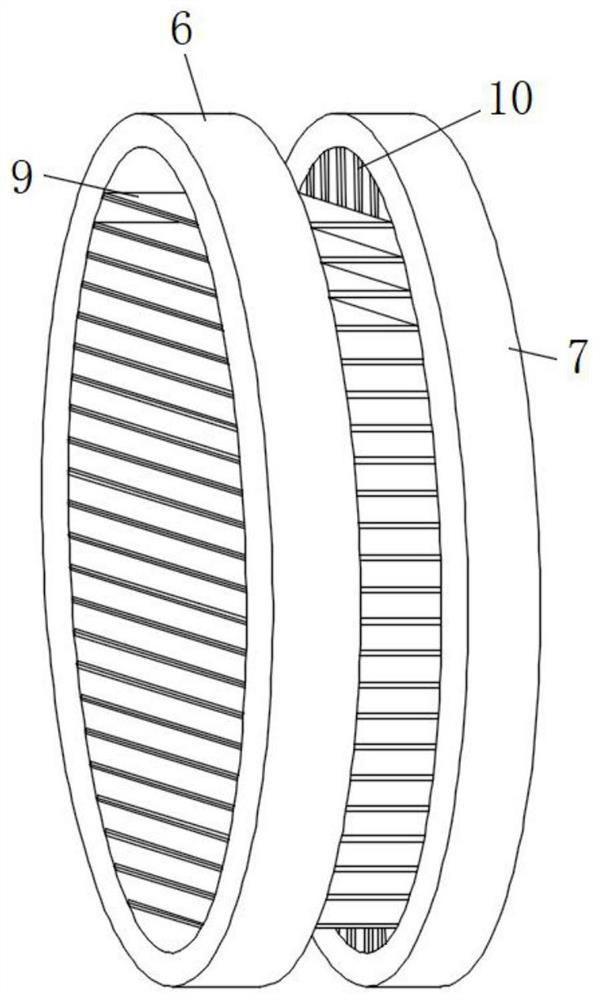

[0031]ReferenceFigure 1-4, A high-efficiency dicing device for Poria pre-processing, comprising a worktable 1, a dicing dish 2 is fixed at the middle of the top surface of the worktable 1, and an electric telescopic rod 3 is fixed on the top side of the worktable 1 by screws. The output ends of the telescopic rod 3 are all fixed with a propulsion component 4 by screws. The propulsion component 4 includes a propulsion block 41. The top of the propulsion block 41 is provided with a blocking plate 42. The bottom surface of the blocking plate 42 is fixed with a connecting column 43 and the top surface of the push block 41 A cylindrical groove is also provided. The propulsion block 41 is slidably connected in the cylindrical groove. A buffer spring 44 is fixed between the connecting column 43 and the bottom surface of the cylindrical groove. A mounting groove is provided on the top surface of the worktable 1 facing away from the electric telescopic rod. 5. The lowest part of the bottom s...

Embodiment 2

[0034]Such asfigure 1 with2As shown, this embodiment is basically the same as Embodiment 1. Preferably, the electric telescopic rod 3, the transverse cutting ring 6, the vertical cutting ring 7, the feeding funnel 11 and the electric telescopic rod 2 13 are all provided with two and distributed In the front and rear positions of the horizontal center plane of the workbench 1.

[0035]In this embodiment, the electric telescopic rod 1 3, the transverse cutting ring 6, the vertical cutting ring 7, the feeding funnel 11 and the electric telescopic rod 2 13 are all provided with two and are distributed on the front and rear sides of the horizontal center surface of the workbench 1. Position, so as to realize the rapid processing of Poria, greatly improving the processing efficiency of Poria.

Embodiment 3

[0037]Such asFigure 4 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the pushing block 41 is fixed to the output end of the electric telescopic rod 3 by screws, and the pushing block 41 is slidably connected to the inner wall of the dicing plate 2 to connect The pillars 43 are provided with multiple and evenly distributed on the bottom surface of the barrier plate 42, and both sides of the top surface of the barrier plate 42 are provided with arc transition sections.

[0038]In this embodiment, a plurality of connecting posts 43 are fixed on the bottom surface of the barrier plate 42 to make the barrier plate 42 move more smoothly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com