Improved raw material mixing and extruding equipment for tile production

An extrusion equipment and improved technology, which is applied in the field of improved brick and tile production raw material mixing extrusion equipment, can solve problems such as low applicability, affecting enterprise benefits, and inability to change production conditions according to demand, and achieve great economic benefits , beautiful appearance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

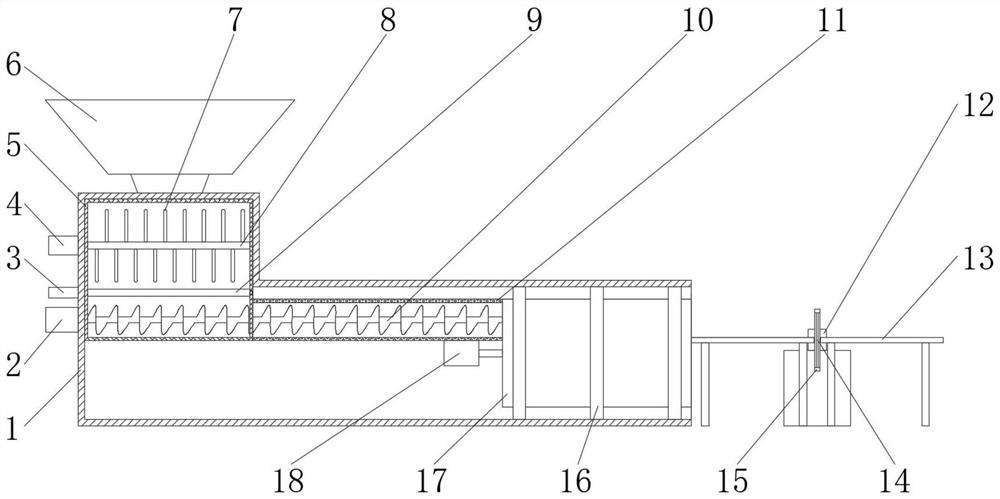

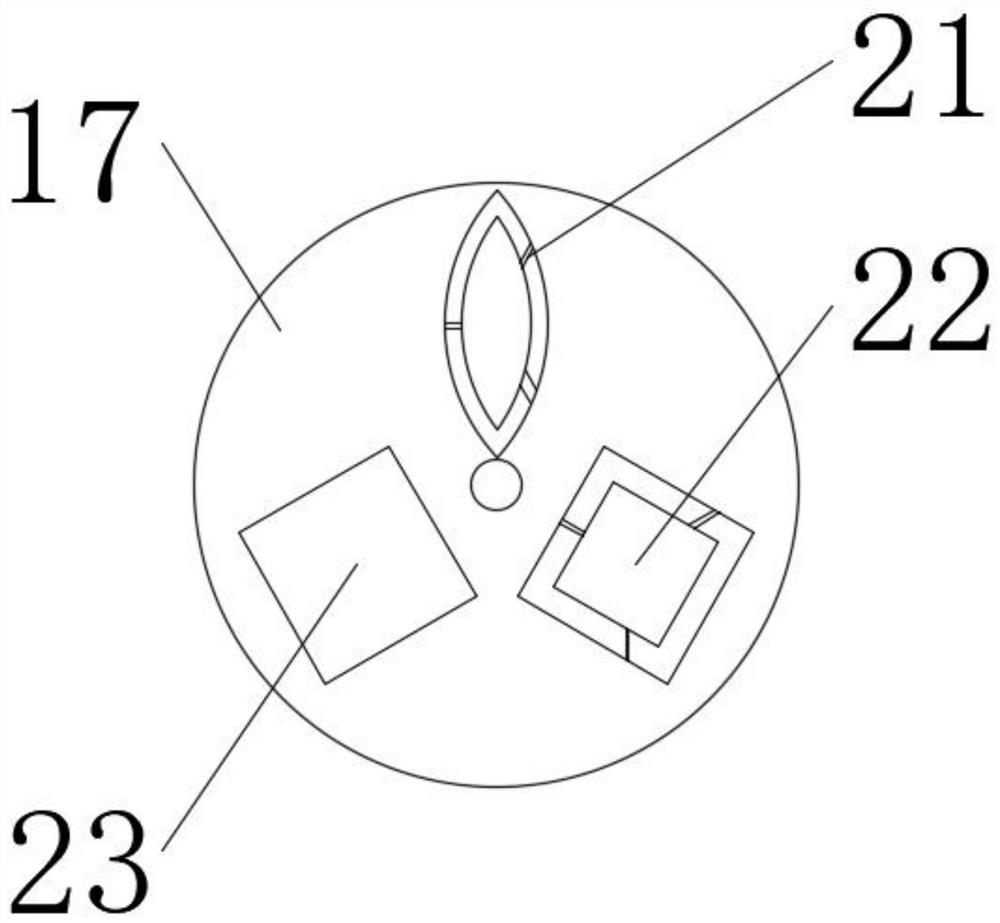

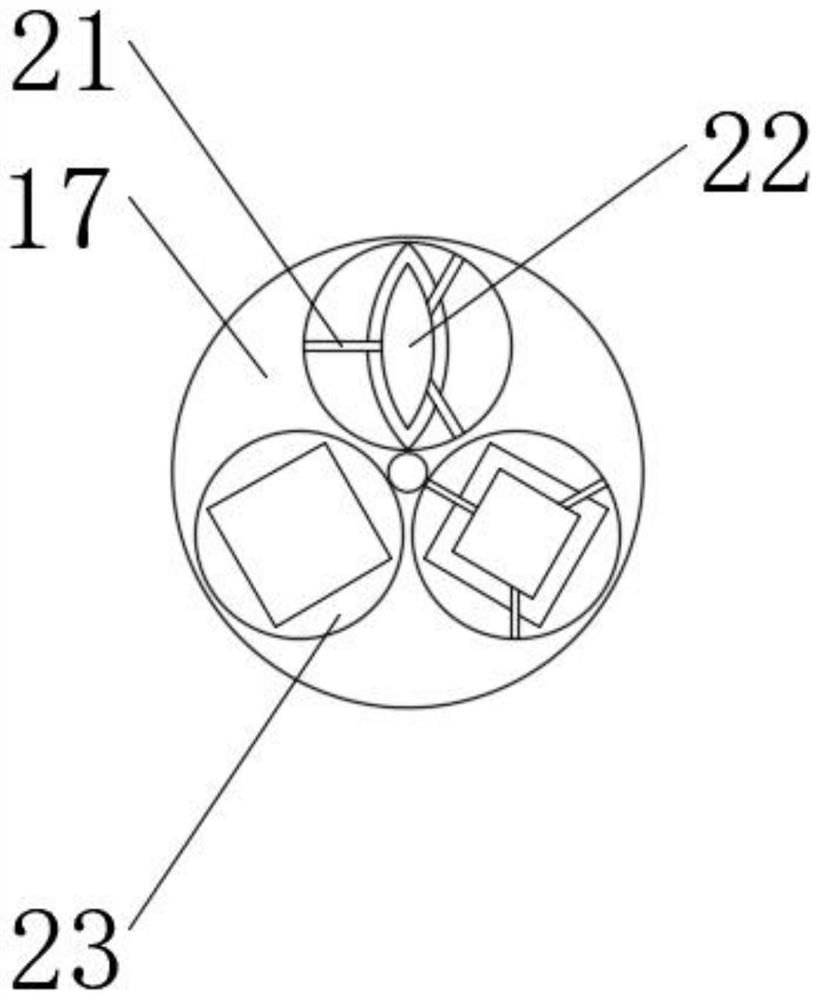

[0028] Such as Figure 1-6 As shown, the embodiment of the present invention provides an improved raw material mixing and extrusion equipment for brick and tile production, including a box body 1, a first motor 2, an adjusting motor 3, a second motor 4, a pre-packed box 6, and a brake cylinder 12 And mold changing motor 18, the inside of box body 1 is provided with mixing box 5, and mixing box 5 is fixedly connected with the inner side wall of box body 1, and the inside of mixing box 5 is provided with installation rod 8, and one end of installation rod 8 is connected with the second motor The driving end of 4 is fixedly connected, the other end of the installation rod 8 is rotationally connected with the inner side wall of the mixing box 5, the outer surface of the installation rod 8 is fixedly connected with a plurality of stirring rods 7, and the bottom of the installation rod 8 is provided with a baffle plate 9, One side of the baffle plate 9 is rotationally connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com