A virtual rail train body structure

A car body structure and virtual track technology, applied in the field of virtual rail train car body structure, can solve problems such as no mature cases, and achieve the goal of simplifying the production and manufacturing process, improving the degree of light weight and design flexibility, and improving the utilization rate of material properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

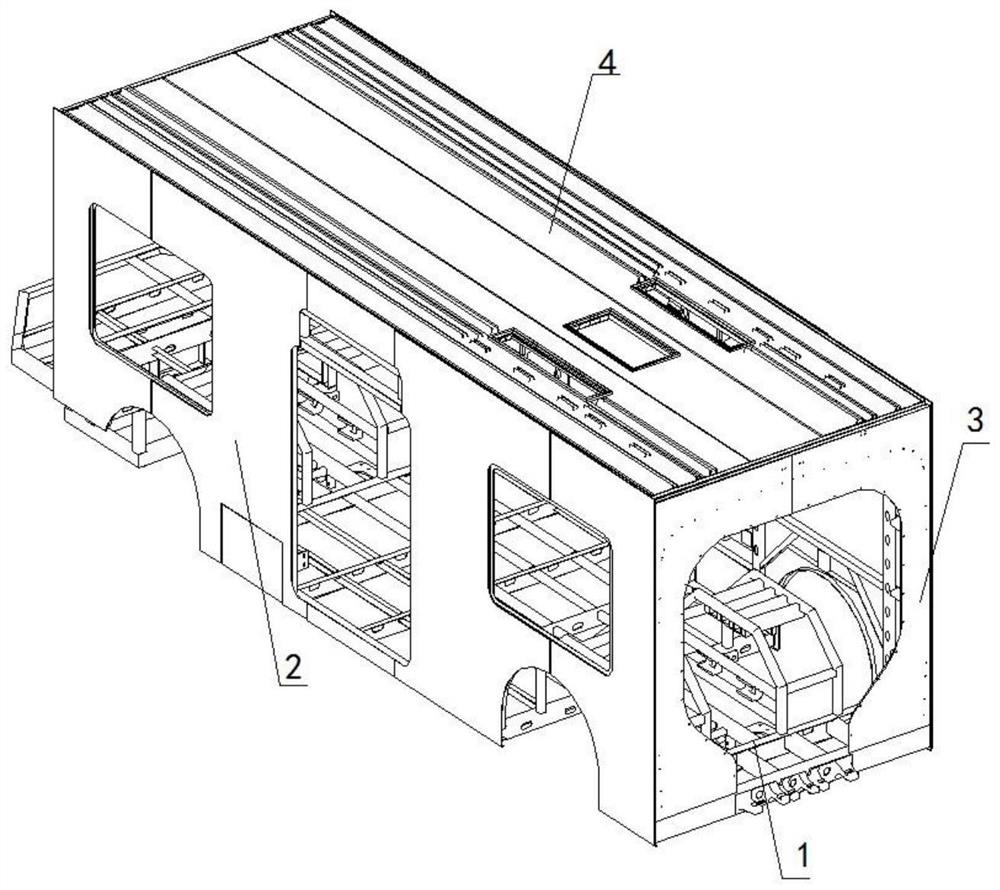

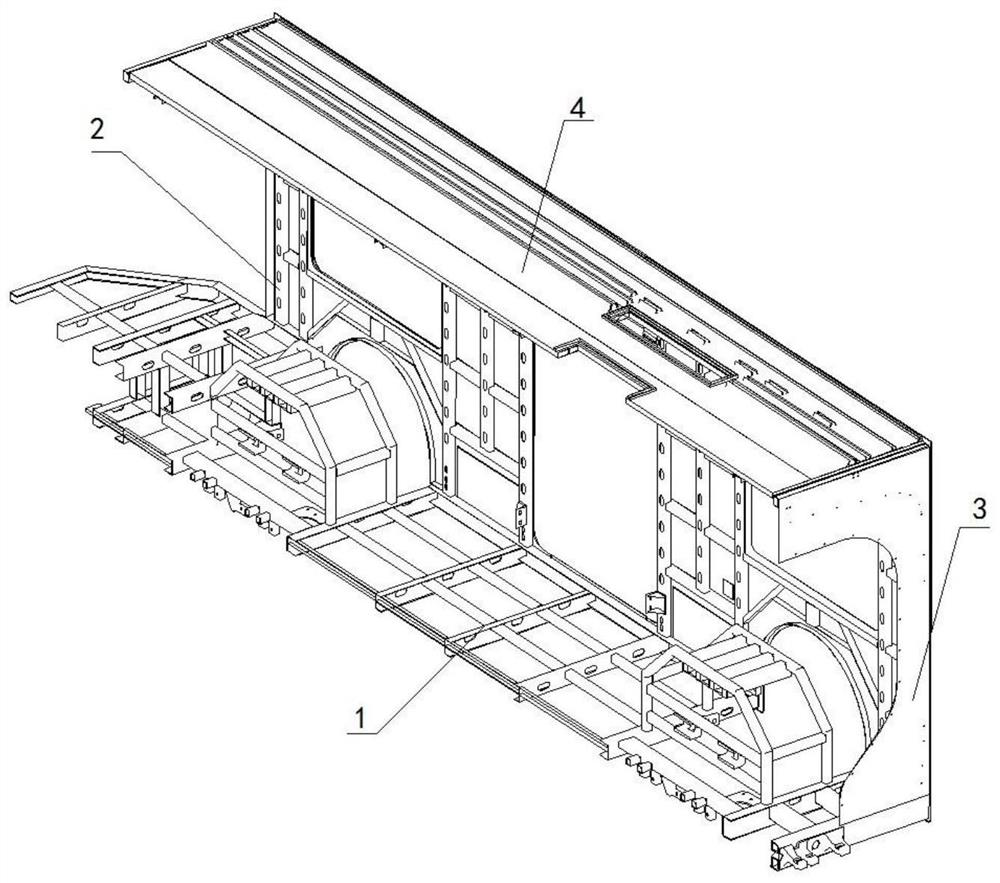

[0027] refer to figure 1 , figure 2 , The car body structure of the present invention mainly includes: an underframe 1, a side wall 2, an end wall 3, and a roof 4.

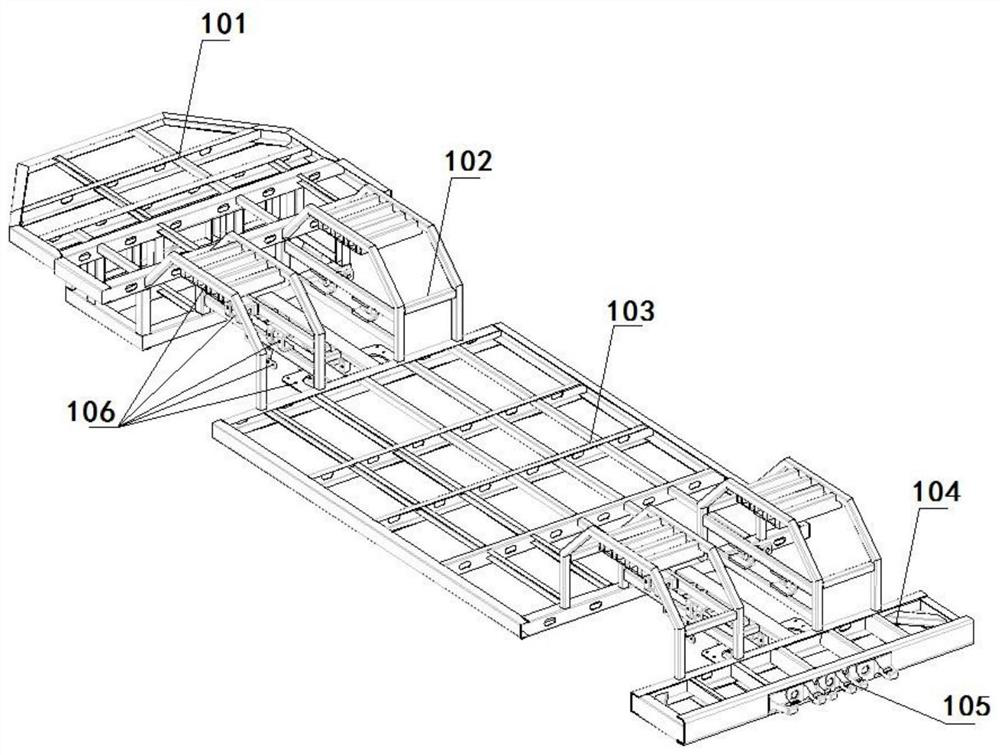

[0028] refer to image 3 and Figure 4 , The underframe 1 of the present invention mainly includes: a first-end underframe 101, a wheel area arch beam 102, a low-floor area skeleton 103, a second-end underframe 104, a hinged support 105, and a suspension interface mounting seat 106. The one-end chassis 101 and the two-position chassis 104 adopt a high-strength truss-type steel skeleton structure, mainly using channel-shaped steel materials and square steel pipes, and lightening holes are set on the beams; the beams are connected by channel-shaped longitudinal beams; the skeleton The upper and lower planes are supported by grooves and square columns; the reasonable arrangement and welding of beams, longitudinal beams, and columns form a truss-type steel skeleton structure arranged in a circle, which realizes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com